Carrying clamp manipulator

A technology of manipulators and fixtures, applied in the direction of manipulators, chucks, manufacturing tools, etc., can solve the problems of lower production efficiency of the assembly line, large equipment costs, and inability to adapt to increasingly diverse carton products, etc., to achieve small footprint and fast conveying speed , the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

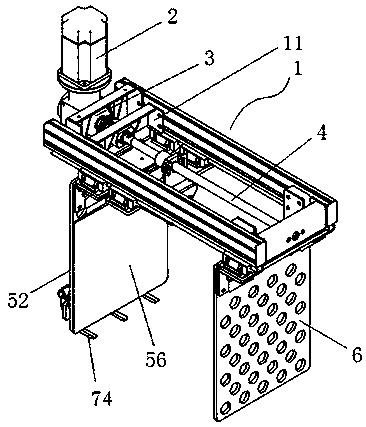

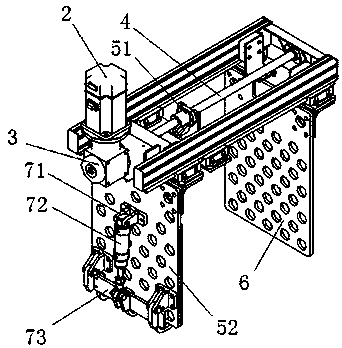

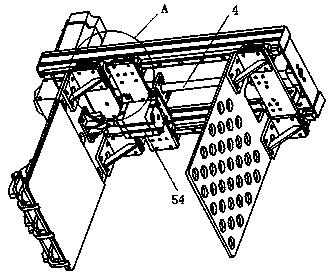

[0021] In order to illustrate the technical scheme of the present invention more clearly, the following will be combined with the attached figure 1 - 6 further describe the present invention.

[0022] A manipulator for handling clamps, comprising: a frame 1, a servo motor 2, a reducer 3, a left and right screw rod 4, a clamping and fixing plate mechanism 5, a clamping plate 6 and an anti-dropping mechanism 7.

[0023] Wherein, the frame 1 is provided with an adjustment screw base 11, and the left and right rotation screw rods 12 are installed on the adjustment screw base 11; the servo motor 1 is connected to the reducer 2 and drives the reducer 2 to work; The reducer 2 is connected to the left and right screw rods 12, and drives the left and right screw rods 12 to rotate; the clamping plate 6 is connected to the right-hand thread section of the left and right screw rods 12;

[0024] The clamping and fixing plate mechanism 5 includes a connecting seat 51, a clamping and fixing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com