Method for reserving lamphole in large-sized panel through gold stamping

A large-size, lamp-hole technology, applied in the printing field, can solve the problems of increasing production costs, low production efficiency, and increased production processes, and achieve the effects of improving production efficiency, eliminating processes, and reducing production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in detail below in conjunction with the accompanying drawings.

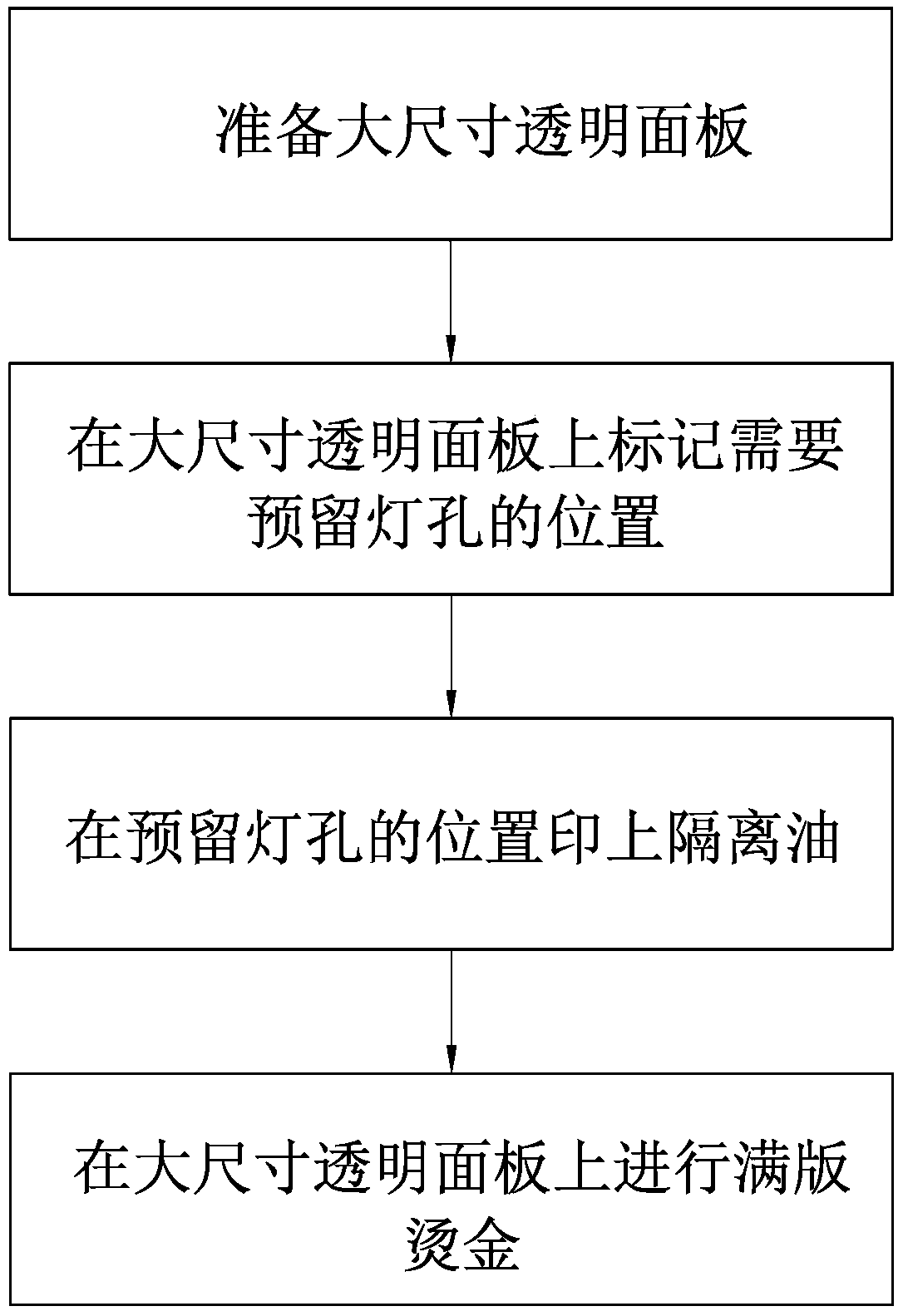

[0016] Such as figure 1 As shown, a large-size panel bronzing method for leaving lamp holes according to the present invention,

[0017] Step 1: Prepare large-size transparent panels;

[0018] Step 2: Mark the positions where light holes need to be reserved on the large-size transparent panel;

[0019] Step 3: Print isolation oil on the position where the lamp hole is reserved;

[0020] Step 4: Carry out full-page bronzing on the large-size transparent panel. The anodized aluminum is in contact with the large-size transparent panel. Transfer the anodized aluminum to the large-size transparent panel where the isolation oil is printed. The hot stamping is It cannot be ironed, so there will be no electrochemical aluminum transfer, and the shape of the lamp hole will be reserved.

[0021] Through the above method for large-size panels to be bronzed and left with lamp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com