Guides and glass cutting systems

A guide device and guide piece technology, which is applied in glass cutting devices, glass production, glass transportation equipment, etc., can solve problems such as collision damage, liquid crystal glass substrate scratches, etc., and achieves convenient installation and use, convenient manufacturing and processing, and simple structure reasonable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

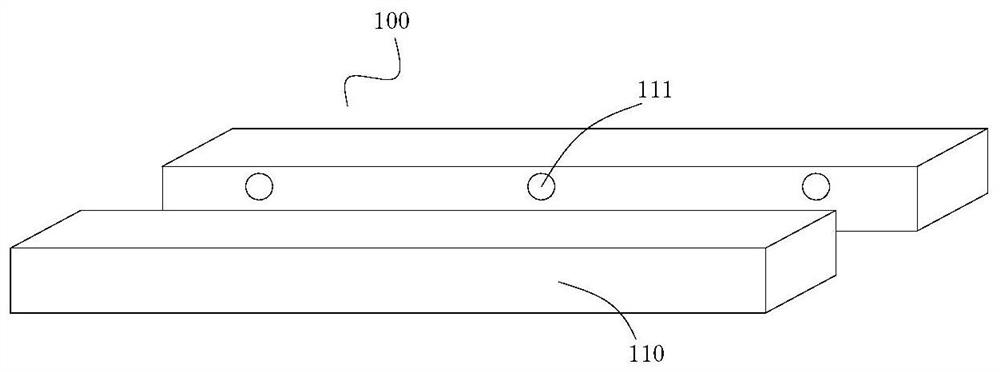

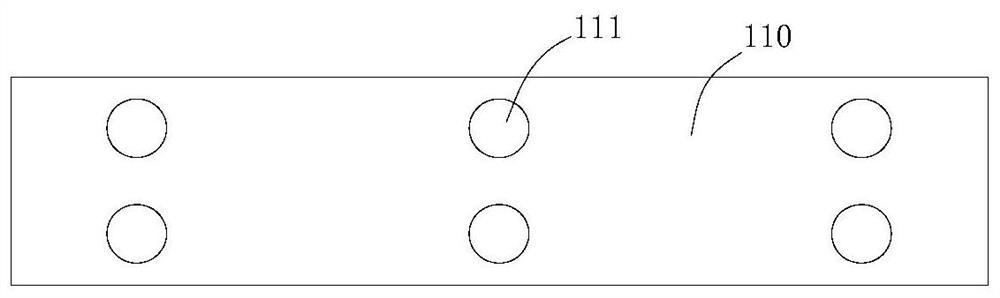

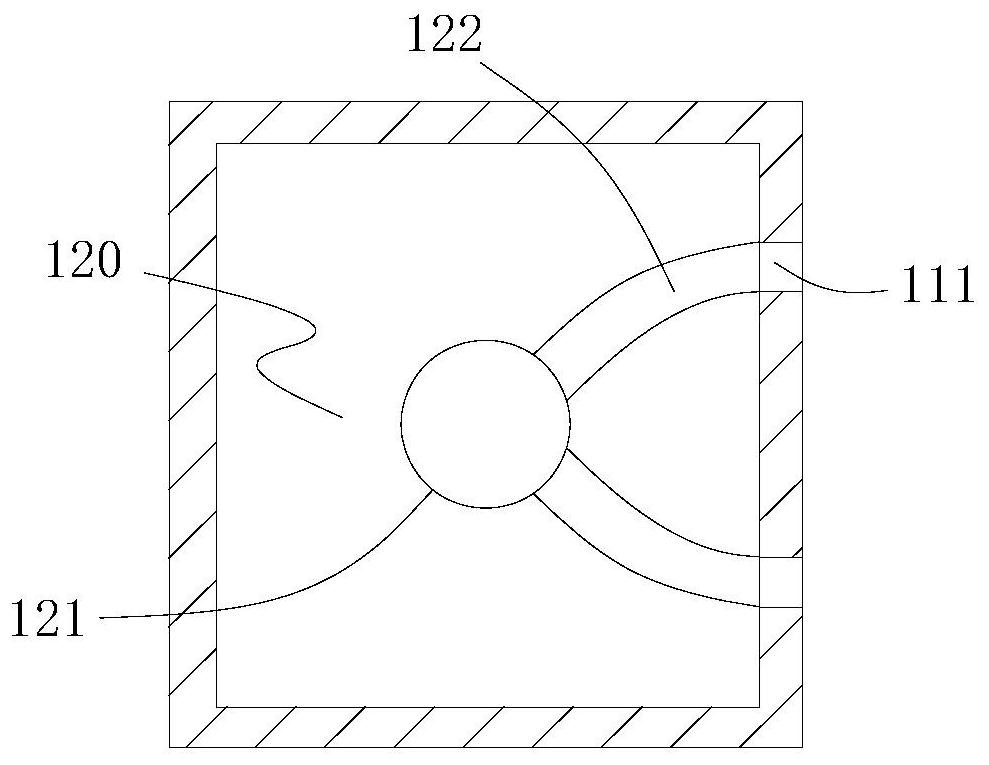

[0039] see figure 1 - Figure 6 , this embodiment provides a guide device for use in conjunction with the transport unit 400 of the liquid crystal glass substrate 001 to ensure that the liquid crystal glass substrate 001 is stable and reliable during transportation, and is not prone to problems such as scratches and collision damage due to shaking.

[0040]The guiding device provided in this embodiment includes two guiding units 100, and the two guiding units 100 are arranged in pairs. Each guiding unit 100 includes a guiding piece 110 and an air supply assembly 120. The guiding piece 110 is provided with an air outlet 111 for supplying air. The air outlet of the gas assembly 120 communicates with the air outlet hole 111, and the two guides 110 of the paired guide unit 100 are arranged opposite to each other, and a guide channel for positioning the liquid crystal glass substrate is defined between the two guides 110.

[0041] The guide device provided in this embodiment is us...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com