Variable diameter ball seat type full diameter soluble fracturing sliding sleeve

A fracturing sliding sleeve and full-bore technology, which is applied in the direction of production fluid, wellbore/well components, earthwork drilling and production, etc., can solve problems such as complex operations of bridge plugs, and achieve a wide application range, simple structure, and reliable operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

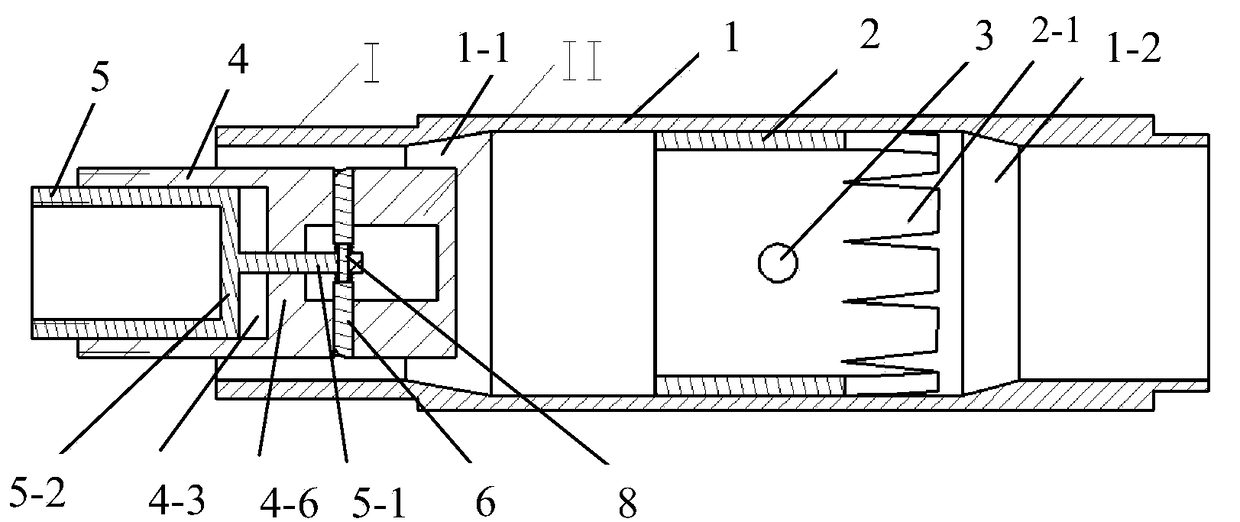

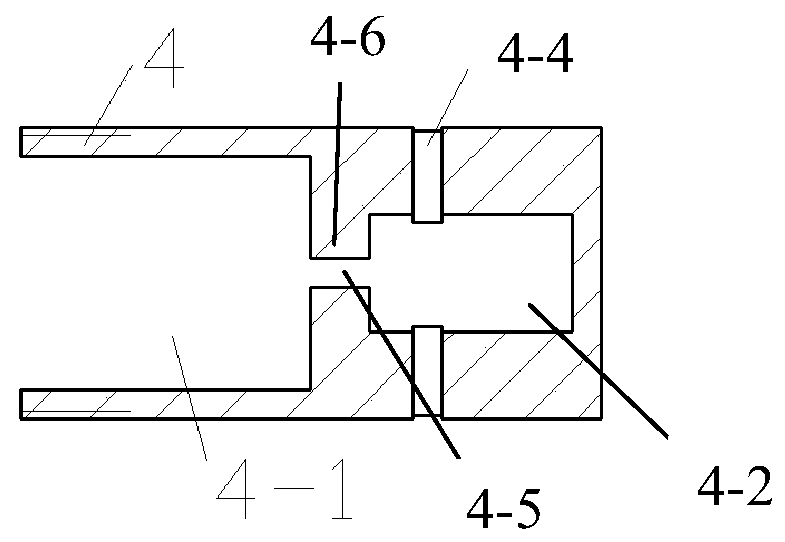

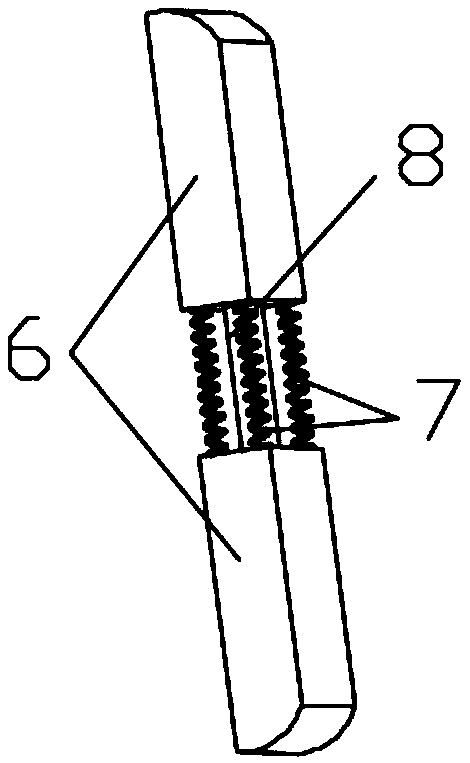

[0025] Such as Figure 1-3 As shown, the variable-diameter ball seat type full-diameter soluble fracturing sleeve of the present invention includes a ball seat former II, a casing short I, and a soluble fracturing ball 9, and the casing short I includes a short body 1. The variable-diameter ball seat 2 of soluble material, the inner diameter of the short-circuit body 1 is a variable-diameter cylinder with small ends and a large middle, and the transition sections between the large-diameter section in the middle and the small-diameter sections at both ends are respectively provided with upper guiding slope sections 1-1 and the lower guide slope section 1-2; the lower part of the reducing ball seat 2 is an annular structure with multiple axial gaps 2-1, and the reducing ball seat 2 is fixed on the large part of the shorting body 1 by the fixing pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com