Internal injection replacement support room type coal pillar recovery method

A room-type coal pillar and recovery method technology, which is applied in pillars/supports, earth cube drilling, ground mining, etc., can solve the problems of low recovery rate, cost of a large amount of filling materials and equipment investment, low degree of mechanization, etc., to achieve Recycling coal resources, reducing risks such as fire and spontaneous combustion, and strong applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

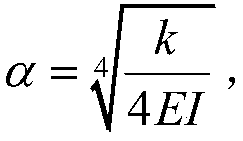

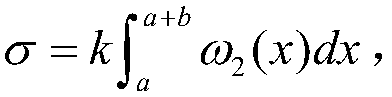

[0084] According to the above solution method, combined with the geological conditions of a mine in Northwest China as an example, the roof thickness of the mine is 2m, the mining height is 4m, the length of the coal pillar is about 10m, the length of the coal room is about 7m, the elastic modulus of the roof is 0.9GPa, and the coal foundation Factor 2×10 6 N / m 3 , The allowable tensile stress of the roof is 2.8MPa, the ultimate strength of the reserved coal pillar is 49.3MPa, and the uniform load q=2MPa is taken. Judging by formula (v), when the reserved coal pillar width is 3m, the roof bending moment distribution is as follows: Figure 5 As shown, the maximum tensile stress on the roof at this time reaches 2.2MPa, and the roof will not break, and the pressure curve of the coal pillar is drawn, see Image 6 , it can be known from formula (vi) that the resultant force acting on the coal pillar at this time reaches 21.7MPa, the width of the currently reserved coal pillar (2)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com