Water turbine

A technology for water turbines and runners, applied in hydropower, mechanical equipment, engine components, etc., can solve the problems of high cost of seals, difficult to ensure assembly accuracy, high maintenance costs, etc., to reduce axial force, simple and reliable structure , the effect of reducing the difficulty of assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

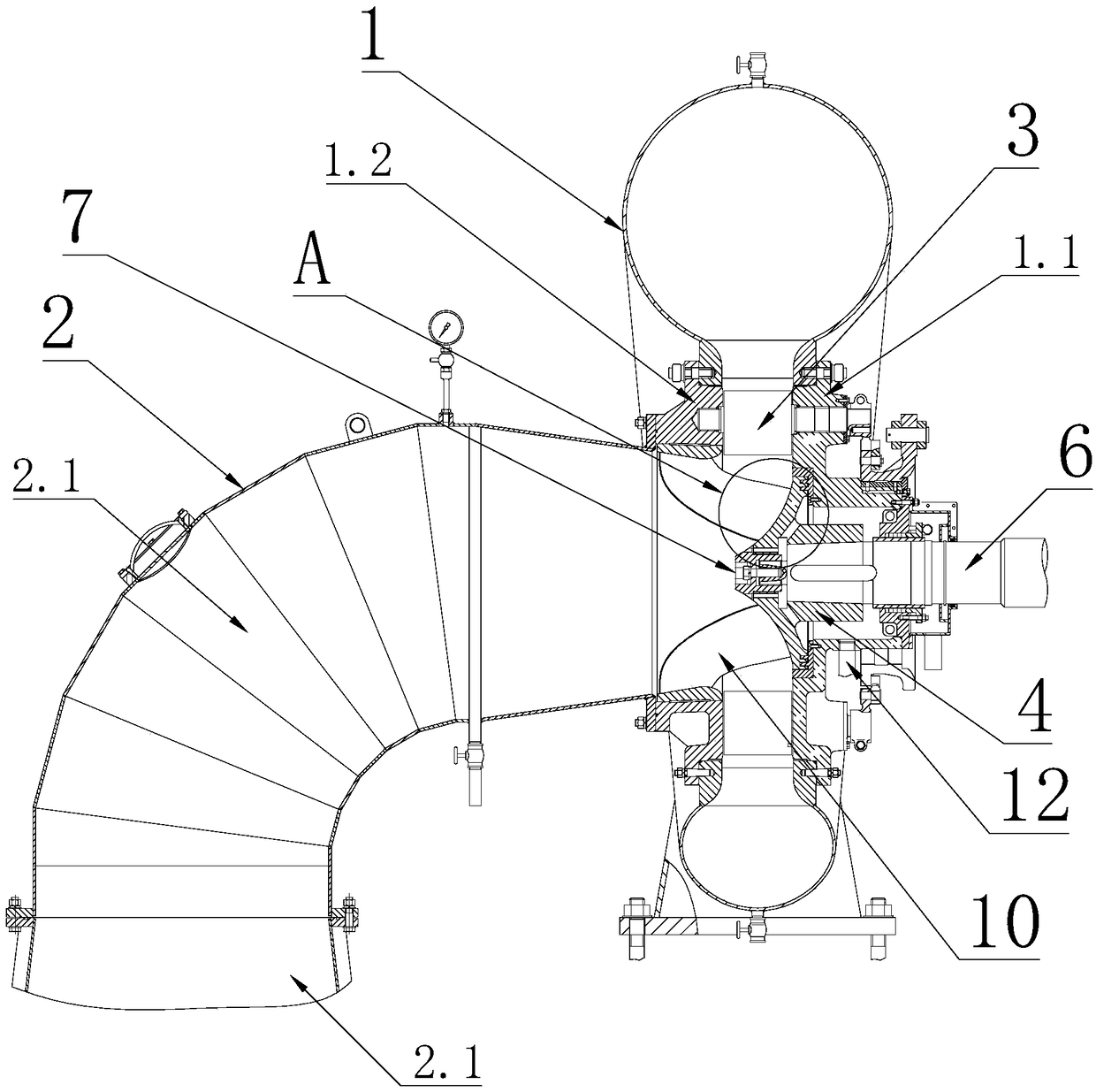

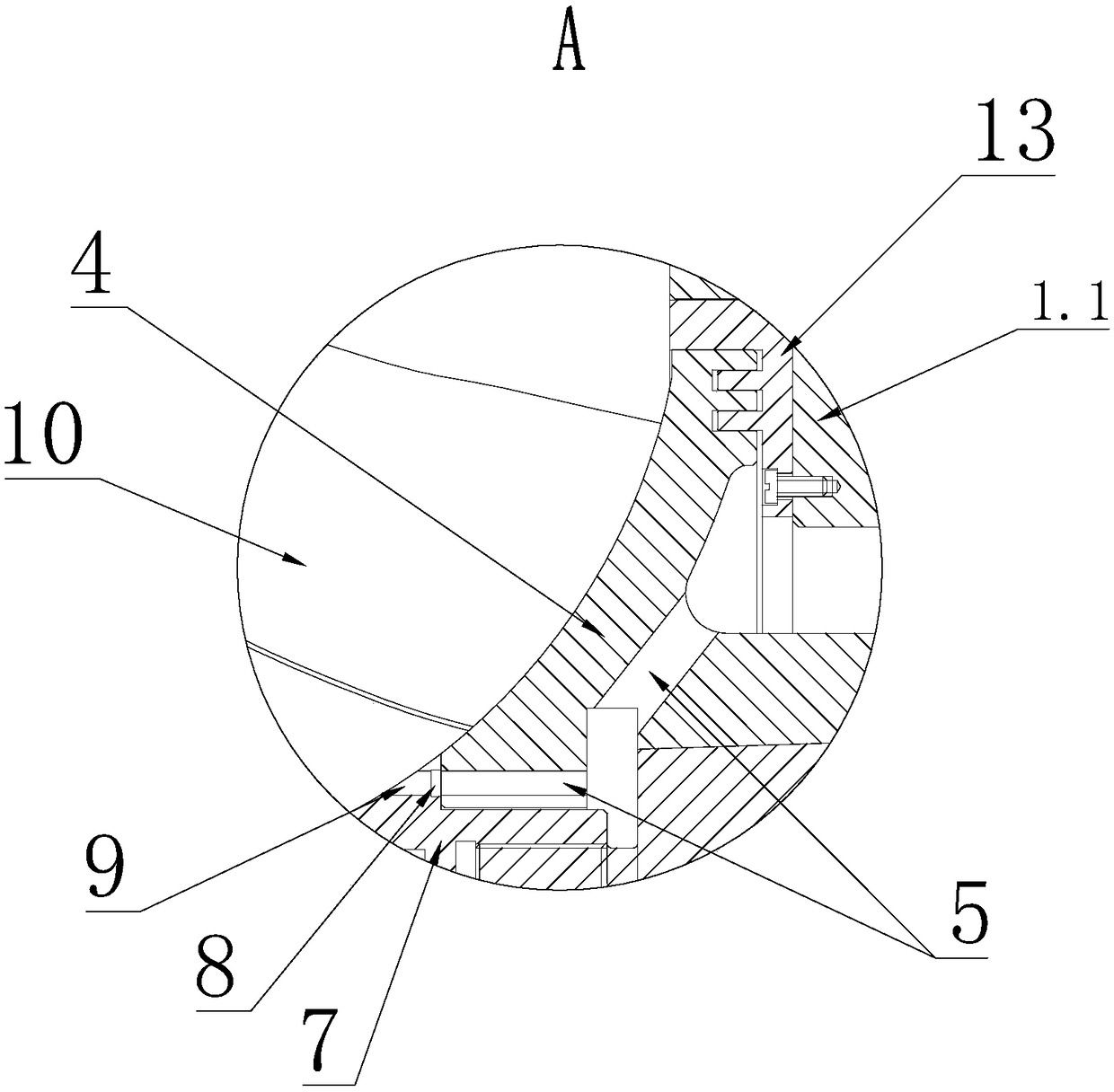

[0029] The invention provides a water turbine, which includes such as figure 1 As shown in the volute 1 and the draft tube 2, the outer wall of the volute 1 is provided with a water inlet, and the center of the volute 1 is provided with a water outlet 3, and the draft tube 2 and the water outlet 3 of the volute 1 Connected so that the pipeline in the volute 1 communicates with the draft tube 2 to form a water flow channel, the pipeline in the volute 1 is in a spiral shape, and the volute 1 is provided with a runner 4, and the runner 4 and The volute 1 rotates and fits, and the volute 1 is provided with a mounting groove for installing the runner 4. When the runner 4 rotates and fits in the mounting groove, the part of the runner 4 is located in the water flow channel and passes through the water flow channel. The flow of the water flow drives the runner 4 to rotate, so that the water flow in the volute 1 can be converted into the mechanical energy of the runner 4 . The runner...

Embodiment 2

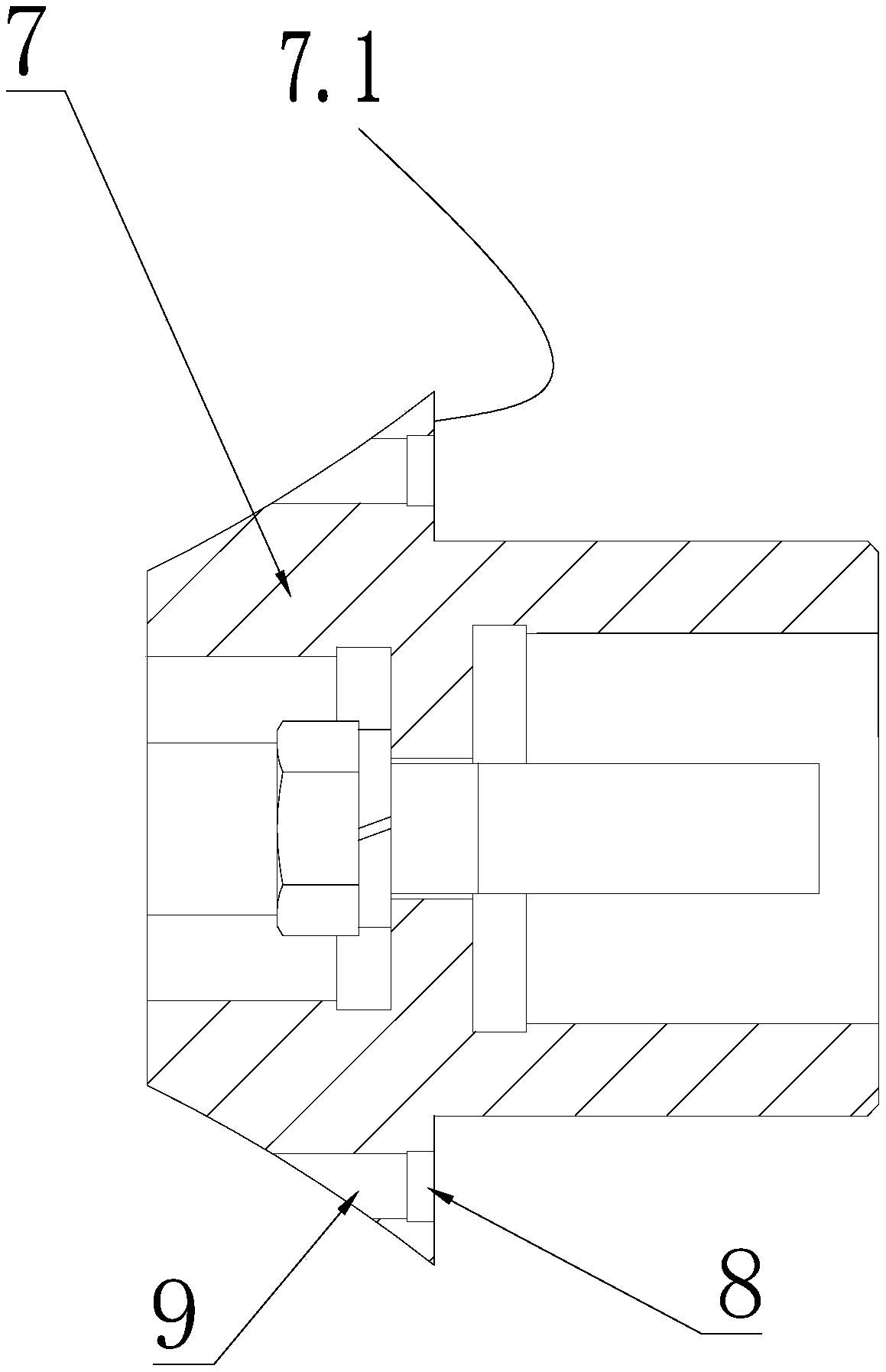

[0031] Its basic mechanism is the same as that of Embodiment 1, the difference is that: the rear end surface 7.1 of the water discharge cone 7 facing the runner 4 is provided with a plurality of arc-shaped grooves 8, and all arc-shaped grooves 8 are arranged along the circumferential direction. They are arranged at intervals in sequence, and any two adjacent arc-shaped grooves 8 are connected through a connecting groove 11 , and the cross-sectional area of the connecting groove 11 is smaller than that of the arc-shaped groove 8 . Preferably, the cross-sectional area of the connecting groove 11 is equal to the cross-sectional area of 1 / 4 arc-shaped groove 8 . The core purpose of this design is to make a single pressure relief pipeline on the runner 4 correspond to a respective groove 8, thereby corresponding to a respective connecting pipe 9, and a plurality of connecting pipes 9 are not designed in parallel in the runner 4, through The dislocation distribution of the con...

Embodiment 3

[0033] Its basic mechanism is the same as that of Embodiment 2, the difference is that: the draft pipe 2 includes a tail water main pipe 2.1 and a tail water elbow 2.2, and the tail water main pipe 2.1 passes through the tail water elbow 2.2 and the water outlet of the volute 1 3 connected.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com