Single body separation finger type diaphragm spring

A diaphragm spring and separation finger technology, applied in the direction of springs, leaf springs, springs/shock absorbers, etc., can solve problems such as complex structures, high requirements for matching accuracy of connecting parts, and difficulty in ensuring matching accuracy, and achieve small size, Good self-positioning and the effect of reducing manufacturing process requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

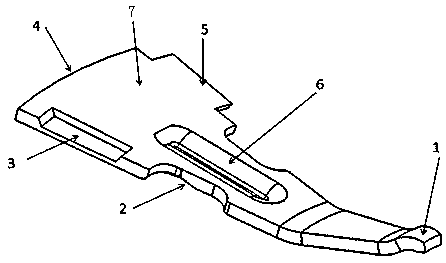

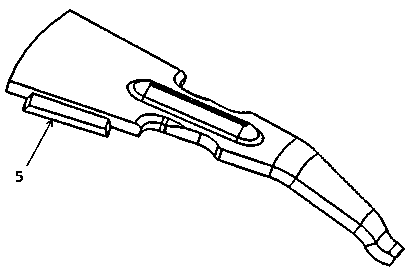

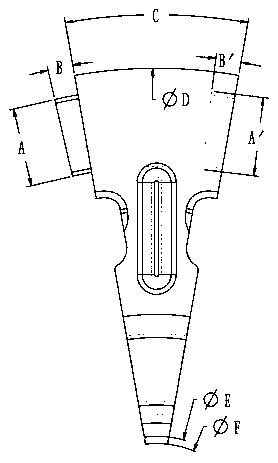

[0036] like Figure 1-4 As shown, the present invention provides a single-separated finger-type diaphragm spring. Multiple single-separated finger-type units are combined into a complete disc-shaped diaphragm spring through mortise and tenon or buckle. The elastic force values of the body-separated finger units are the same or different, and the single-separated finger units with different elastic force values are placed at intervals, and the outer edge 4 of the disc-shaped diaphragm spring is on the same diameter circle. like Figure 4 As shown, the combined disk diaphragm spring is composed of øD in the figure to form the largest outer circle, øE to form the separation finger contact circle, and øF to form the smallest inner circle.

[0037] like figure 1 and figure 2 As shown, the single-separated finger unit includes a finger end 1 and a w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com