Long-distance pipeline anticorrosion device and method

An anti-corrosion device and long-distance technology, applied in the direction of coating, etc., can solve problems such as pipeline corrosion, and achieve the effects of avoiding corrosion, reducing anti-corrosion blind spots, and avoiding pipeline corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in detail below in conjunction with the accompanying drawings and specific examples.

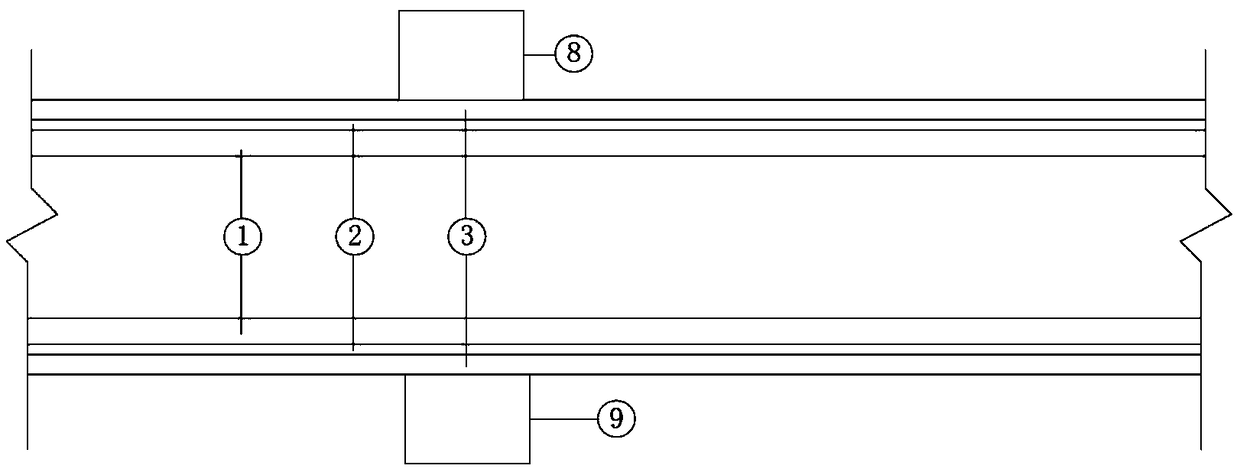

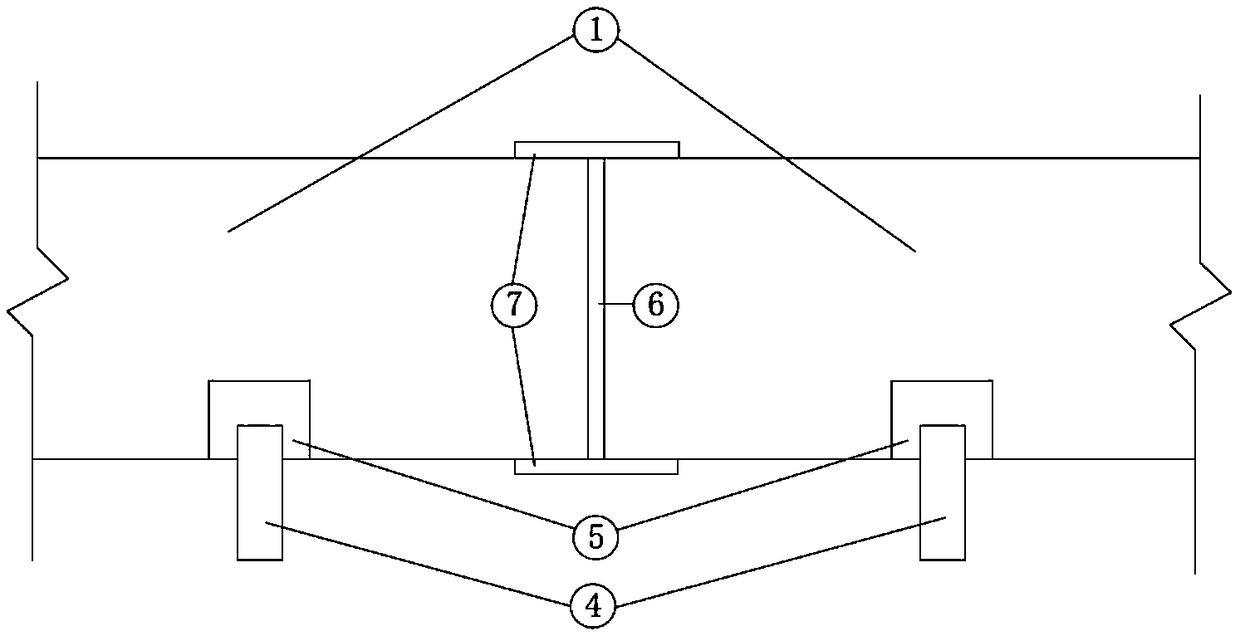

[0020] As shown in the figure, the device of the present invention includes: conveying pipeline (1), anti-corrosion layer (2), protective layer (3), pipe pier (4), isolation plate (5), rubber layer (6), heat shrinkable Pipe (7), detectors 1, 2 (8, 9), the anti-corrosion layer (2) is an anti-corrosion paint, which is applied on the surface of the delivery pipeline (1); the protective layer (3) is flexible and has a certain degree of elasticity , can tightly wrap the delivery pipeline (1), and is located outside the anti-corrosion layer (2), and the protective layer (3) also contains mineral wool and polyurethane foam insulation materials, so it has the functions of preventing mechanical collision and heat preservation; the pipe pier (4) is formed by pouring concrete, located below the conveying pipeline (1), and supports the conveying pipeline (1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com