Working medium filling method for high-temperature heat pipe

A high-temperature heat pipe and working medium technology, applied in indirect heat exchangers, lighting and heating equipment, etc., to achieve the effect of not being easy to oxidize, avoid welding of different materials, and small heat-affected area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to make the above objects, features and advantages of the present invention more comprehensible, specific implementations of the present invention will be described in detail below in conjunction with the accompanying drawings.

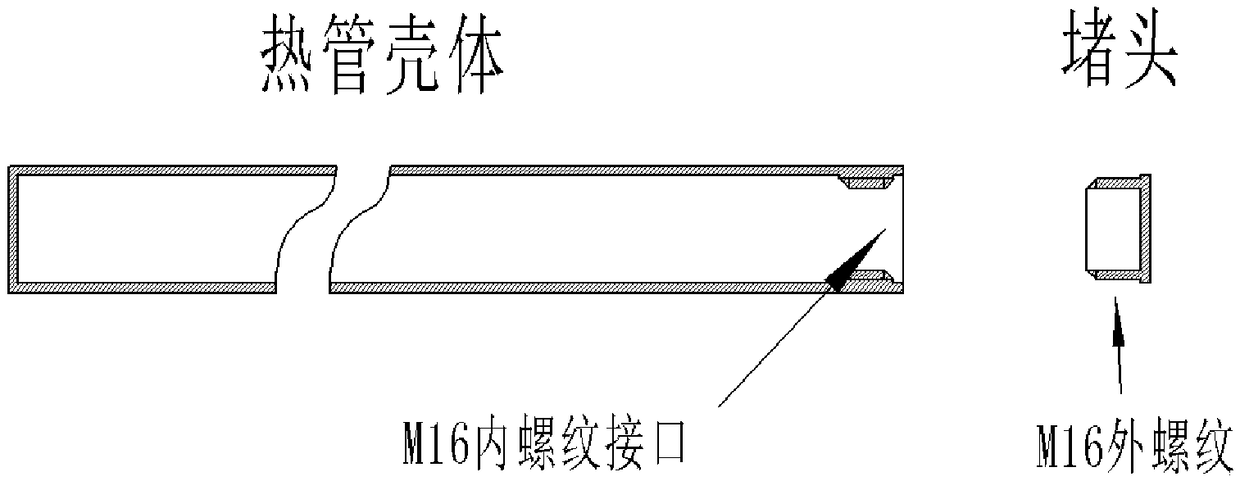

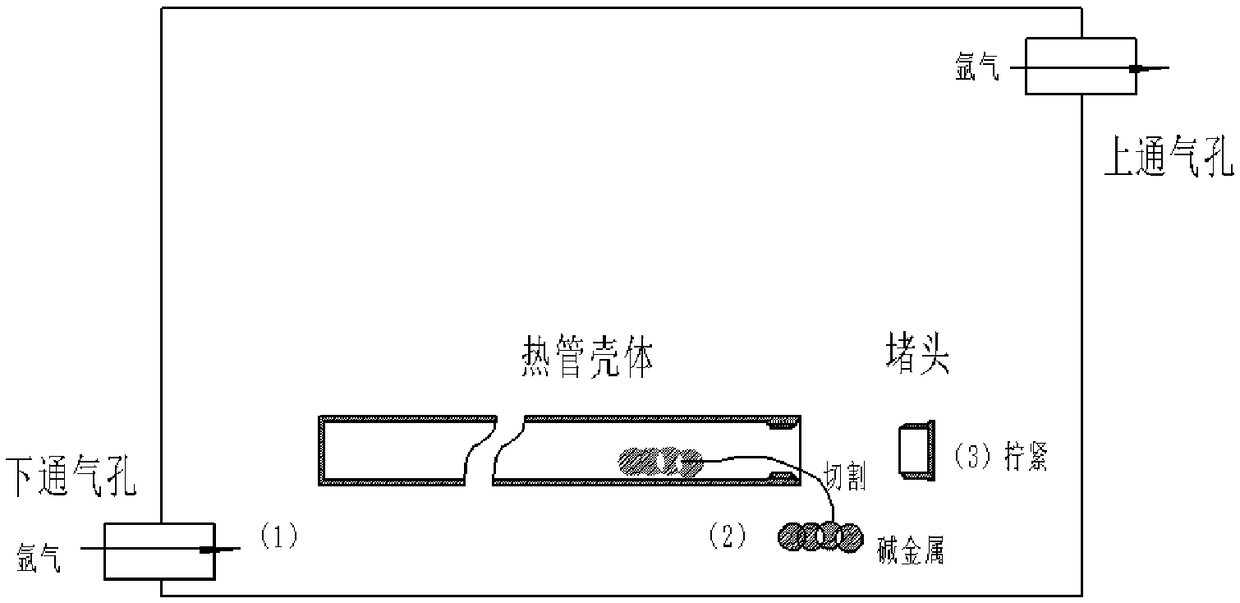

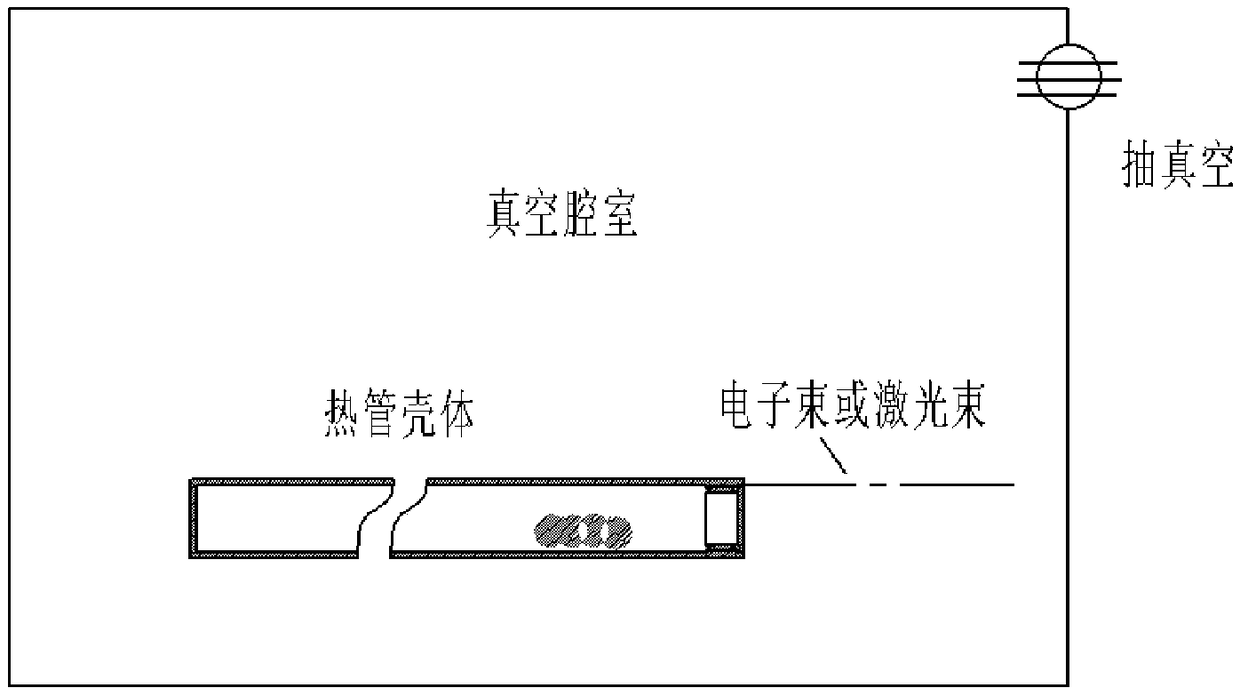

[0032] Such as figure 1 , shown in Fig. 2 (a) and Fig. 2 (b), the present invention provides a kind of filling method of high-temperature heat pipe working fluid, comprises the following steps: process an internal thread interface on the high-temperature heat pipe shell, and process corresponding size (2) Put the high-temperature heat pipe shell into a glove box with a vent hole, and pass a sufficient amount of argon into the glove box and the high-temperature heat pipe shell through the vent hole and the internal thread interface; (3) put the high-temperature heat pipe shell into the glove box; Cut the sodium working fluid in the box, put the cut sodium working fluid into the high-temperature heat pipe shell through the internal threa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Gap | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com