Electric Vehicle Steering Wheel Position Sensor

An electric vehicle, steering wheel technology, applied in the direction of converting sensor output, instruments, measuring devices, etc., can solve the problems of installation and calibration complexity, complex calculation formula, etc., to achieve high reliability, simple mechanical structure, strong anti-interference ability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

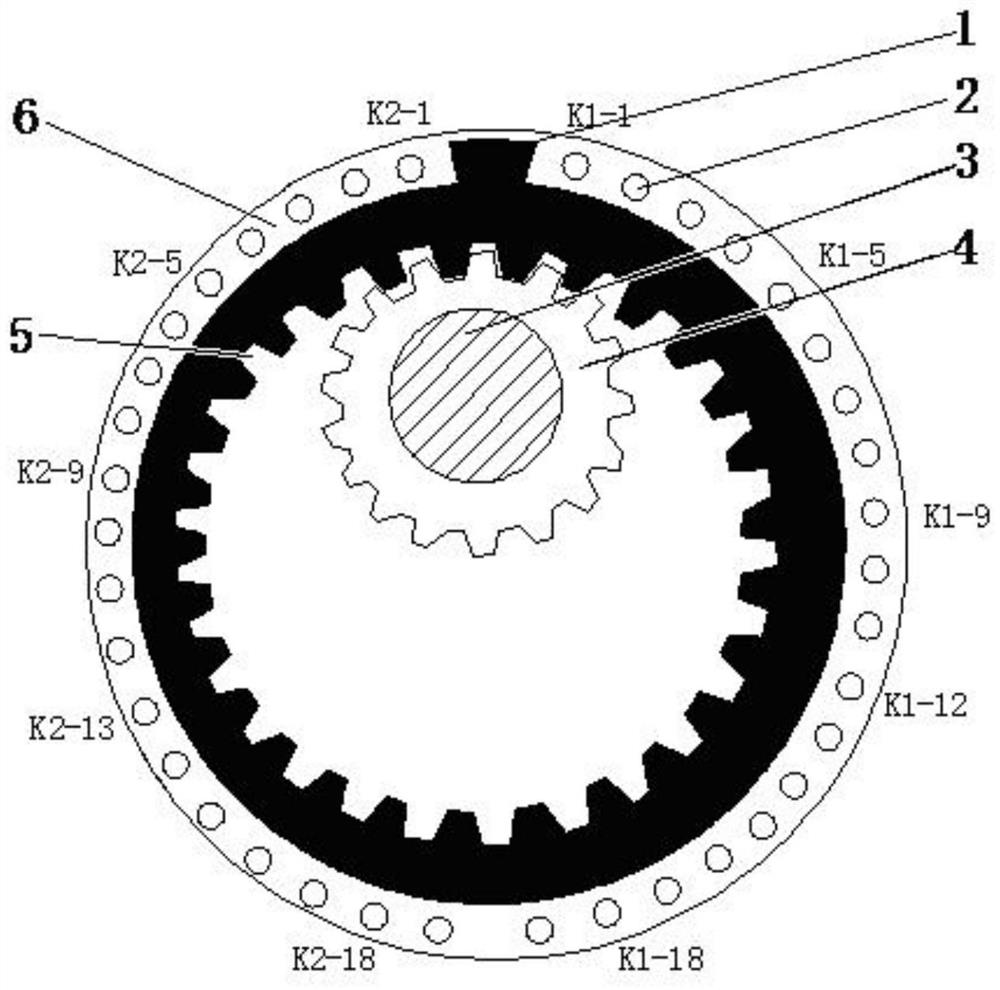

[0038] Such as Figure 1-6 As shown, the electric vehicle steering wheel position sensor of the present invention includes:

[0039] The external tooth pinion 4 is located at the innermost side of the position sensor body, the external tooth pinion 4 is set on the steering wheel shaft 3, and can rotate synchronously with the steering wheel shaft 3;

[0040] The large internal tooth gear 5 is located outside the external tooth pinion 4, and is meshed and rotationally connected with the external tooth pinion 4;

[0041] The number of teeth of the internal tooth bull gear 5 is three times that of the external tooth pinion gear 4;

[0042] The shading plate 1 is connected to the outer edge of the internal gear 5 and moves synchronously with the internal gear 5;

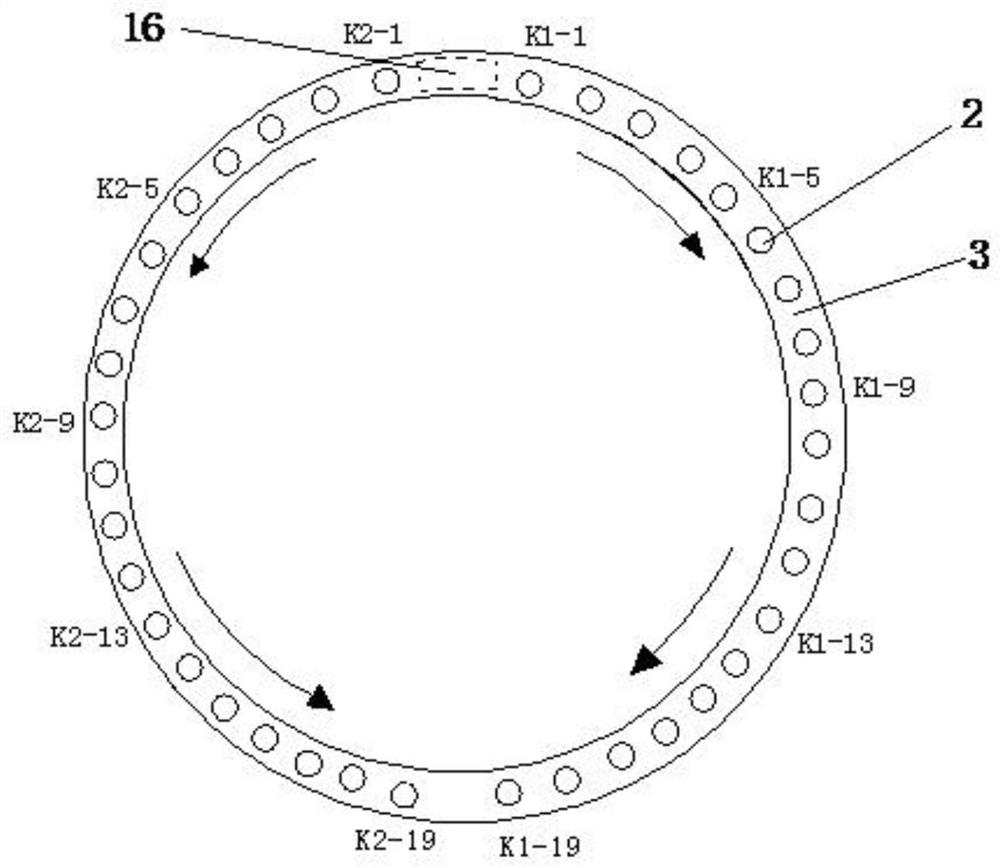

[0043] The position detection ring 6 is located on the outer side of the internal tooth gear 5, and a plurality of photoelectric gates 2 are placed symmetrically and evenly on the left half ring and the right half ring ...

Embodiment 2

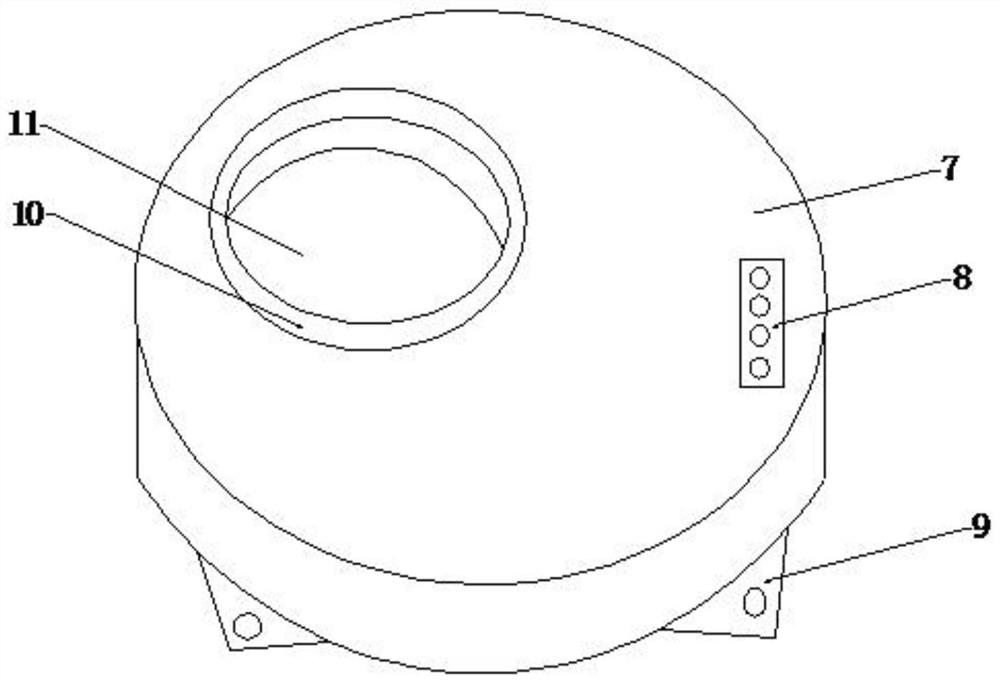

[0066] Such as Figure 7 Shown is an application example of the electric vehicle steering wheel position sensor described in the present invention in implementing the electronic differential function on a two-wheel drive electric vehicle, including the electric vehicle steering wheel position sensor, and also includes a decoder, and the decoder is connected to the steering wheel position sensor , used to decode the detection signal output by the steering wheel position sensor, the output of the decoder is connected to the central controller on the electric vehicle, and the central controller is connected to the left motor and the right motor.

[0067] In order to further illustrate the above embodiment, the decoder includes a first decoder and a second decoder, which are respectively connected to the left half-ring output end and the right half-ring output end of the position detection loop 6 .

[0068] The working principle of the present embodiment is as follows: here, the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com