Heat conductivity coefficient and heat diffusivity transient body heat source measuring method

A technology of thermal conductivity and thermal diffusivity, which is applied in the field of material thermophysical parameter measurement, can solve the problems of large volume effect thermophysical parameter measurement error, steady-state method is easily affected by edge effects, and large device volume. Short, avoid edge effects, small size effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

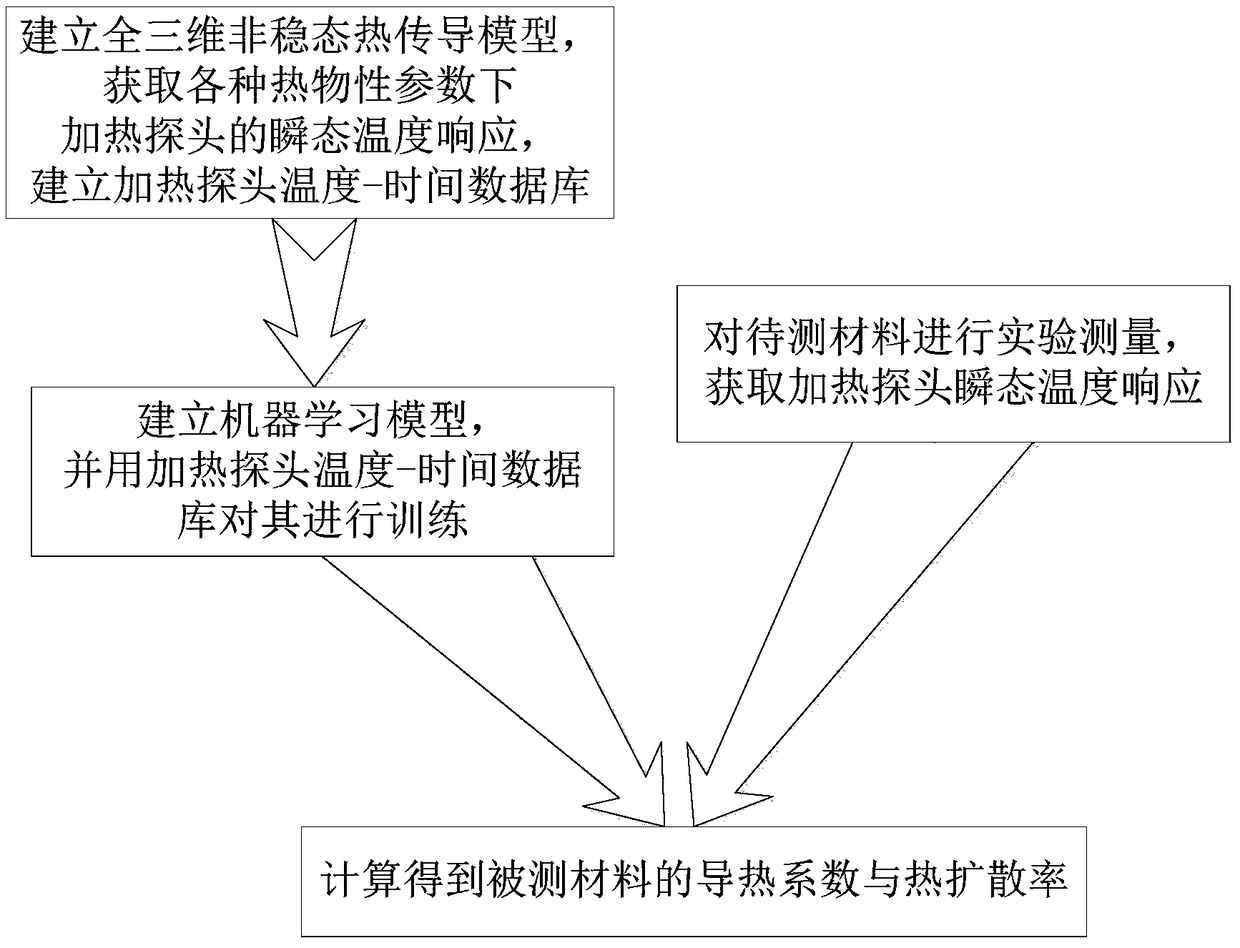

[0049] Specific implementation method: combined image 3 To illustrate this embodiment, the specific process of a transient body heat source measurement method for thermal conductivity and thermal diffusivity in this embodiment is as follows:

[0050] Step 1: Establish a three-dimensional heat transfer model for measuring thermal conductivity; program and calculate the transient average temperature rise of the heating probe under different thermal diffusivity and thermal conductivity based on the three-dimensional heat transfer model, and establish the dimensionless average of the heating probe under different dimensionless thermal physical parameters Excess temperature - dimensionless time database;

[0051] Step 2: Based on the dimensionless average excess temperature-dimensionless time database of the heating probe under different dimensionless thermophysical parameters established in step 1, establish a machine learning model of the thermophysical parameters of the measure...

specific Embodiment approach 2

[0054] Specific embodiment 2: The difference between this embodiment and specific embodiment 1 is: in the step 1, a three-dimensional heat transfer model for measuring thermal conductivity is established; State average temperature rise, and establish the dimensionless average excess temperature-dimensionless time database of heating probes under different dimensionless thermophysical parameters; the specific process is:

[0055] Step 11: Establish a three-dimensional simplified heat transfer model of the experimental device for measuring thermal conductivity. Different from the traditional Hot Disk method, this model fully considers the thickness of the heating probe and the contact thermal resistance between the heating probe and the material to be tested.

[0056] Establish a three-dimensional simplified heat transfer model for measuring thermal conductivity;

[0057] Step 1 and 2: Analyze the heat conduction process of the heat transfer model, and establish the heat conduct...

specific Embodiment approach 3

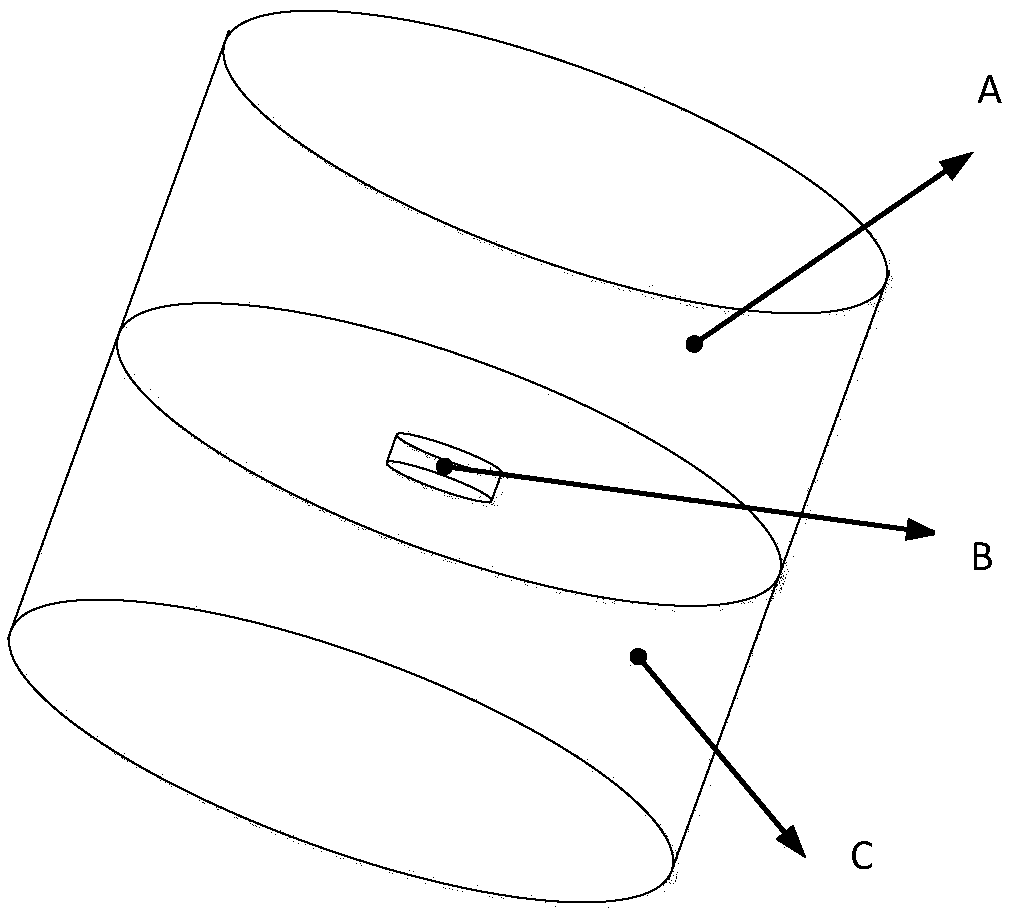

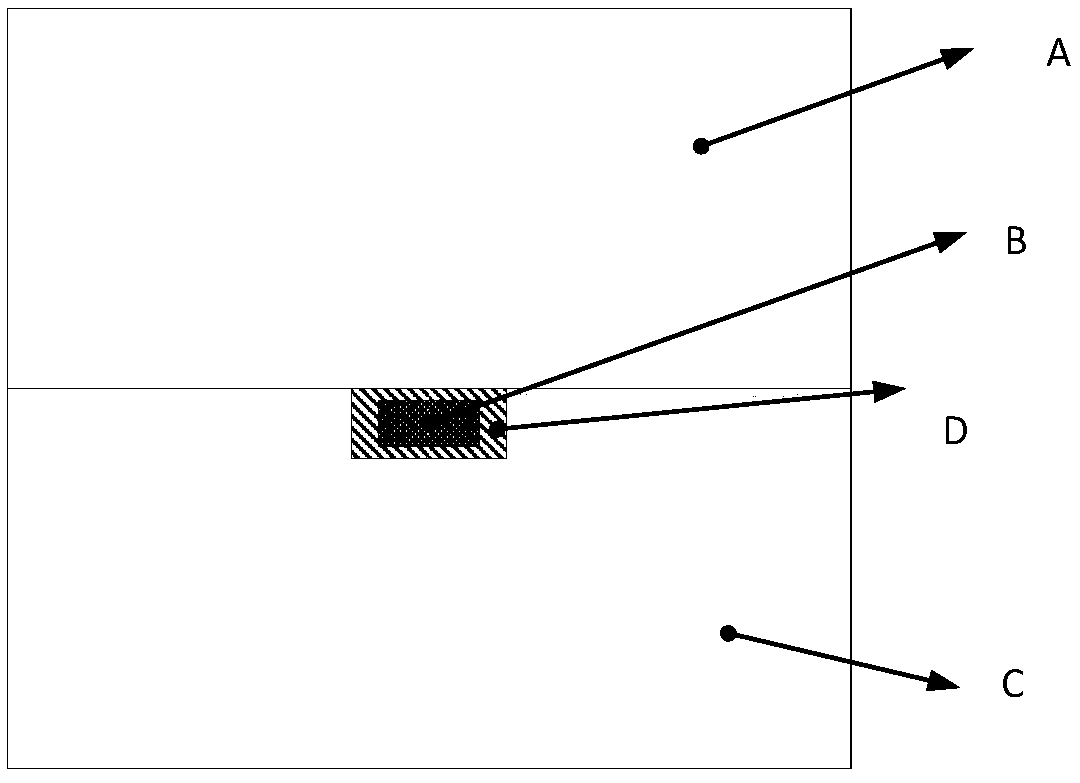

[0094] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is: the full three-dimensional simplified model of the experimental device for measuring thermal conductivity is established in the step one by one, which is different from the traditional Hot Disk method, and the full consideration of this model is The thickness of the heating probe and the thermal contact resistance between the heating probe and the material to be tested; combined figure 1 , figure 2 illustrate;

[0095] Establish a three-dimensional simplified heat transfer model for measuring thermal conductivity, the specific process is as follows:

[0096] The heat transfer model includes three parts: the material to be tested, the base and the heating probe;

[0097] The material to be tested is made into a cylinder;

[0098] The base material is a cylinder with the same size as the material to be tested, and the base material is polycrystalline mullite fiber,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermal conductivity | aaaaa | aaaaa |

| Thermal diffusivity | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com