Construction method of photoelectrochemical sensor for non-labeling detection of 4-chlorophenol

A photoelectrochemical and label detection technology, applied in the field of electrochemical detection, can solve the problems of being unsuitable for low-cost rapid detection, expensive equipment, complicated operation, etc., and achieve the effect of excellent photoelectric activity and rapid detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Step 1, the step of preparing graphite phase carbon nitride (GCN):

[0031] First weigh 0.6g of cyanuric chloride and 15mL of acetonitrile and mix them evenly, slowly transfer 0.1g of melamine into it, and after it is completely dissolved, transfer the resulting solution to an autoclave for solvent heat treatment, and place the autoclave at 140°C. After reacting for 48h, the solid product obtained was GCN.

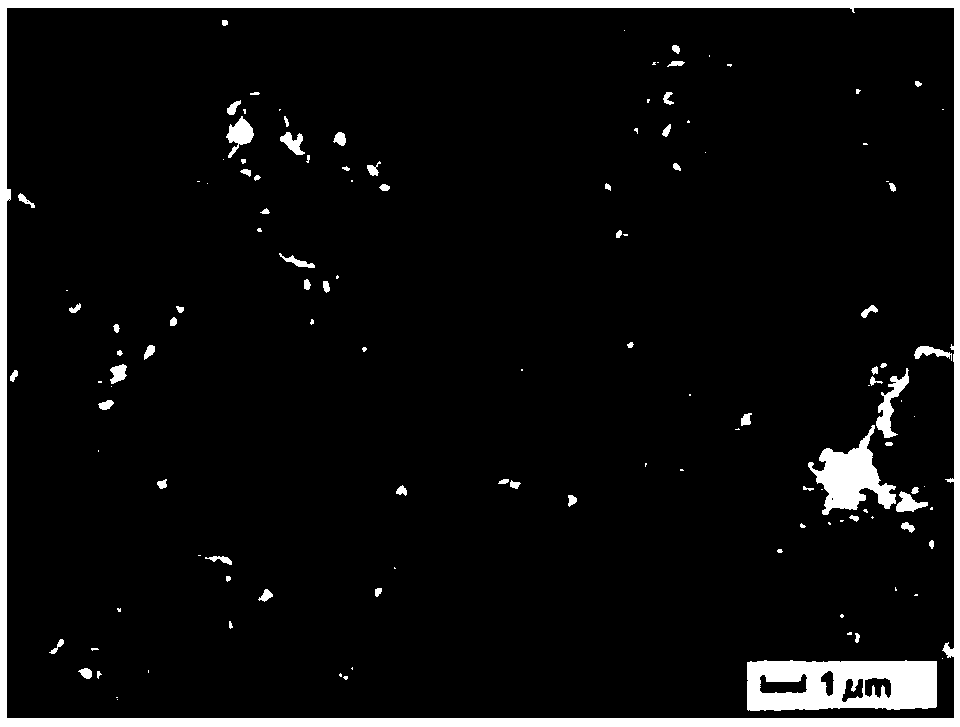

[0032] Step 2, the step of preparing Ag / GCN / carbon sphere (Ag / GCN / C) ternary photoelectric active material:

[0033] First weigh 0.01g GCN and ultrasonically disperse it in 50mL water to obtain solution A, then weigh 0.001g AgNO 3 Dissolved in solution A to obtain solution B. Add solution B, and quickly add 0.001 g of ascorbic acid after solution B boils, keep stirring, and the reaction time is 8 hours to obtain Ag / GCN / C.

[0034] Step 3, constructing a photoelectrochemical sensor for sensitive non-labeled detection of 4-chlorophenol;

[0035] In step 3, prepare...

Embodiment 2

[0038] Step 1, the step of preparing graphite phase carbon nitride (GCN):

[0039] First weigh 1.7g of cyanuric chloride and 40mL of acetonitrile and mix them evenly, then slowly transfer 0.5g of melamine into it, and after it is completely dissolved, transfer the resulting solution to an autoclave for solvent heat treatment, and place the autoclave at 200°C. After reacting for 48h, the solid product obtained was GCN.

[0040] Step 2, the step of preparing Ag / GCN / carbon sphere (Ag / GCN / C) ternary photoelectric active material:

[0041] First weigh 0.04g GCN and ultrasonically disperse it in 50mL water to obtain solution A, then weigh 0.007g AgNO 3 Dissolved in solution A to obtain solution B. Add solution B, and quickly add 0.005 g of ascorbic acid after solution B boils, keep stirring, and the reaction time is 12 hours to obtain Ag / GCN / C.

[0042] Step 3, constructing a photoelectrochemical sensor for sensitive non-labeled detection of 4-chlorophenol;

[0043] In step 3, p...

Embodiment 3

[0046] Step 1, the step of preparing graphite phase carbon nitride (GCN):

[0047]First weigh 0.9g of cyanuric chloride and 20mL of acetonitrile and mix them evenly, then slowly transfer 0.3g of melamine into it, and after it is completely dissolved, transfer the resulting solution to an autoclave for solvent heat treatment, and place the autoclave at 160°C. After reacting for 48h, the solid product obtained was GCN.

[0048] Step 2, the step of preparing Ag / GCN / carbon sphere (Ag / GCN / C) ternary photoelectric active material:

[0049] First weigh 0.02g GCN and ultrasonically disperse it in 50mL water to obtain solution A, then weigh 0.0035g AgNO 3 Dissolved in solution A to obtain solution B. Add solution B, and quickly add 0.0025 g of ascorbic acid after solution B boils, continue stirring, and the reaction time is 12 hours to obtain Ag / GCN / C.

[0050] Step 3, constructing a photoelectrochemical sensor for sensitive non-labeled detection of 4-chlorophenol;

[0051] In step...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com