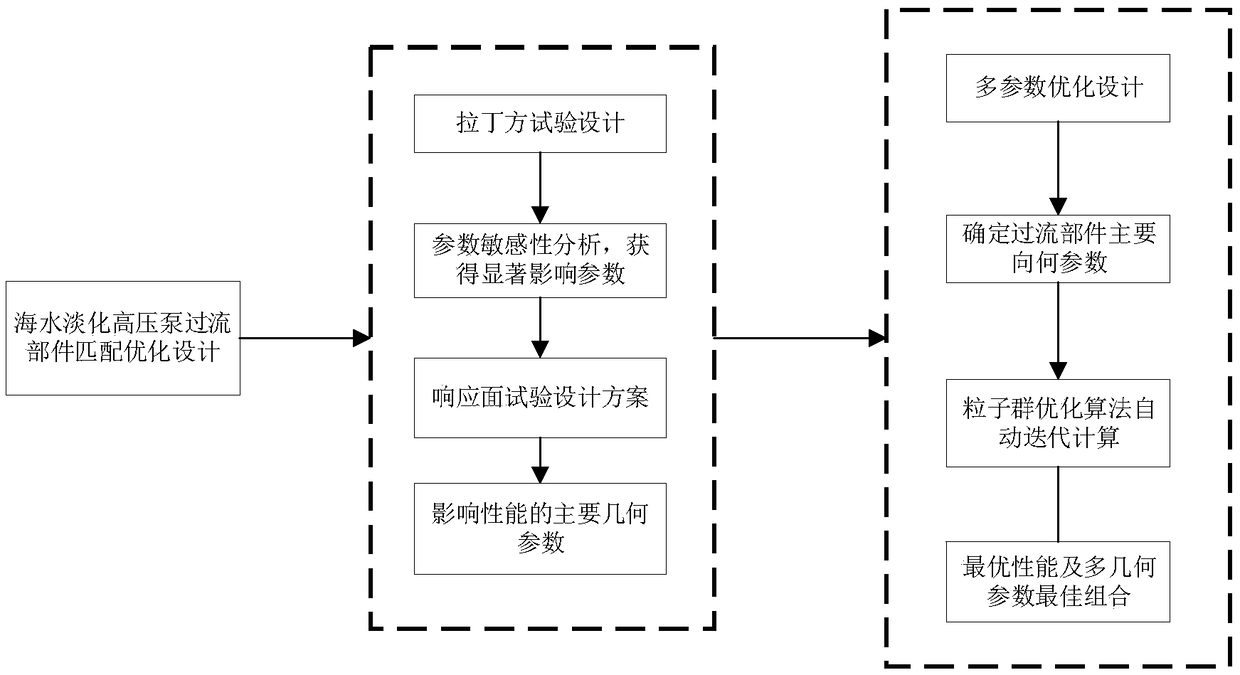

A method for optimizing the matching of the flow component of a high-pressure seawater desalination pump

A technology for flow-passing components and optimized design, applied in computing, special data processing applications, instruments, etc., can solve problems such as large flow loss, high energy consumption in operation, expensive pump equipment, etc., and achieve optimal matching, optimal parameters, etc. Optimum, optimal pump efficiency results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

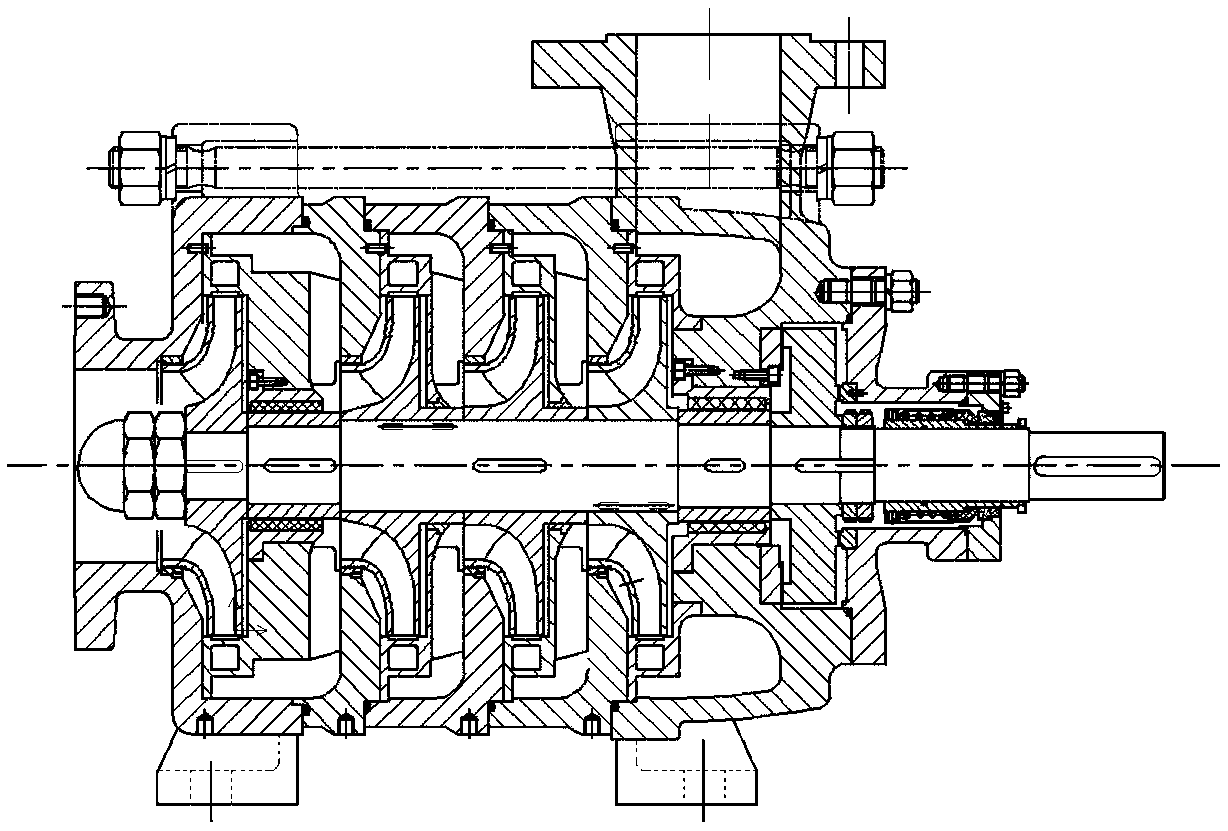

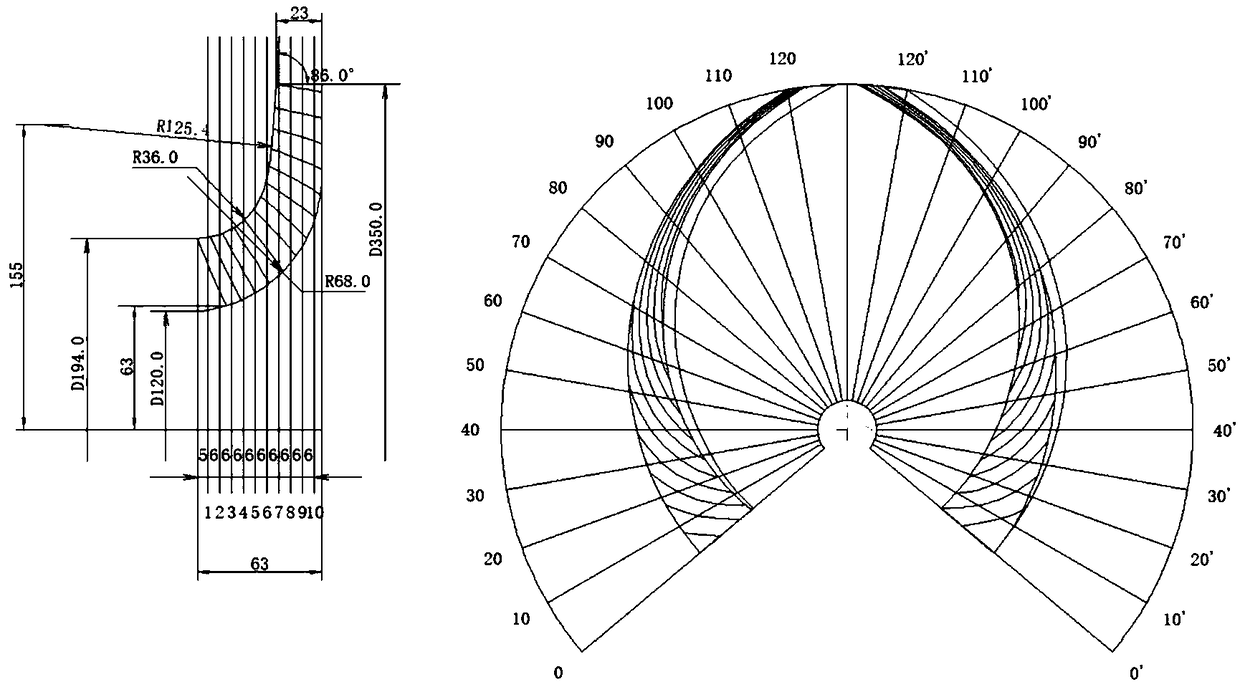

[0014] Embodiment: This article takes the improvement of a 4-stage seawater desalination high-pressure pump as an example. The specific design parameters are: according to the design working condition of the centrifugal pump Q=450m 3 / h, H=600m, speed n=2980r / min; the initial parameters of centrifugal pump impeller, guide vane and anti-guide vane are: impeller inlet diameter D j =194mm, impeller hub diameter D h =120mm, impeller outlet diameter D 2 =350mm, blade outlet width b 2 =23mm, blade inlet placement angle β 1 =35°, blade outlet placement angle β 2 =31°, blade wrap angle Number of impeller blades z b =7; guide vane inlet diameter D 3 =352mm, guide vane inlet angle α 1 =11.2°, the circumferential width of the guide vane inlet b 3 =29mm, axial width of guide vane inlet a 3 =29mm, the circumferential width of the guide vane outlet b 4 =39mm, the axial width of the guide vane outlet a 4 =39mm, guide vane outlet diameter D 4 =480mm, number of guide vane blade...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com