Image transfer sheet, manufacturing method for image transfer sheet, and image transfer method

A transfer sheet and image technology, applied in the field of image transfer sheets, can solve problems such as difficulty in forming an image layer, insufficient volatilization, and fluctuations in the image layer. The possibility of image layer fluctuations is small, and the production efficiency is improved. The effect of quality improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

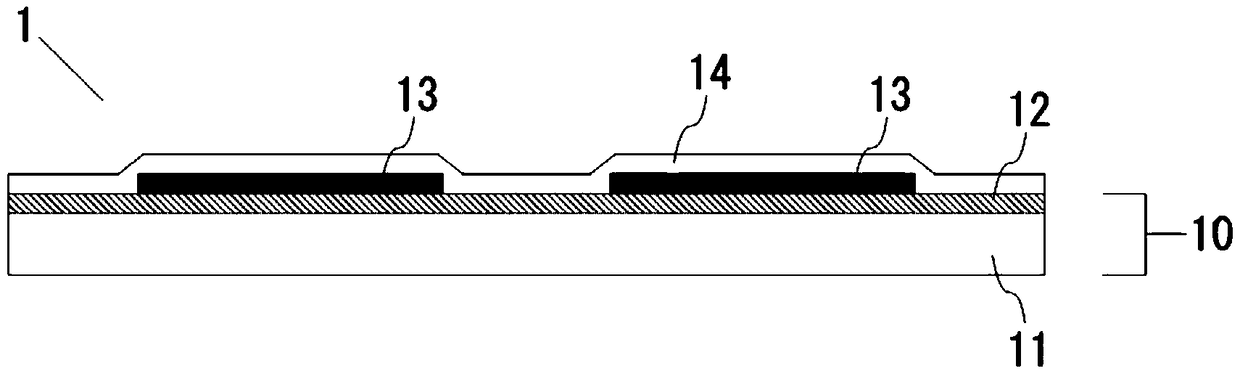

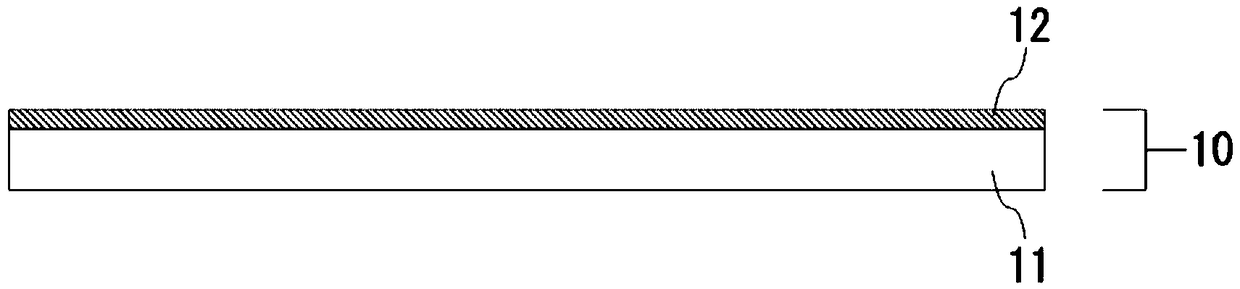

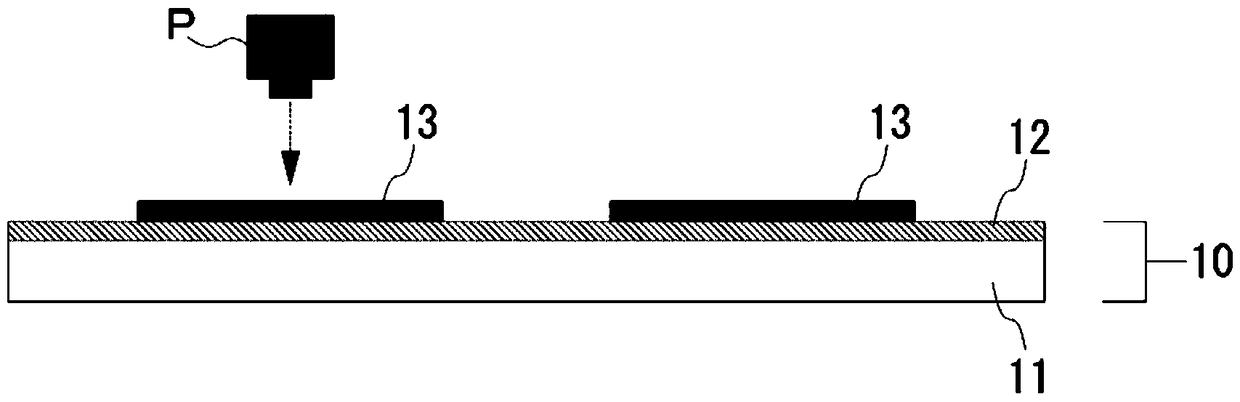

[0060] (first embodiment)

[0061] Next, embodiments of the present invention will be described with reference to the drawings. figure 1 It is a sectional view showing an example of the image transfer sheet 1 according to the embodiment of the present invention. The image transfer sheet 1 has an image layer 13 between the transfer film 14 on the upper layer and the adhesive layer 12 on the lower layer, and the lower surface of the adhesive layer 12 is releasably bonded to the upper surface of the release paper 11 . In this embodiment, the image layer 13 is, for example, UV ink (ink) printed on the upper surface of the adhesive layer 12 by a UV printer, and the photopolymerization reaction is caused by irradiating UV during printing, and it is dried and cured into a thin film.

[0062] The material of the transfer film 14 will be described later. When the adhesive component of the adhesive layer 12 is an acrylic adhesive, a transparent acrylic resin is suitable. The adhesive ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com