High frequency heating device

A high-frequency heating device and frequency technology, applied in the direction of electric heating device, microwave heating, electric heating fuel, etc., to achieve the effect of uniform heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

[0026]

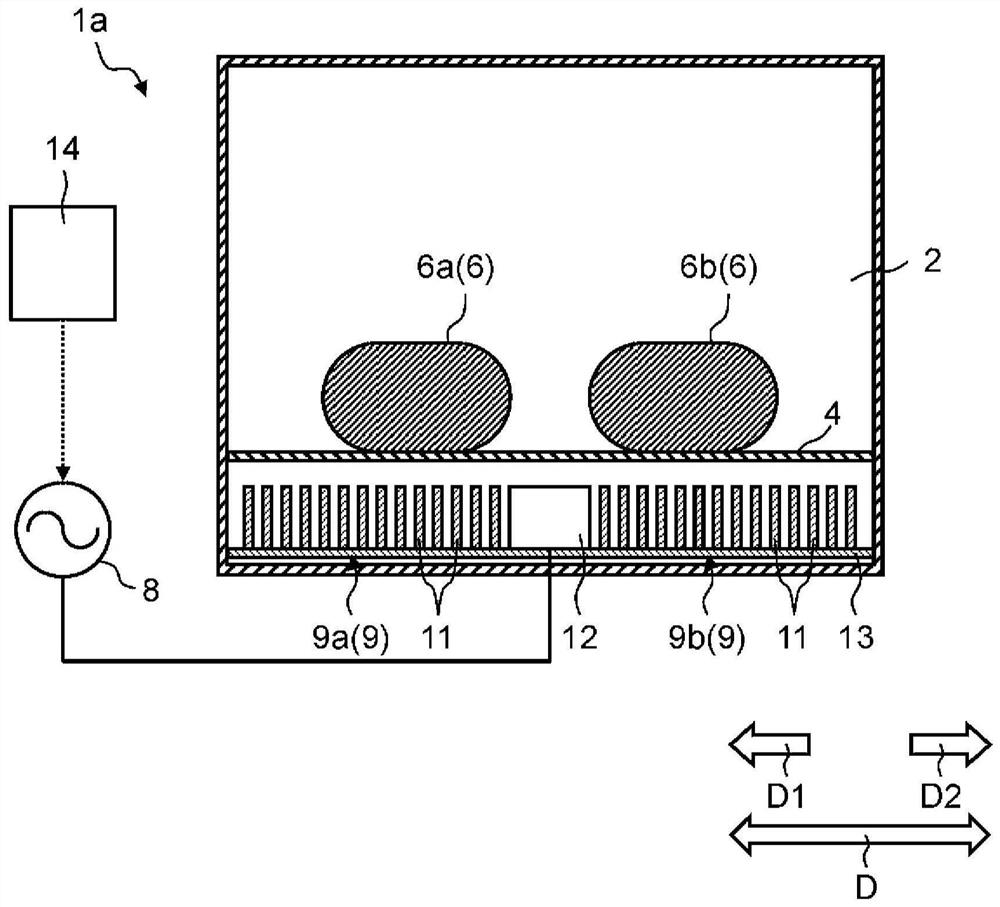

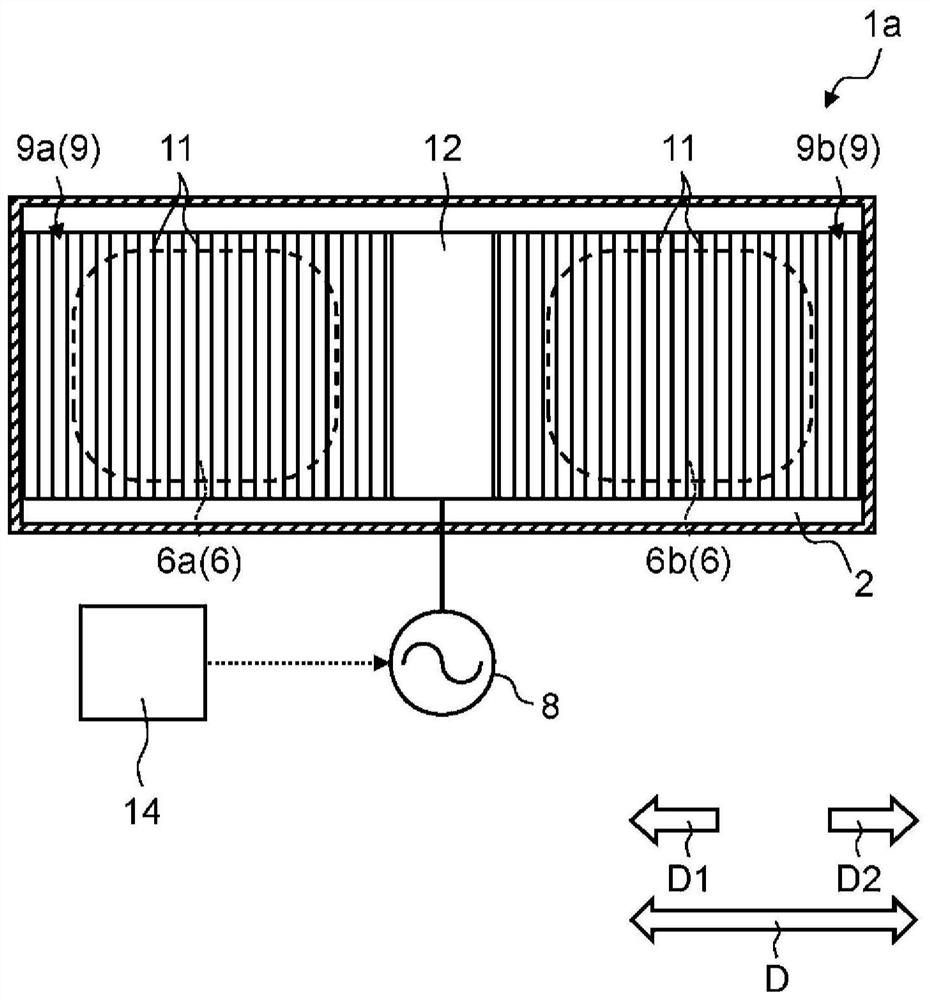

[0027] figure 1 , figure 2 It is a vertical cross-sectional view and a horizontal cross-sectional view schematically showing the structure of the high-frequency heating device 1 a according to Embodiment 1 of the present invention, respectively.

[0028] Such as figure 1 , figure 2 As shown, the high-frequency heating device 1 a has a heating chamber 2 , a generating unit 8 , a surface wave exciter 9 , a coupling unit 12 , and a control unit 14 . The surface wave exciter 9 includes a coupling portion 12 provided in the middle, and a surface wave exciter 9 a and a surface wave exciter 9 b provided to sandwich the coupling portion 12 .

[0029] The high-frequency heating device 1a is configured to heat the object to be heated 6 (in this embodiment, the objects to be heated 6a and 6b ) placed on the mounting table 4 using microwaves propagating on the surface of the surface wave exciter 9 in the surface wave mode. ) for heating.

[0030] Each component will be d...

Embodiment approach 2

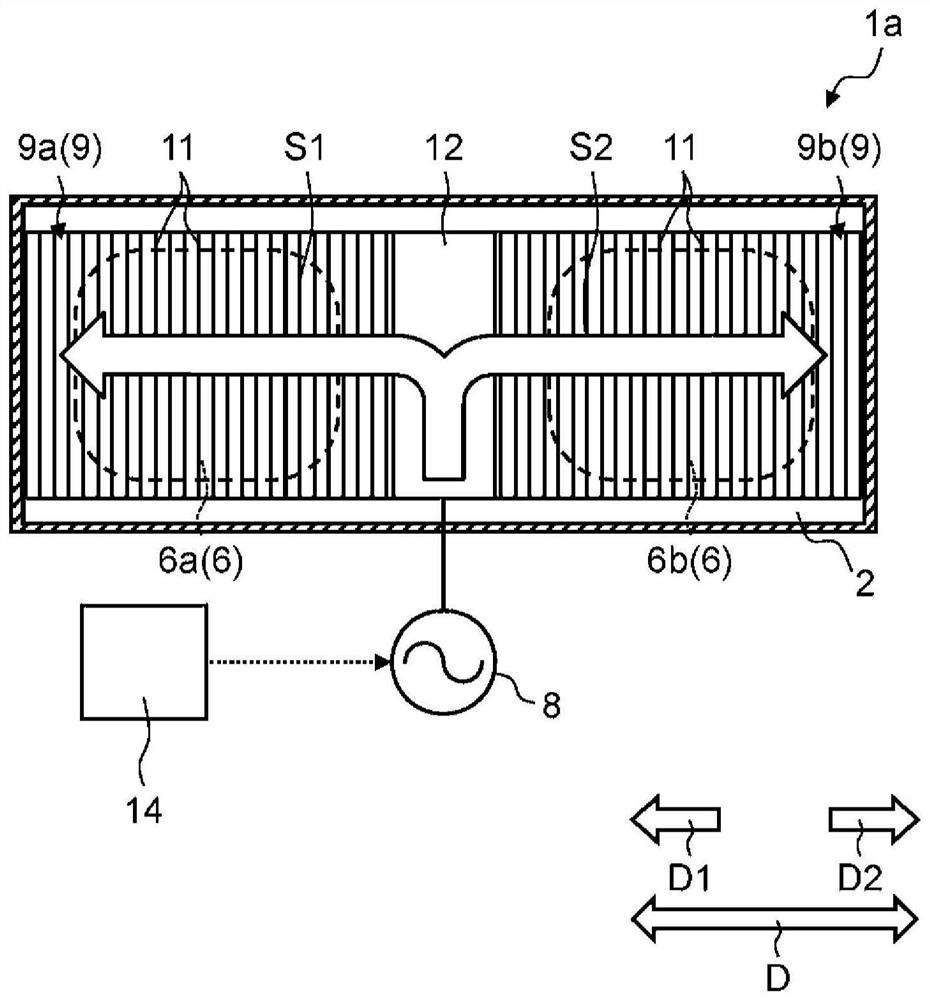

[0056] Regarding the high-frequency heating device 1b according to Embodiment 2 of the present invention, the differences from Embodiment 1 will be mainly described. Figure 4 It is a cross-sectional view schematically showing the structure of the high-frequency heating device 1b. Figure 4 Schematically shows the situation in which microwaves in the surface wave mode propagate on the surface wave excitation body 9, and the heating target object 6 is placed on the mounting table 4 (in the Figure 4 not shown in the figure).

[0057] Such as Figure 4 As shown, the high-frequency heating device 1 b has coupling parts 22 , 24 and a distributor 26 in addition to the configuration of the first embodiment.

[0058] Coupling sections 22 and 24 are respectively provided at both ends of surface wave exciter 9 in microwave propagation direction D so as to supply microwaves generated by generating section 8 to surface wave exciter 9 . In this embodiment, the coupling parts 22 and 24 ...

Embodiment approach 3

[0065] Only the difference from Embodiment 2 will be described about the high-frequency heating device 1c according to Embodiment 3 of the present invention. Figure 5 It is a cross-sectional view schematically showing the structure of the high-frequency heating device 1c. Figure 5 Schematically shows the situation in which microwaves in the surface wave mode propagate on the surface wave excitation body 9, and the heating target object 6 is placed on the mounting table 4 (in the Figure 5 not shown in the figure).

[0066] Such as Figure 5 As shown, the high-frequency heating device 1 c further includes a generating unit 32 and a generating unit 34 . The high-frequency heating device 1 c includes a control unit 36 configured to control the production units 8 , 32 , and 34 instead of the control unit 14 .

[0067] The high-frequency heating device 1c does not have the distributor 26 but has the coupling parts 22 and 24 respectively connected to the generating part 32 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com