Improved discharging device

A discharge device and an improved technology, applied in the direction of drying solid materials, grain processing, lighting and heating equipment, etc., to reduce the amount of operation, avoid moisture absorption, and increase continuity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

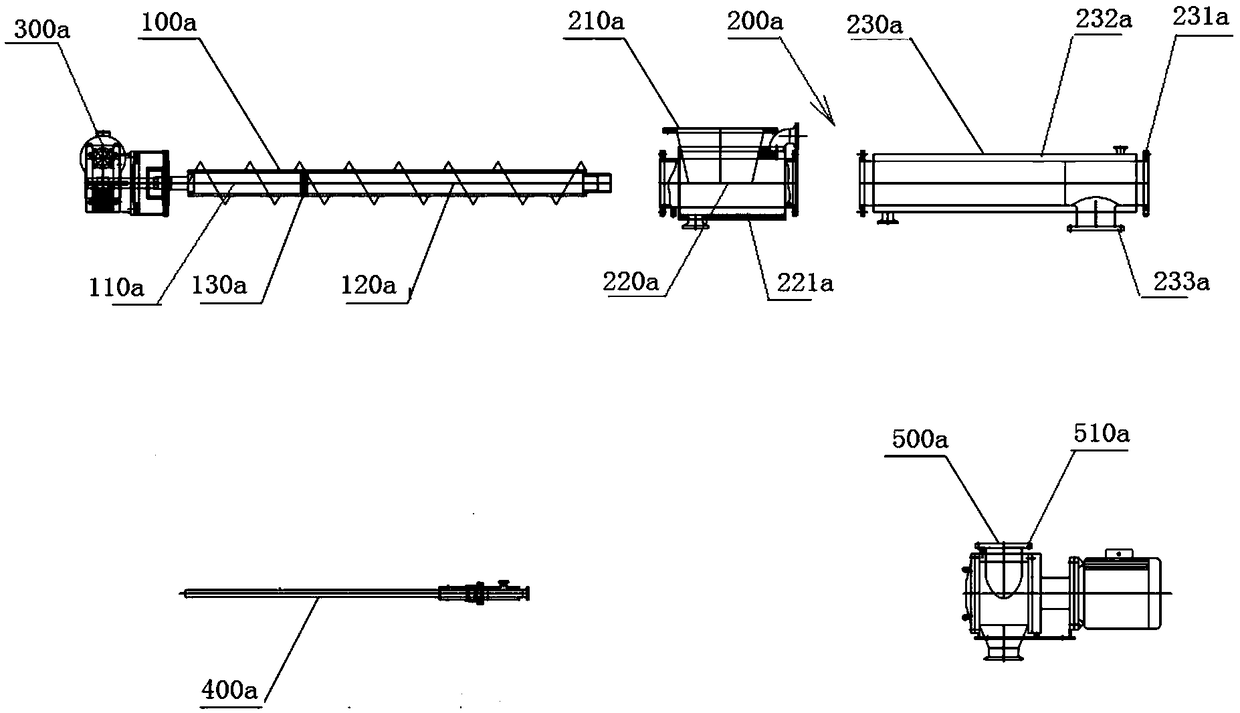

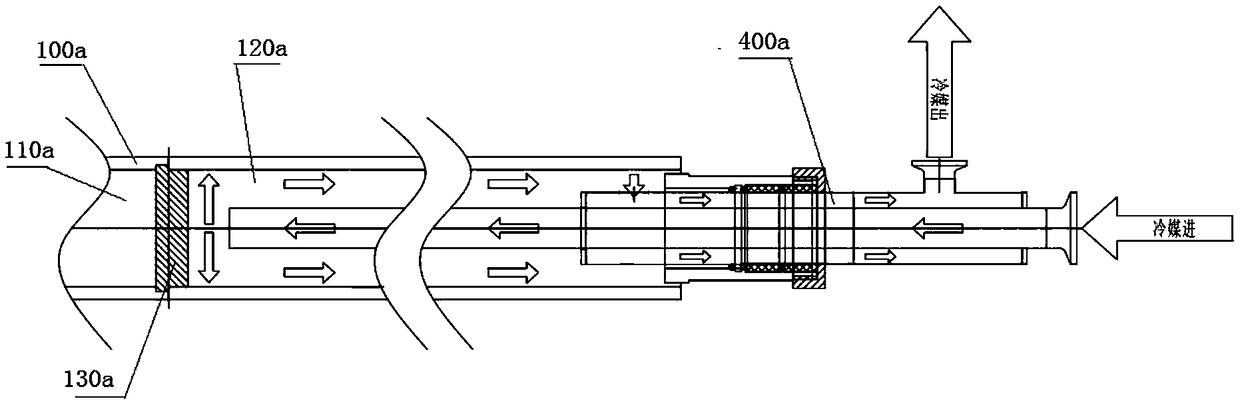

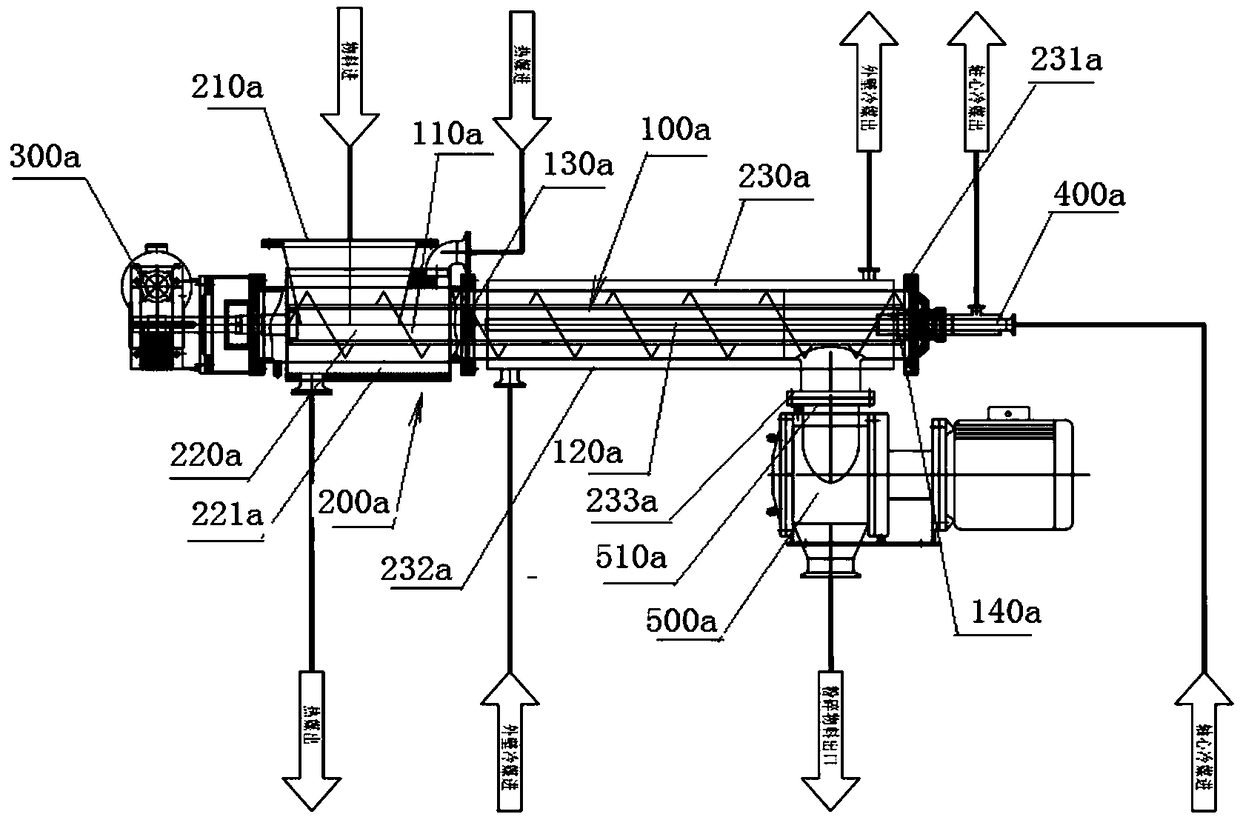

[0037] see figure 1 , figure 2 and image 3 The improved discharge device of this embodiment is an auger conveyor, which has an auger 100a, a feeding cylinder 200a set on the auger 100a, and a twisting auger installed at one end of the auger 200a. The auger driving mechanism 300a, the auger driving mechanism 300a is no different from the auger driving mechanism in the existing auger conveyor, and will not be described in detail here. The auger driving mechanism drives the auger to rotate for feeding. A feeding port 210a is provided at one end of the feeding barrel 200a close to the auger driving mechanism 300a, and the feeding port 210a communicates with the inside of the feeding barrel 200a.

[0038] The feeding tube 200a of this embodiment is divided into two sections, that is, a first section feeding tube 220a and a second section feeding tube 230a, and one end of the second section feeding tube 230a is away from the first section feeding tube 220a. The end of the auge...

Embodiment 2

[0052] see Figure 4 and Figure 5 , the improved discharge device of this embodiment is an auger conveyor, which has an auger 100 and a feeding tube 200 set on the auger 100 and an auger driving mechanism 300 installed at one end of the auger 200 , the auger driving mechanism 300 is no different from the auger driving mechanism in the existing auger conveyor, and will not be described in detail here. The auger driving mechanism 300 drives the auger 100 to rotate for feeding. An end of the feeding barrel 200 close to the auger driving mechanism 300 is provided with a feeding port 210 , and the feeding port 210 communicates with the inside of the feeding barrel 200 .

[0053] The feeding tube 200 of this embodiment is divided into two sections, that is, the first section feeding tube 220 and the second section feeding tube 230, and the second section feeding tube 231 is connected with the first section feeding tube 220 The end 221 far away from the auger driving mechanism 30...

Embodiment 3

[0069] see Figure 6 and Figure 7 , the difference between the improved discharge device shown in the figure and the improved discharge device of embodiment 2 is that: the second section auger 120 is replaced by an auger fixing collar 150 with a through shaft 140, and the auger fixing collar 150 is fixed on one end of the through shaft 140, and the outer peripheral surface of the auger fixing collar 150 is level with the outer peripheral surface of the auger 100. The end of the dragon shaft 130 away from the auger driving mechanism 300 can be rotatably connected, and the through shaft 140 can be made into a water jacket, and the inner hole thereof is led into a refrigerant. The hot dry material in the equipment is relatively soft and has good plasticity. After the material enters the second discharge section, due to the existence of the through shaft 140, the material is plasticized into a state similar to a hollow cylinder, which increases the cooling efficiency and facilit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com