Preparation method of non-ionic waterborne epoxy curing agent

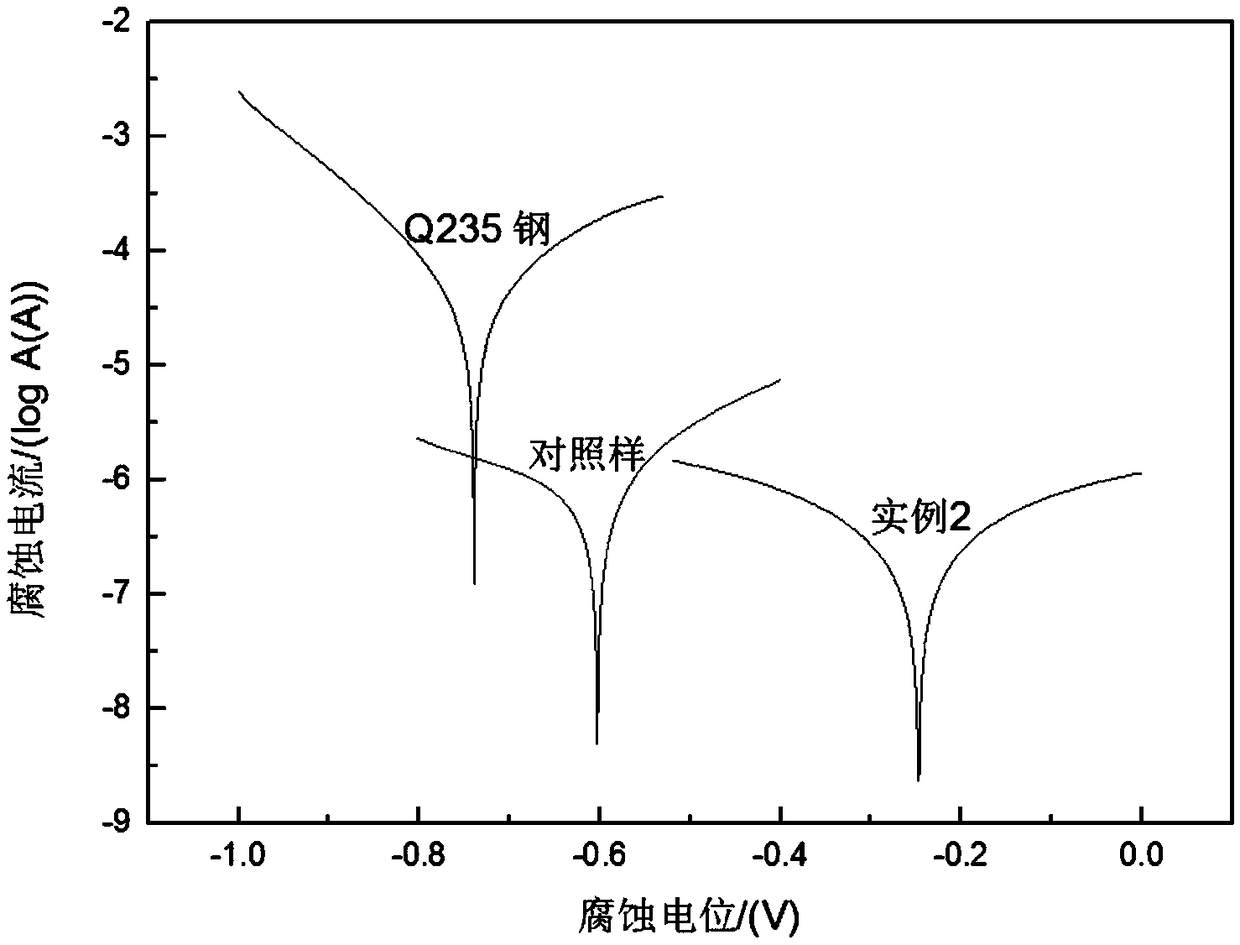

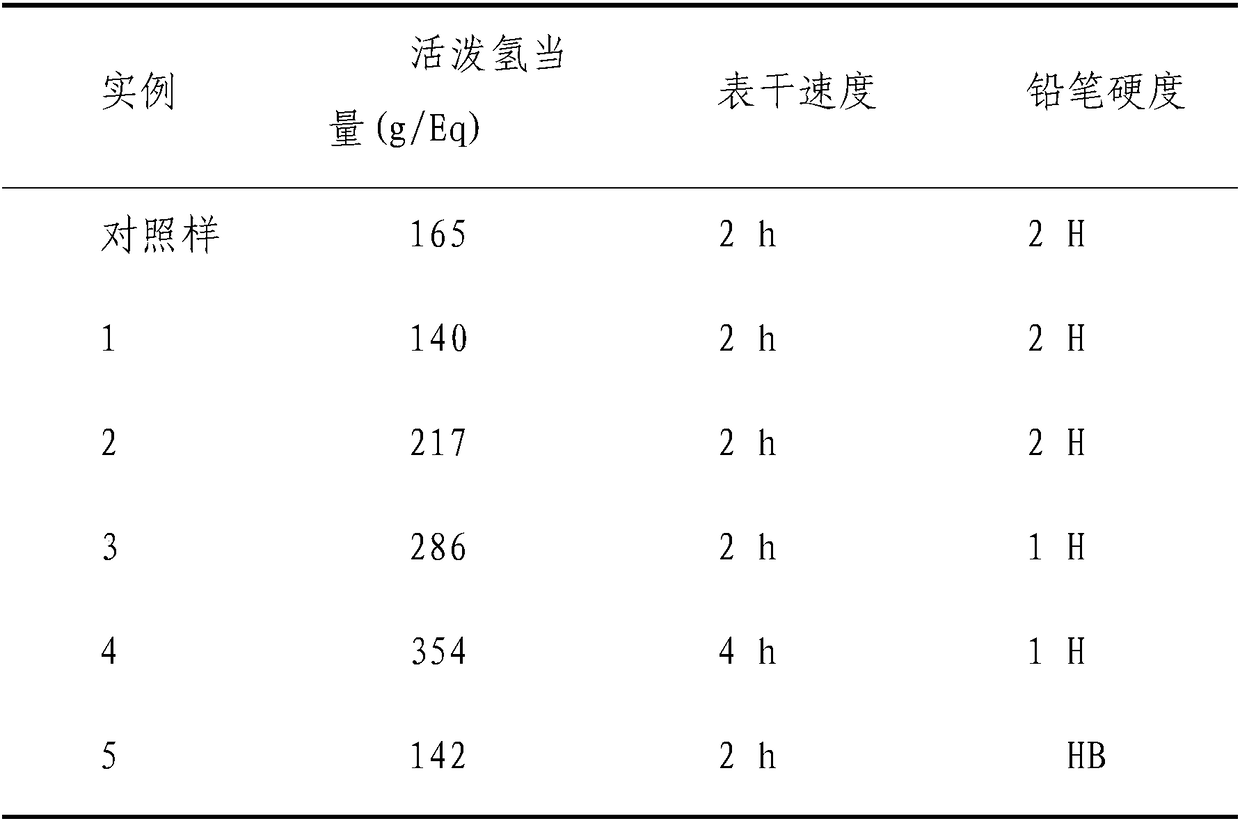

A water-based epoxy, non-ionic technology, applied in the field of fine chemicals, can solve the problems of difficult preparation of non-ionic water-based epoxy curing agent, poor performance of water-based epoxy resin system, etc., achieve excellent application effect, improve metal Anti-corrosion performance, the effect of improving the anti-corrosion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] A preparation method of nonionic water-based epoxy curing agent, the steps are as follows:

[0023] (1) Preparation of amino-terminated prepolymer: Add 21.9g of triethylenetetramine into the reactor, stir and heat to 70°C, then drop 18.5g of epoxy resin E-54 into the reactor within 2 hours Reaction, after the dropwise addition is completed, keep warm for 1 hour to obtain an amino-terminated prepolymer;

[0024] (2) Preparation of aldehyde group capping agent: mix 30g of styrene phenol polyoxyethylene ether (10) with 0.15g of PdCl 2 -CuCl 2 Mix and heat to 100°C, feed oxygen at a ventilation rate of 0.4mL / g min, and react for 4 hours to prepare benzaldehyde phenol polyoxyethylene ether;

[0025] (3) Capping reaction: Mix and heat the products of the above two steps to 85°C, react for 2 hours, then cool to 60°C, slowly add 47g of water, cool to room temperature after adding water, and obtain a clear viscous liquid, obtained Non-ionic water-based epoxy curing agent.

Embodiment 2

[0027] A preparation method of nonionic water-based epoxy curing agent, the steps are as follows:

[0028] (1) Preparation of amino-terminated prepolymer: Add 29.2g of triethylenetetramine into the reactor, stir and heat to 70°C, then add 19.6g of epoxy resin E-51 dropwise into the reactor within 2 hours Reaction, after the dropwise addition is completed, keep warm for 1 hour to obtain an amino-terminated prepolymer;

[0029] (2) Preparation of aldehyde group capping agent: mix 60g of styrene phenol polyoxyethylene ether (10) with 0.3g of PdCl 2 -CuCl 2 Mix and heat to 100°C, feed oxygen at a ventilation rate of 0.5mL / g min, and react for 4 hours to prepare benzaldehyde phenol polyoxyethylene ether;

[0030] (3) Capping reaction: Mix and heat the products of the above two steps to 85°C, react for 2 hours, then cool to 60°C, slowly add 80.5g of water, cool to room temperature after adding water, and obtain a clear viscous liquid. Obtain non-ionic water-based epoxy curing age...

Embodiment 3

[0032] A preparation method of nonionic water-based epoxy curing agent, the steps are as follows:

[0033] (1) Preparation of amino-terminated prepolymer: Add 20.6g of diethylenetriamine into the reactor, stir and heat to 70°C, then drop 22.7g of epoxy resin E-44 into the reactor within 3 hours Reaction, after the dropwise addition is completed, keep warm for 1 hour to obtain an amino-terminated prepolymer;

[0034] (2) Preparation of aldehyde-blocking agent: mix 100g of styrene phenol polyoxyethylene ether (20) with 0.5g of PdCl 2 -CuCl 2 Mix and heat to 100°C, feed oxygen at a ventilation rate of 0.5mL / g min, and react for 4 hours to prepare benzaldehyde phenol polyoxyethylene ether;

[0035] (3) Capping reaction: Mix and heat the products of the above two steps to 85°C, react for 3 hours, then cool to 60°C, slowly add 95.5g of water, cool to room temperature after adding water, and obtain a clear viscous liquid. Obtain non-ionic water-based epoxy curing agent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com