Marine heavy-duty anti-corrosion coating and preparation method thereof

A coating and marine technology, which is applied in the field of marine heavy anti-corrosion coating and its preparation, can solve the problems of incompatibility, unsuitable for industrial production, and the economic benefit needs to be improved, and achieves the effect of facilitating electrical conductivity and improving metal anti-corrosion performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] (1) Preparation of B-N coordination polyaniline / montmorillonite composite conductive material

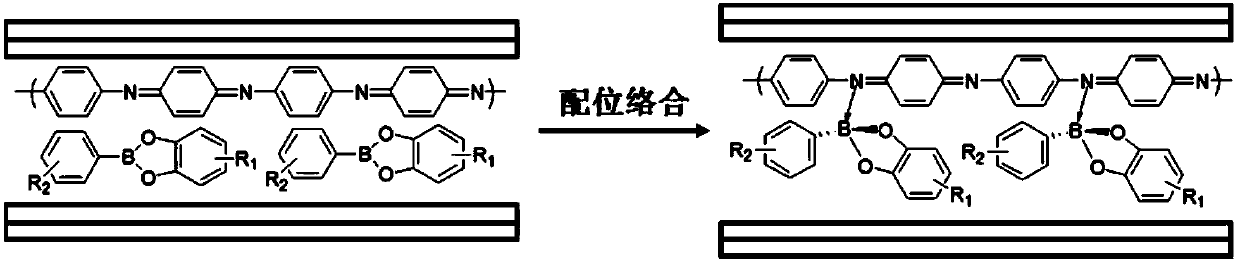

[0052] a. Add 50 parts of CTAB organically modified montmorillonite to 500 parts of 1mol / L organic boric acid solution to disperse, and stir evenly with a mixer at a speed of 800r / min at room temperature to form a suspension system, and continue stirring for 5h. Add 10 parts of aniline monomer to the suspension to carry out aniline intercalation reaction in situ, and continue to stir for 6 hours to fully intercalate. The coordination process of this step is as follows: figure 1 shown;

[0053] b. At room temperature, add an oxidant with the same molar amount as the aniline monomer and 10 parts of bishydroxyphenol derivatives into the aniline emulsion, and react for 8 hours under nitrogen protection;

[0054] c. After the reaction is completed, ultrasonically disperse in water first, and then perform centrifugation. The obtained precipitate is repeatedly washed with deionized...

Embodiment 2

[0058] (1) Preparation of B-N coordination polyaniline / montmorillonite composite conductive material

[0059] a. Add 50 parts of CTAB organically modified montmorillonite to 500 parts of 1mol / L organic boric acid solution to disperse, and stir evenly with a mixer at a speed of 700r / min at room temperature to form a suspension system, and continue stirring for 5h. Add 12 parts of aniline monomer to the suspension for aniline in-situ intercalation reaction, and continue stirring for 6 hours to fully intercalate;

[0060] b. At room temperature, add an oxidant with the same molar amount as the aniline monomer and 15 parts of bishydroxyphenol derivatives into the aniline emulsion, and react for 8 hours under nitrogen protection;

[0061] c. After the reaction is completed, ultrasonically disperse in water first, and then perform centrifugation. The obtained precipitate is repeatedly washed with deionized water and acetone until the filtrate is neutral, and the obtained precipitate...

Embodiment 3

[0065] (1) Preparation of B-N coordination polyaniline / montmorillonite composite conductive material

[0066] a. Add 50 parts of CTAB organically modified montmorillonite to 500 parts of 1mol / L organic boric acid solution to disperse, and stir evenly with a mixer at a speed of 1000r / min at room temperature to form a suspension system, and continue stirring for 5h. Add 15 parts of aniline monomer to the suspension for aniline in-situ intercalation reaction, and continue to stir for 6 hours to fully intercalate;

[0067] b. At room temperature, add an oxidant with the same molar amount as the aniline monomer and 5 parts of bishydroxyphenol derivatives into the aniline emulsion, and react for 8 hours under nitrogen protection;

[0068] c. After the reaction is completed, ultrasonically disperse in water first, and then perform centrifugation. The obtained precipitate is repeatedly washed with deionized water and acetone until the filtrate is neutral, and the obtained precipitate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com