A high transmittance photovoltaic encapsulation material using nucleating antireflection agent

A packaging material, high light transmittance technology, applied in photovoltaic power generation, adhesives, adhesive additives, etc., can solve the long-term UV resistance and mechanical properties of EVA film, the high price of graphene oxide nanometer, affects the long-term reliability of components to improve the photoelectric conversion efficiency, shorten the molding cycle, and increase the strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

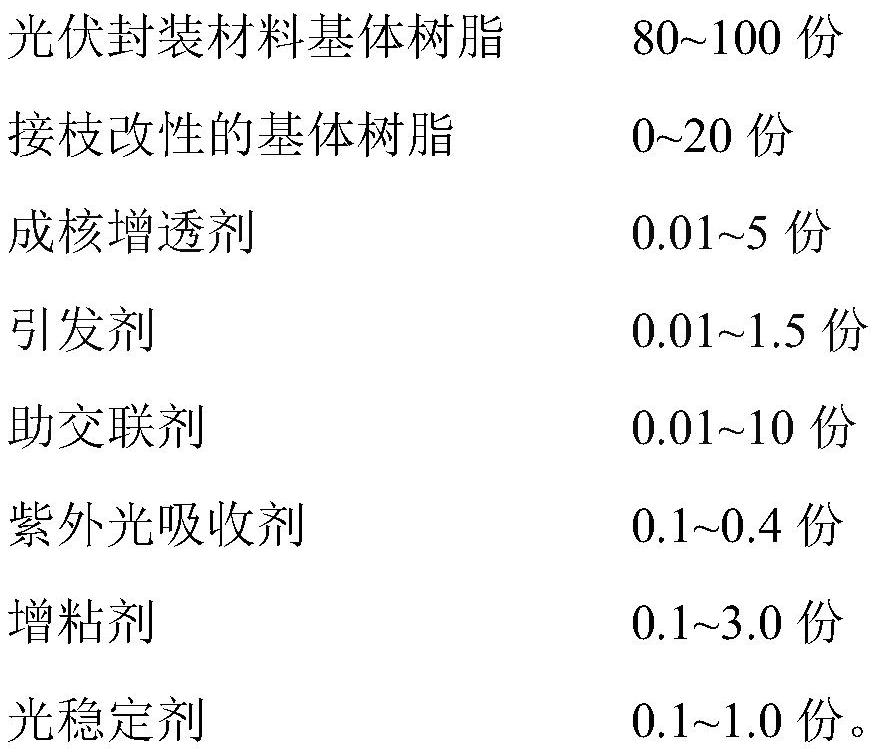

[0023] This embodiment provides a photovoltaic encapsulation material with high light transmittance.

[0024] In this example, by mass fraction, the VA mass content of 100 mass parts is the ethylene-vinyl acetate copolymer of 28%, adds the cadmium sulfide of 0.5 mass part, the tert-butyl peroxyisopropyl carbonate of 1 mass part, 5 parts by mass of trimethylolpropane triacrylate, 1 part by mass of KH550, 0.1 part by mass of 2-hydroxy-4-n-octyloxybenzophenone, 0.1 part by mass of bis-2,2,6 sebacic acid ,6-tetramethylpiperidinol ester. Mix evenly, and the above mixture is pre-mixed, melt-extruded, cast into a film, cooled, slitting and winding to obtain the photovoltaic encapsulation material, which is denoted as E-1.

Embodiment 2

[0026] This embodiment provides a photovoltaic encapsulation material with high light transmittance.

[0027] In this example, in terms of mass fractions, 90 parts by mass of ethylene-vinyl acetate copolymer with a mass content of VA of 26% is added, and 10 parts by mass of the above-mentioned ethylene-vinyl acetate copolymer (with a mass content of VA of 26%) and Cadmium selenide blended and granulated masterbatch at 5 wt%, 1 mass part of tert-butyl peroxyisopropyl carbonate, 5 mass parts of trimethylolpropane triacrylate, 2 mass parts of KH550, 0.4 mass parts 2-Hydroxy-4-n-octyloxybenzophenone, 1 part by mass of bis-2,2,6,6-tetramethylpiperidinol sebacate. Mix evenly, and the above mixture is pre-mixed, melt-extruded, cast into a film, cooled, slitting and winding to obtain the photovoltaic packaging material, which is designated as E-2.

Embodiment 3

[0029] This embodiment provides a photovoltaic encapsulation material with high light transmittance.

[0030]In this example, in terms of mass fractions, 90 parts by mass of ethylene-vinyl acetate copolymer with a mass content of VA of 20%, 10 parts by mass of ethylene-vinyl acetate copolymer with a mass content of 20% are grafted with methyl Acrylic anhydride (graft rate 10%), adding 5 mass parts of zinc sulfide, 1.5 mass parts of tert-butyl peroxide 3,3,5-trimethylhexanoate, 10 mass parts of pentaerythritol triacrylate, 3 mass parts 0.2 parts by mass of KH550, 0.2 parts by mass of 2-hydroxy-4-n-octyloxybenzophenone, and 0.5 parts by mass of bis-2,2,6,6-tetramethylpiperidinol sebacate. Mix evenly, and the above mixture is pre-mixed, melt-extruded, cast into a film, cooled, slitting and winding to obtain the photovoltaic packaging material, which is marked as E-3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com