Mining scraper type electric hydraulic excavator

A hydraulic excavator and scraper type technology, applied in mechanically driven excavators/dredgers, earthmoving machines/shovels, construction, etc., can solve the problems of reducing the safety factor of mine construction, wasting manpower, material and financial resources, etc. The effect of improving work efficiency and work safety, reducing labor intensity and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings.

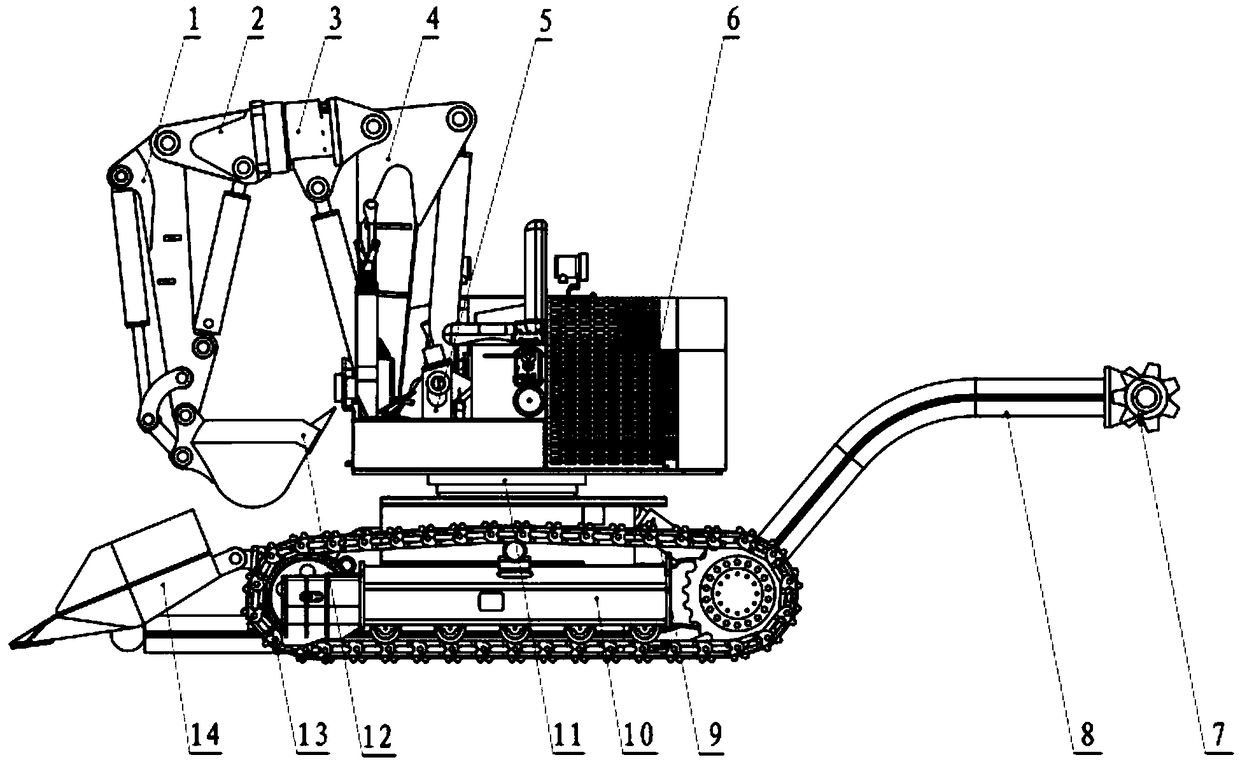

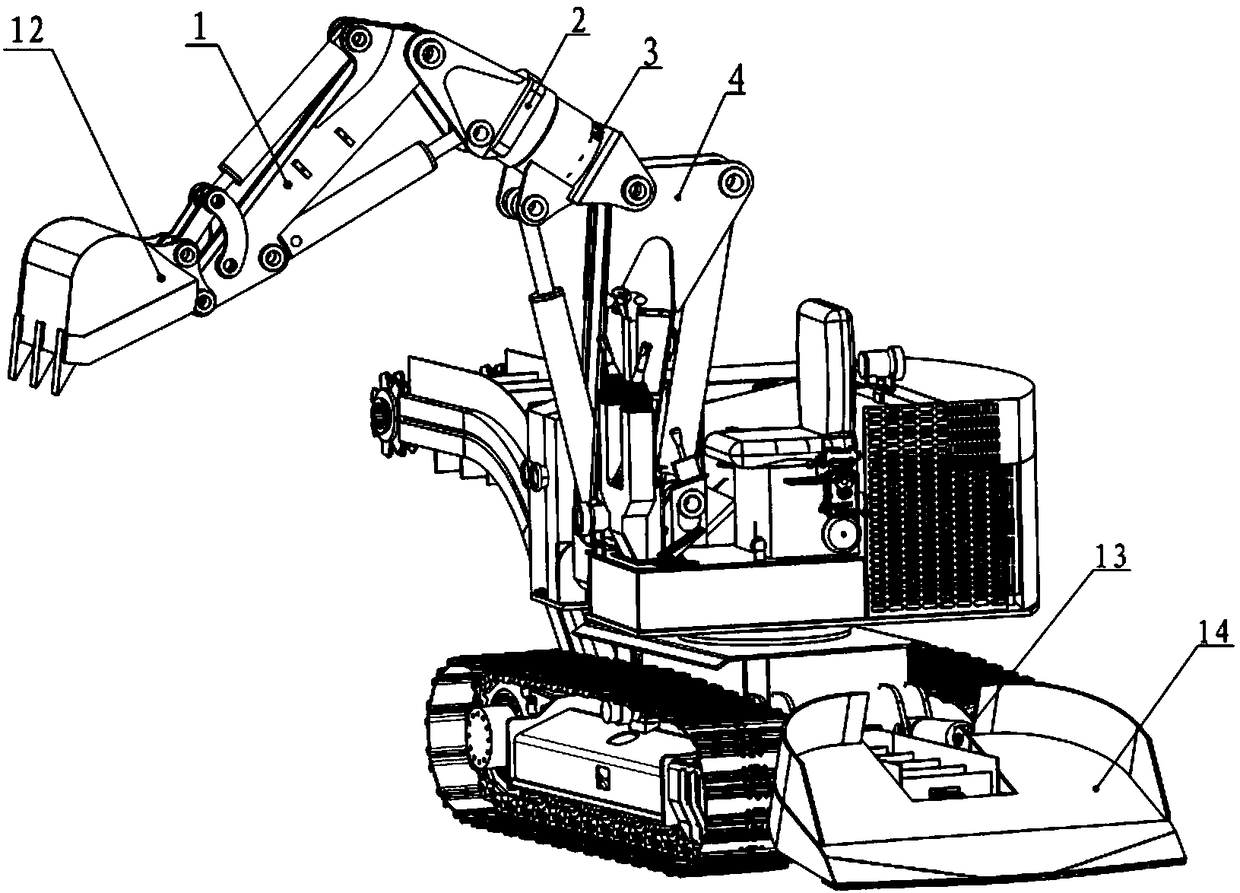

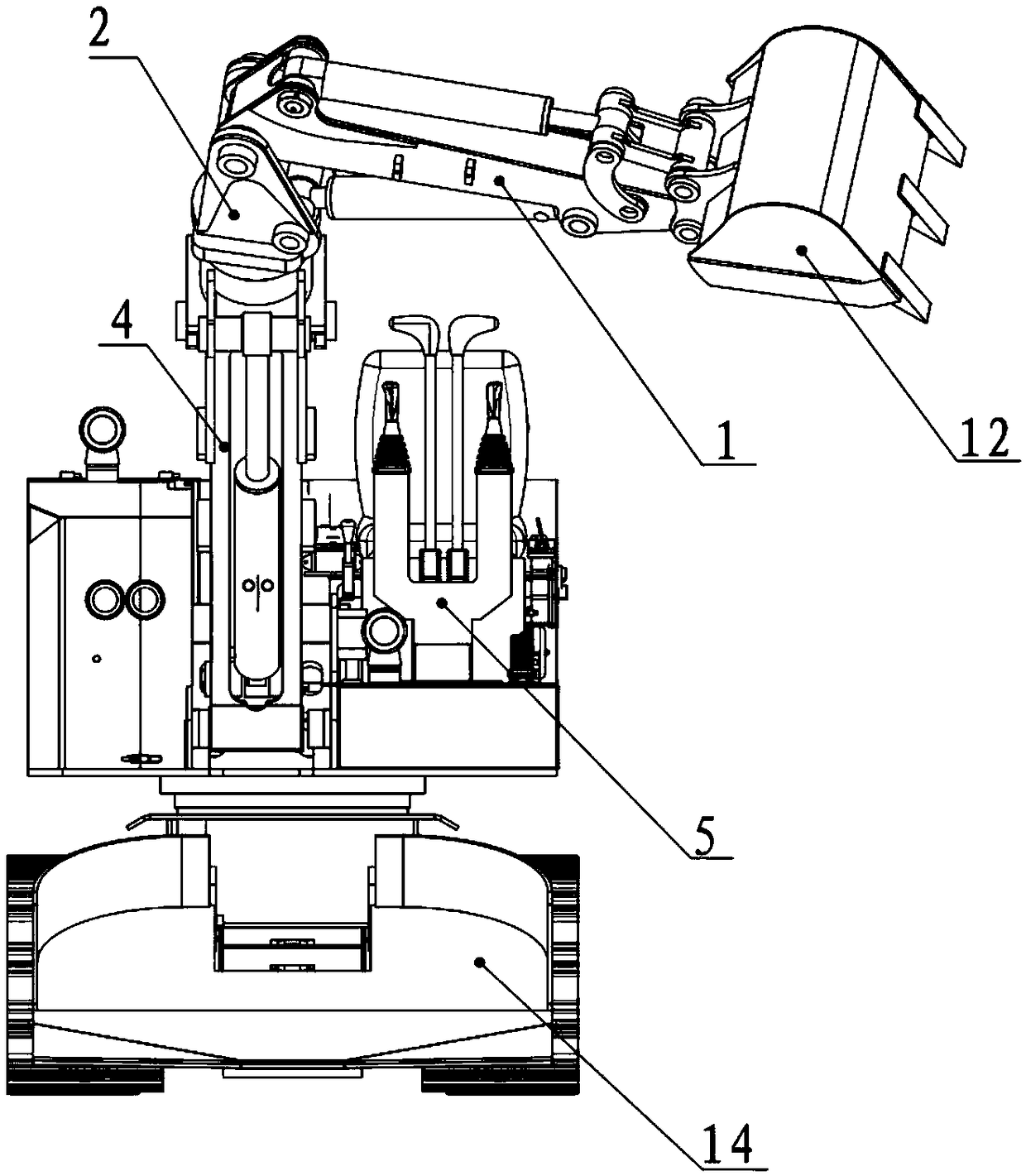

[0025] Such as Figure 1 to Figure 3 As shown, the mining scraper type electric hydraulic excavator includes a boom 4 arranged on the upper frame of the excavator, an auxiliary arm 2 connected with the boom 4, the auxiliary arm 2 has a built-in rotary cylinder 3, and the auxiliary arm 2 The connected forearm 1; the forearm 1 is connected to the bucket 12 through telescopic oil cylinder control. Boom 4, auxiliary arm 2 and forearm 1 constitute the three-section arm working structure of the present invention.

[0026] It also includes a scraper conveying belt 8 that runs through the cavity of the chassis of the excavator, and a bucket 14 is provided at the front end of the scraper conveying belt 8 .

[0027] Further, the boom 4 is connected to the auxiliary arm 2 through a telescopic oil cylinder. The telescopic operation between the auxiliary arm 2 and the boom 4 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com