Total-cross-section fly ash sampling and collecting device and automatic control method

A collection device and a full-section technology, applied in the thermal field of power plants, can solve the problems of less ash falling in the ash hopper, the error between the analysis value and the actual measurement value, and the poor effectiveness of fly ash sample collection, so as to ensure reliability and safety. Faster process, less maintenance and less risk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

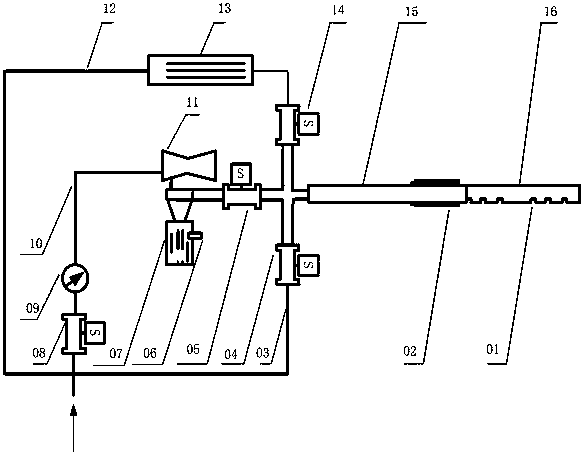

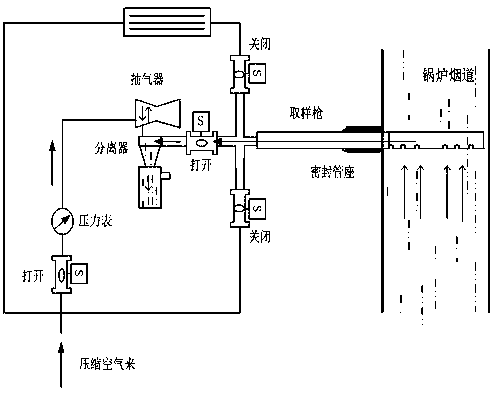

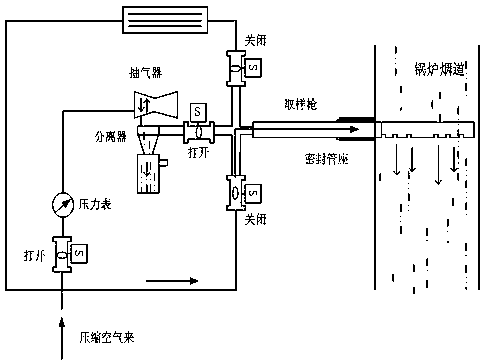

[0032] Such as Figures 1 to 5 Shown is an embodiment of a full-section fly ash sampling collection device and an automatic control method of the present invention. The full-section fly ash sampling collection device includes a fly ash sampling gun 15 for fly ash sampling, a fly ash sampling probe 16, and a fly ash sampling probe 16 for Provide the power source and collect the fly ash suction collection device of fly ash, the blasting first sweeping device and the gradient sweeping second sweeping device, the fly ash sampling probe 16 is connected with the fly ash sampling gun 15 for providing The fly ash pumping and collecting device for extracting the power source, the first blowing device for blasting and the second cleaning device for gradient purge are all connected with the fly ash sampling gun 15 through an independent controller, and the fly ash sampling gun 15 is also equipped with a Sampling hole 01 for sampling.

[0033] Among them, the fly ash extraction and colle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com