Coal ash ultrafine powder grinding system realizing multi-stage circular processing and pre-scattering

A recycling processing and ultra-fine powder technology, which is applied in grain processing and other fields, can solve problems such as poor output, poor dispersion of raw material fly ash, waste of resources, etc., to achieve multi-level recycling, maximize utilization, Effect of preventing flying dust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

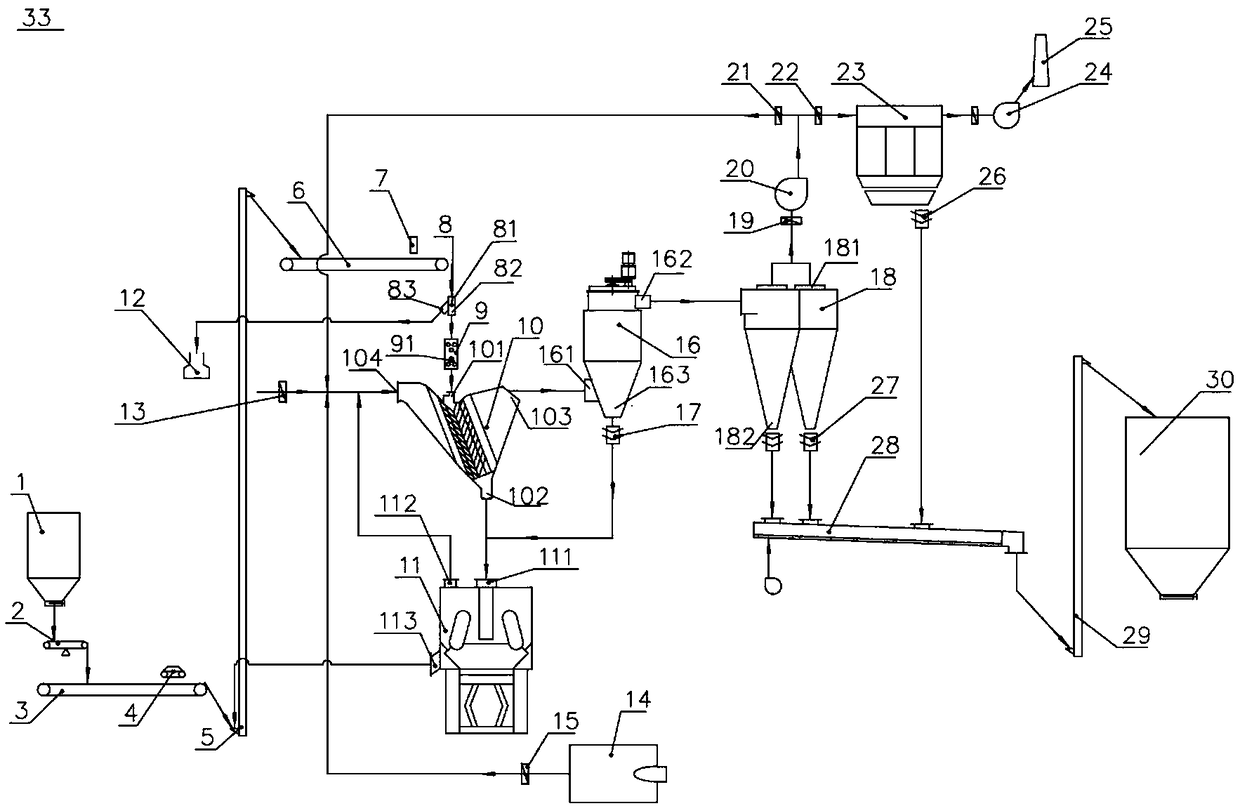

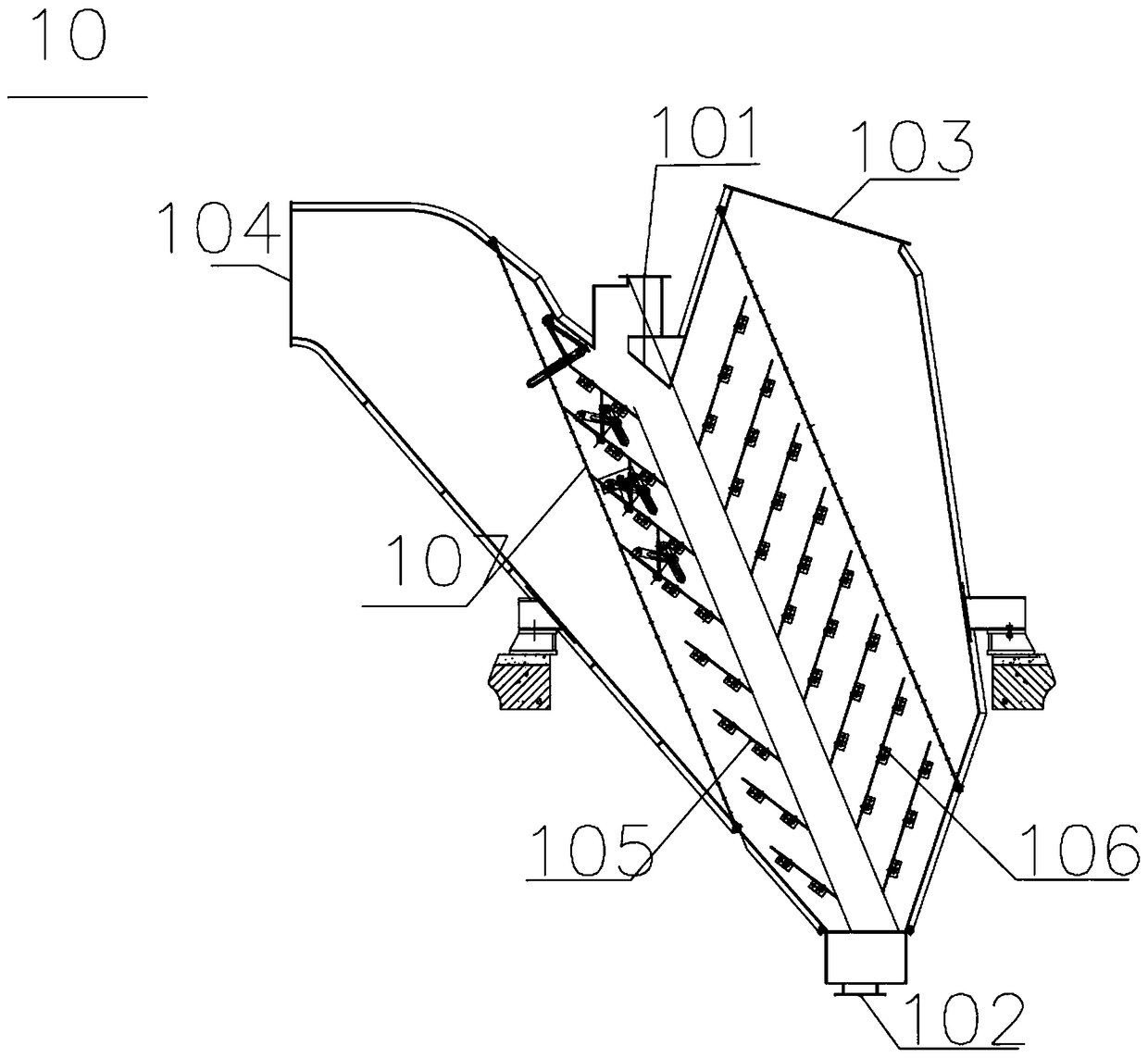

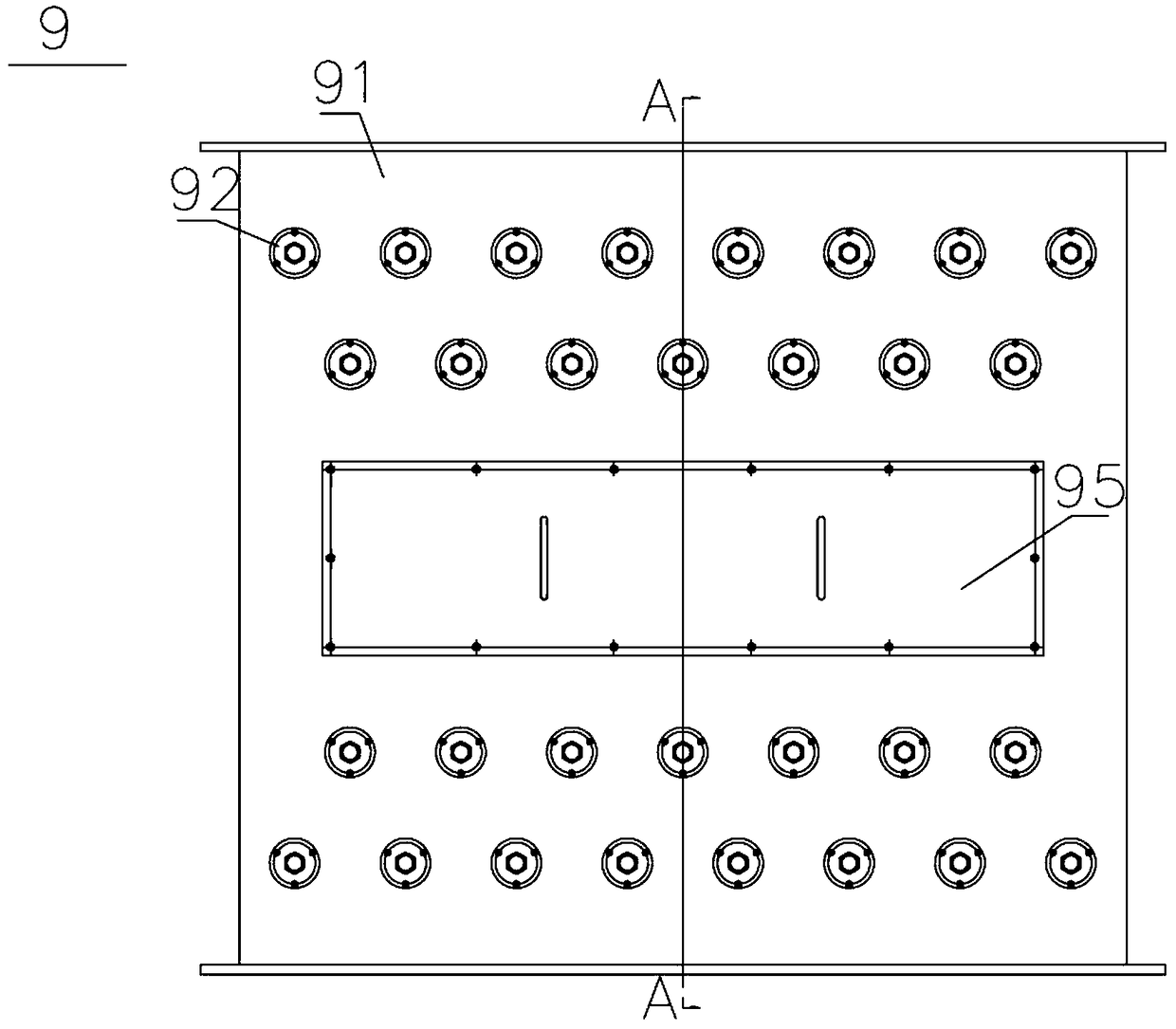

[0028] Such as Figure 1-6 As shown, in an embodiment of the present invention, a multi-stage circulation processing and pre-dispersed fly ash ultra-fine grinding system 33 is disclosed, and the multi-stage circulation processing and pre-dispersion fly ash ultra-fine grinding The system 33 includes a feeding device 32, a first regulating valve 13, a second regulating valve 22, a third regulating valve 19, a fourth regulating valve 21, a pre-dispersing device 9, a V-type coal pulverizer 10, and a vertical roller mill 11. The first air lock valve 17, the second air lock valve 26, the third air lock valve 27, the cyclone powder separator 16, the cyclone separator 18, the dust collector 23, the first fan 20 and the air chute 28 ,in:

[0029] The pre-dispersing device 9 is connected with the feeding device 32, and the feeding device 32 is used to transport the material (fly ash) into the pre-dispersing device 9, please refer to figure 1 , 5 As shown, the feeding device 32 disclo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com