Self-propelled type aggregate crusher with remote automatic control system

An automatic control system and crusher technology, applied in the field of construction machinery, can solve the problems of unreasonable space utilization, lack of remote hydraulic control and remote electrical control system, long work preparation time, etc., so as to reduce production preparation time and operation and learning costs. , Increase power matching stability and work reliability, and eliminate the effect of power mismatch

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings.

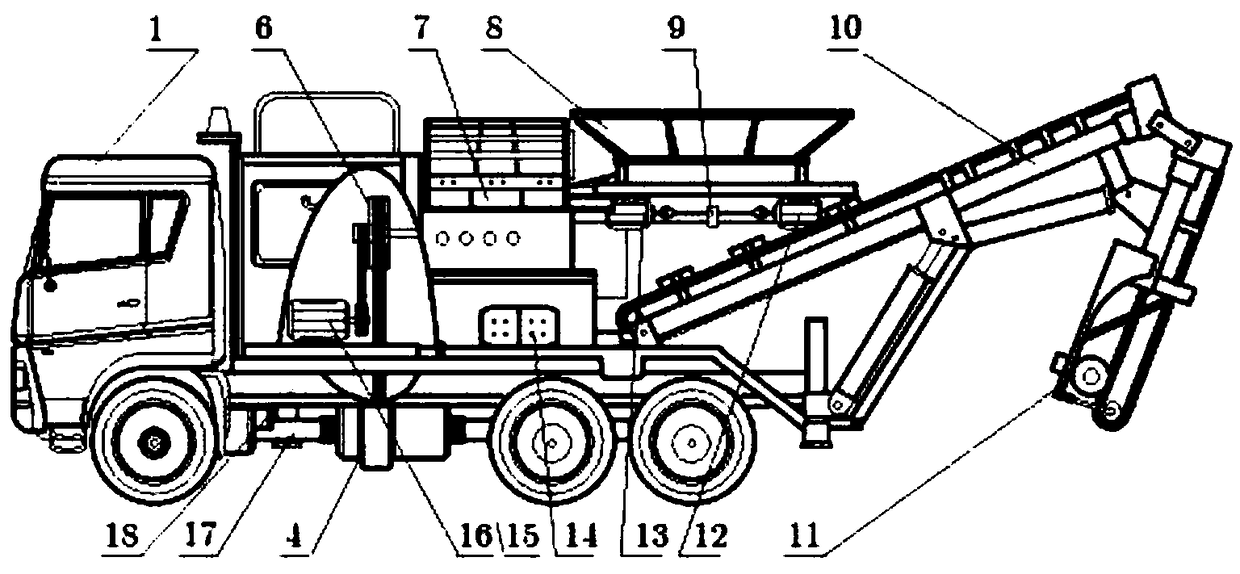

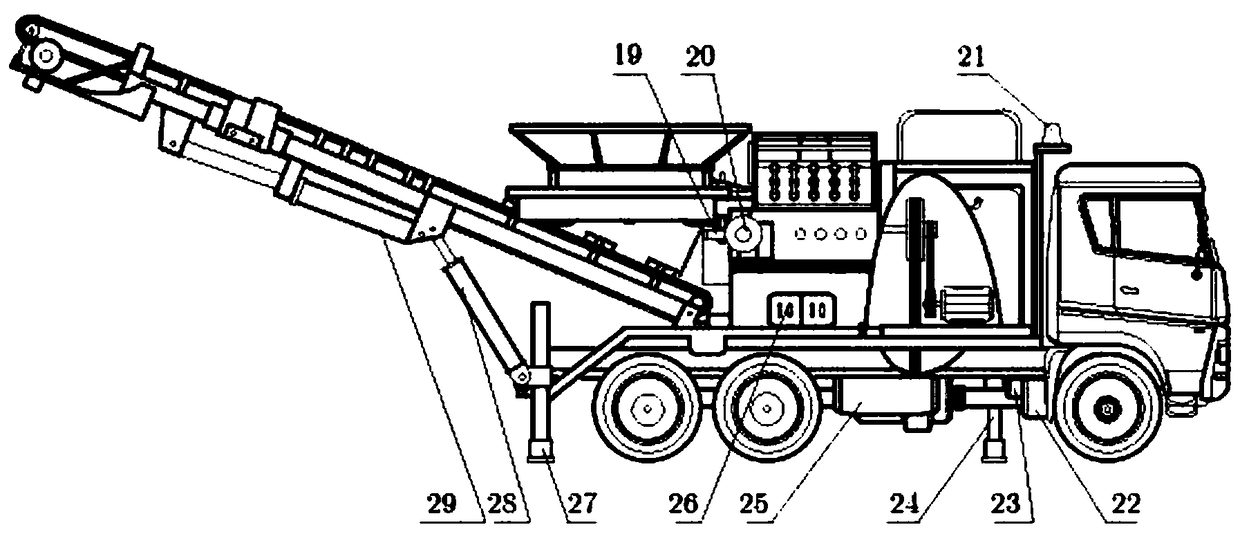

[0017] Such as Figure 1 to Figure 5 As shown, a self-propelled aggregate crusher with a remote automatic control system is mainly composed of a heavy truck 1, an aggregate crusher module, an electrical control module, a power switching module 4, a hydraulic action module, and a truck rear axle input shaft 15, The truck main shaft front section 17 and the truck frame 18 are composed; the aggregate crusher module is composed of the crusher pulley 6, the hammer crusher 7, the feeding device 8 and the discharging device 10; the hammer crusher 7 is installed on the truck frame Above 18, the crusher pulley 6 is connected to the power switching module 4, the feeding device 8 is mounted on one side of the hammer crusher 7 through a hinge, and the discharging device 10 is mounted on the tail of the truck frame 18 through a hinge.

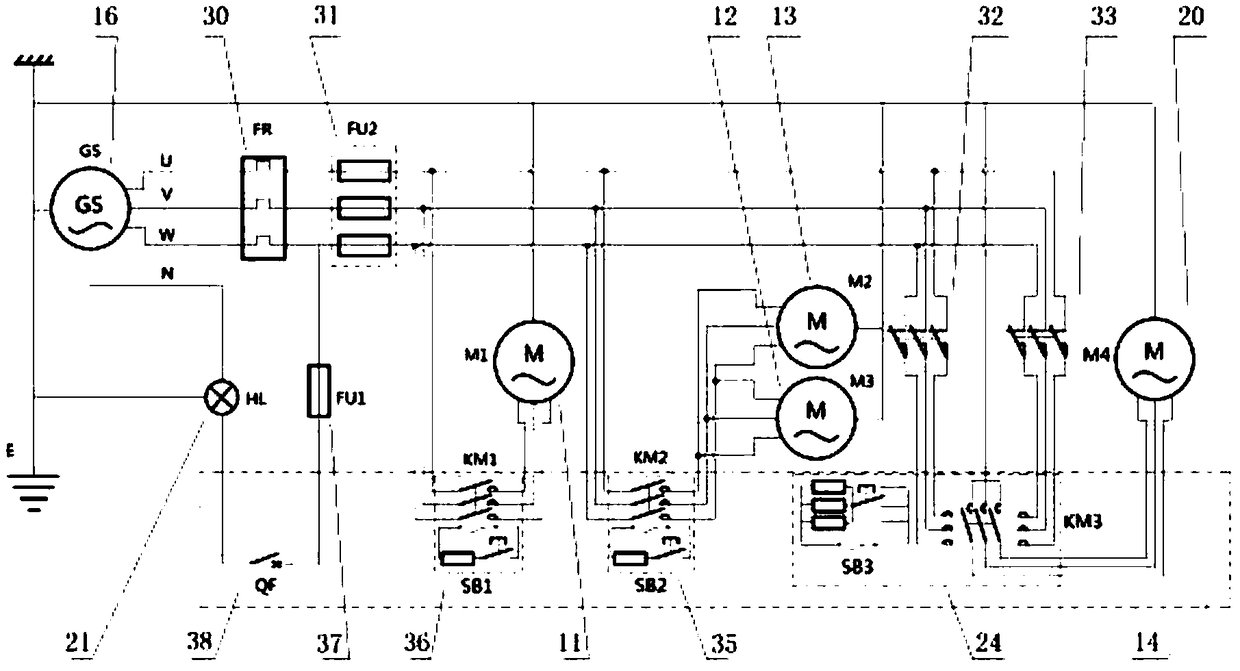

[0018] The electrical control module consist...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com