Ramp self-adaptive control method for tension set value

An adaptive control and tension setting technology, which is applied in the field of steel rolling, can solve the problems of tension fluctuation in the strip tension control area, affect the stability of the tension control system, and the tension setting value changes too fast, so as to meet the requirements of control changes. requirements, ensuring stability and accuracy, and improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

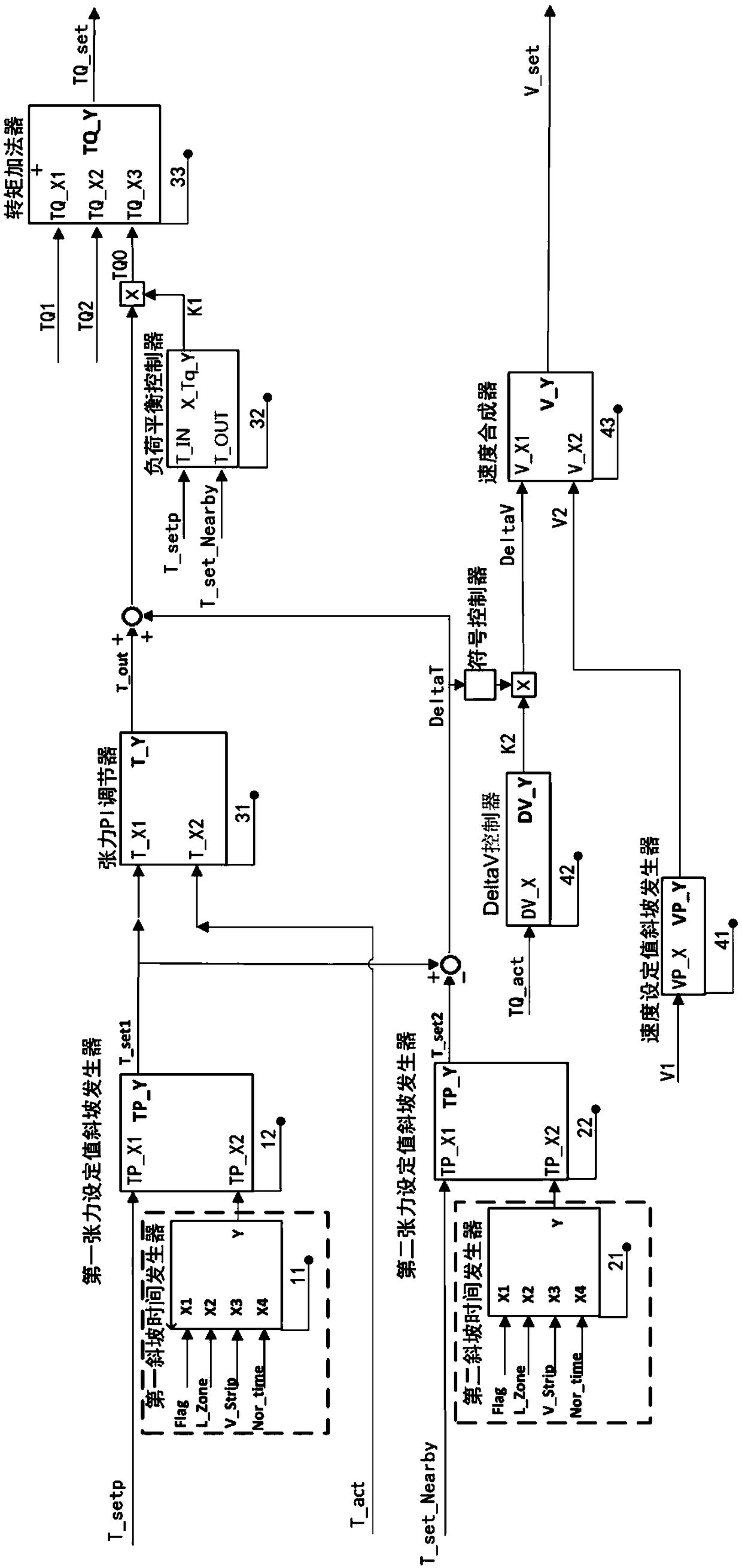

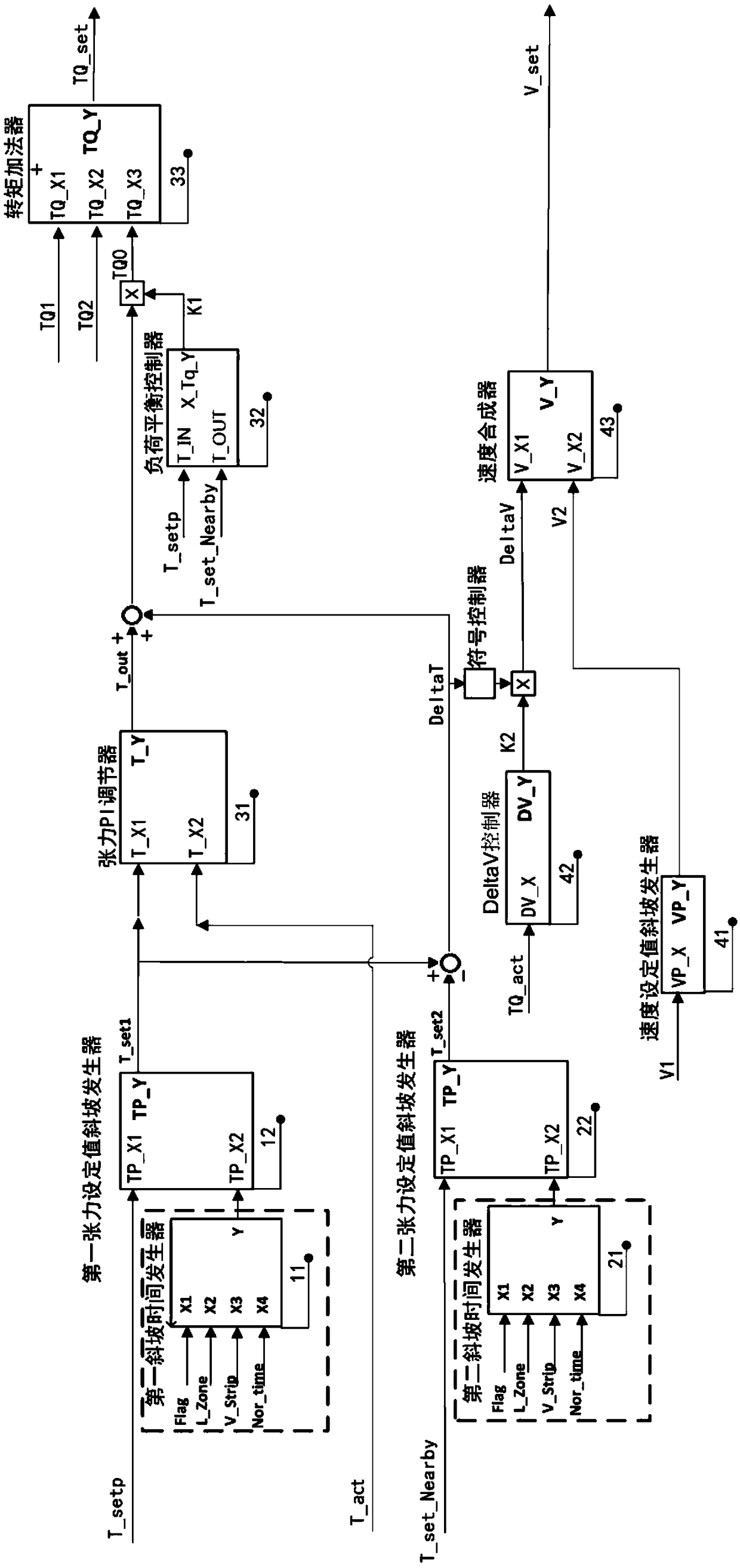

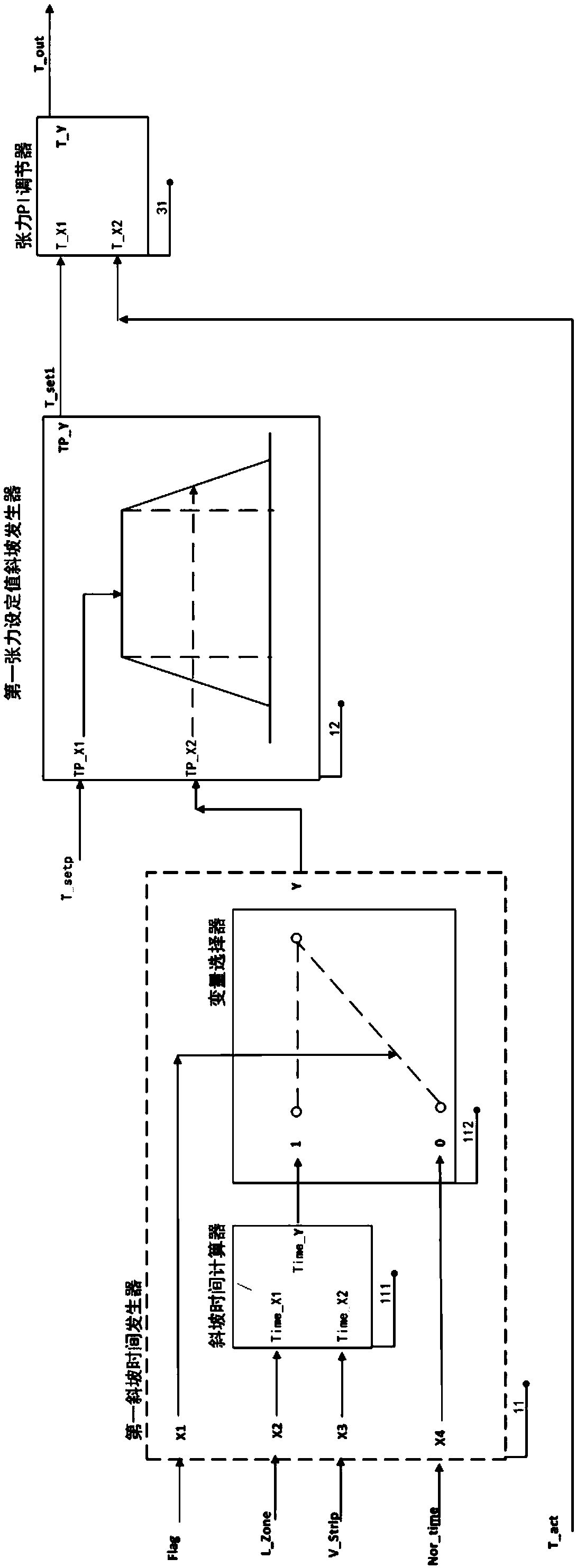

[0020] The present invention includes a programmable controller and a transmission system; the programmable controller includes a first ramp time generator 11, a second ramp time generator 21, a first tension setting value ramp generator 12, a second tension setting value ramp Generator 22 , tension PI regulator 31 , load balance controller 32 , torque adder 33 , speed setting value ramp generator 41 , DeltaV controller 42 , speed synthesizer 43 .

[0021] figure 1 It is the realization schematic diagram of the cold rolling treatment line tension control system of the present invention.

[0022] Such as figure 2 As shown, the process tension set value T_setp issued by the process is used as the input value of the input terminal TP_X1 of the first tension set value ramp generator 12, and the weld seam enters Flag, zone length L_Zone, strip speed V_Strip, and normal time Nor_time as The input values of the first ramp timing generator 11 at the inputs X1 , X2 , X3 , X4 . Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com