A production process and application of a square step adjusting bolt

A technology for adjusting bolts and production processes, which is applied to bolts, threaded fasteners, connecting components, etc., can solve the problems of abnormal noise in automobile steering, low production efficiency, and high processing costs, and achieve material cost reduction, high production efficiency, and The effect of high material utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

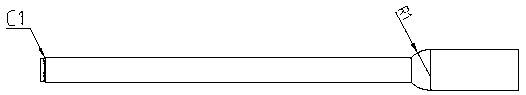

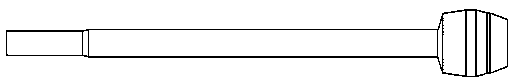

[0040] Such as Figure 1-7 As shown, the present invention discloses a production process of a square step adjustment bolt. The production process of the square step adjustment bolt includes the following steps:

[0041] Step one: Intercept the blanks; the intercepting blanks are applied with an intermittent stepping automatic cutting system, which automatically intercepts the linear raw materials with reasonable diameters out of reasonable lengths, and sends them to the multi-stroke cold heading machine for cold extrusion through the automatic feeding system. Pressure station.

[0042] Step two, forward extrusion of the strong beam rod and tail pre-formed chamfer; the blank cut in step 1 is pushed into the first master die through the first stroke die, and positive extrusion is implemented to realize the strong beam rod and tail Pre-formed chamfer, and eject the pre-formed blank through the ejector rod of the first master mold.

[0043] Step three, head upsetting pre-forming and t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com