Mechanical shaft system revolving error active compensation device based on piezoelectric actuators

A piezoelectric actuator and rotation error technology, which is applied to metal processing machinery parts, other manufacturing equipment/tools, large fixed members, etc., can solve the problems affecting the machining accuracy of machine tools and the improvement of rotation accuracy, and achieve high maintenance costs, Improved rotation error accuracy and low power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

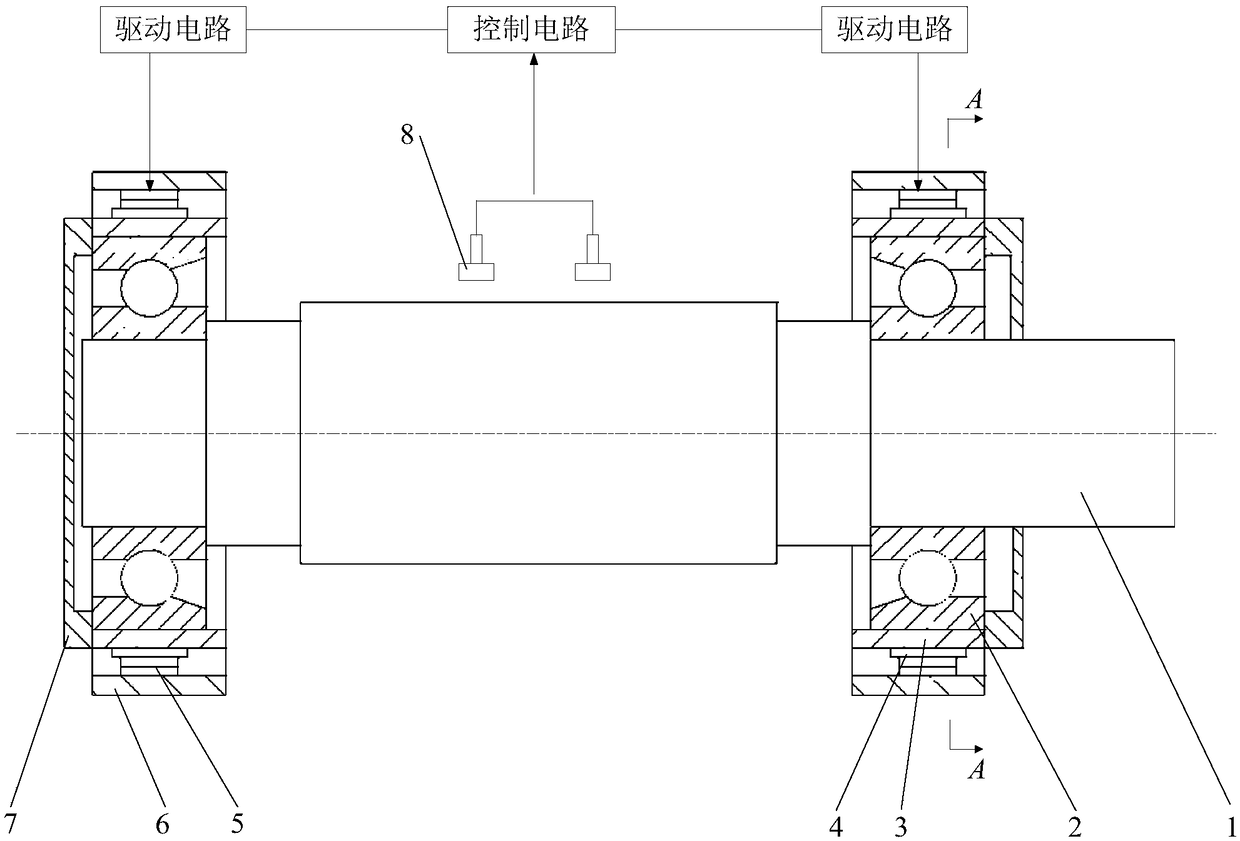

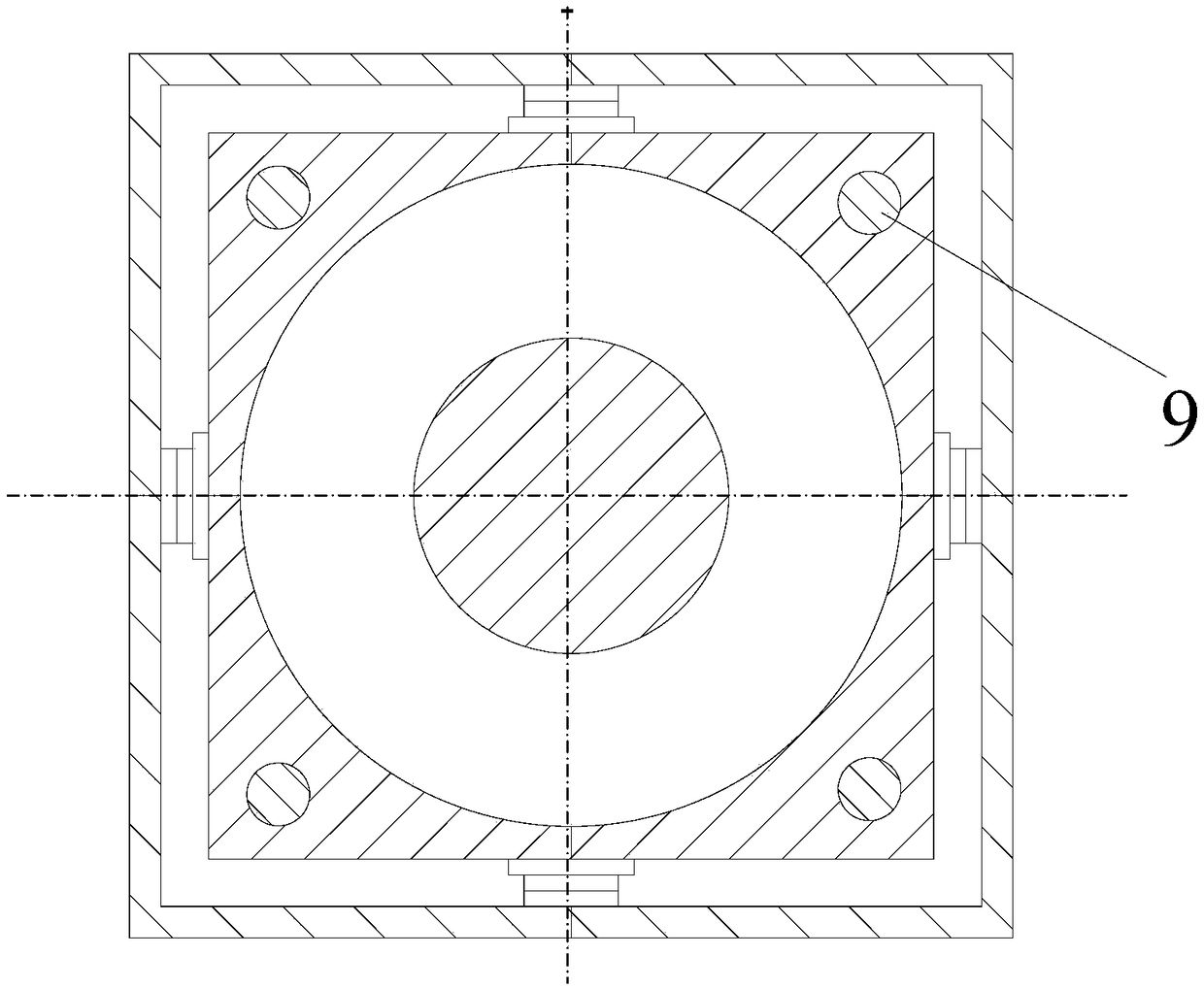

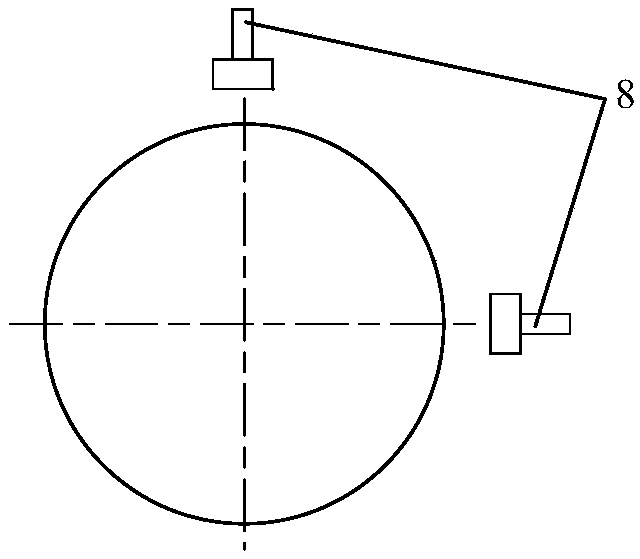

[0033] see Figures 1 to 4 Description of this embodiment: the present invention is realized based on the rotating shaft system. The piezoelectric actuator-based mechanical shaft rotation error active compensation device of the present invention includes a rotating main shaft 1, four sensors 8, a control circuit, and a drive circuit And two bearing assemblies installed on the end of the rotating main shaft 1; each bearing assembly includes a rolling bearing 2, a rolling bearing seat 3, four piezoelectric actuator assemblies, an actuator support 6, and a bearing end cover 7; each The piezoelectric actuation assembly includes an insulating gasket 4 and a piezoelectric actuator 5; the number of the piezoelectric actuation assembly is an even number; two rolling bearings 2 are respectively installed on the main shaft 1 for supporting and providing the rotation of the main shaft Degree of freedom, each bearing end cover 7 is installed on the corresponding bearing seat 3; the inner ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com