Device for coping notch joint surface of piston ring

A technology of expanding rings and gaps, which is applied to the device field of gap joints, can solve the problems of scrapping old rings and increasing repair costs, and achieve the effect of easy grinding, improving grinding efficiency and qualified rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] For ease of understanding, the present invention will be further described below in conjunction with the accompanying drawings.

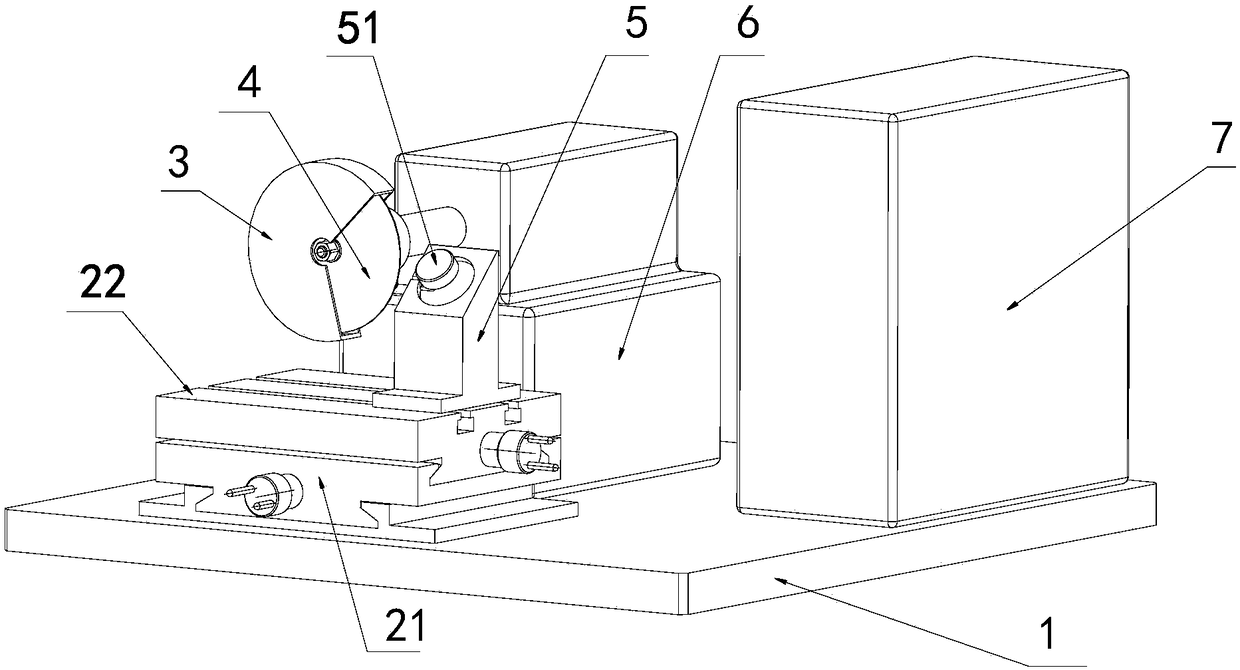

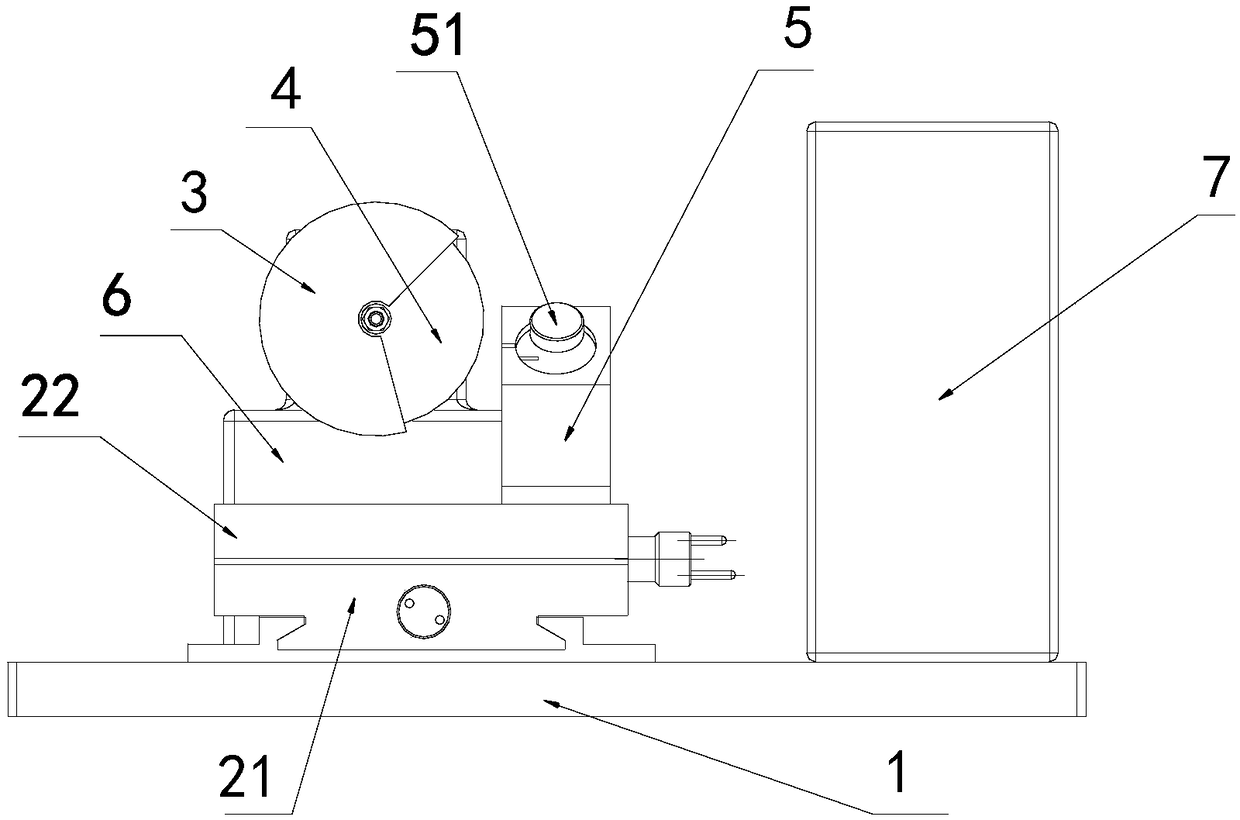

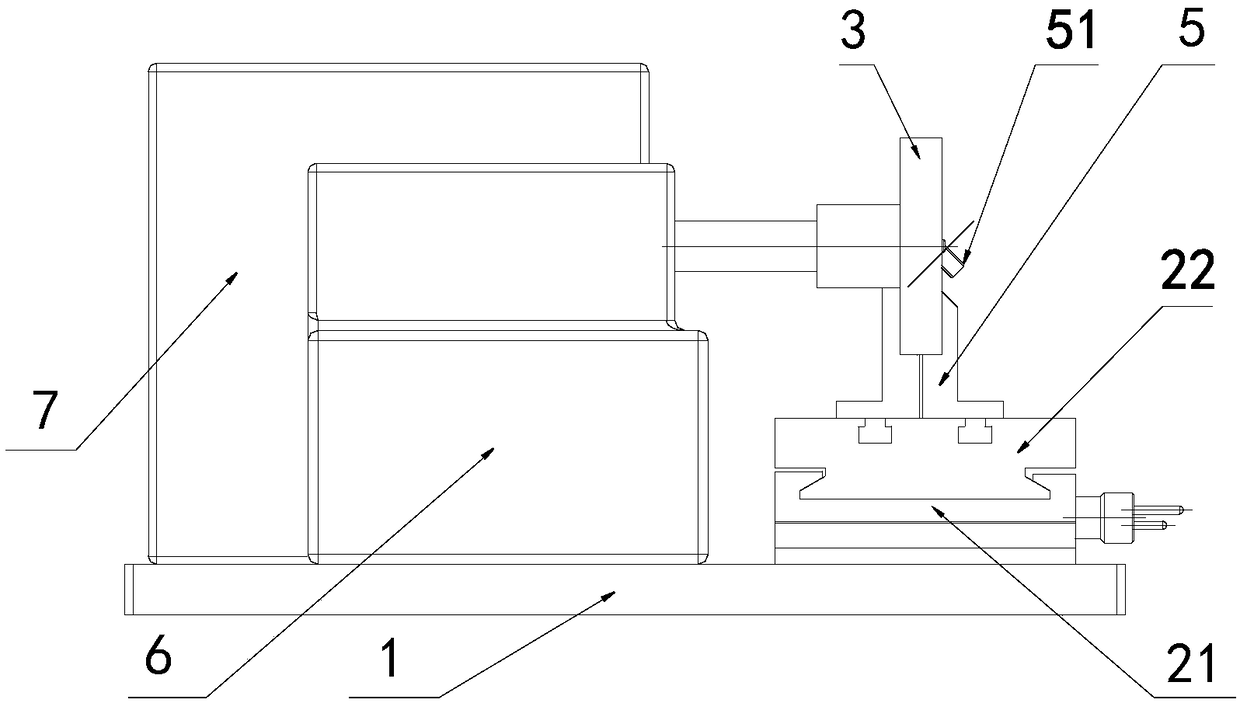

[0030] see Figure 1 ~ Figure 4 , figure 1 It is a schematic diagram of a device for grinding the notch joint surface of the expansion ring provided by the embodiment of the present invention, figure 2 Yes figure 1 Front view of the shown device, image 3 Yes figure 1 Left side view of the device shown, Figure 4 Yes figure 1 Top view of the shown device.

[0031] The device for grinding the gap joint surface of the expanding ring provided by the embodiment of the present invention includes a workbench 1 , a cross slide, a grinding wheel 4 , an expanding ring mounting seat 5 , an expanding ring fixture, a motor box 6 and a distribution box 7 .

[0032] Among them, the cross slide, the motor box 6 and the distribution box 7 are all installed on the workbench 1, the motor box 6 is provided with a motor and a main shaft driven by the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com