Small-sized concrete feeding, stirring and discharging integrated equipment

A concrete and small-scale technology, applied in mixing plants, clay preparation equipment, cement mixing equipment, etc., can solve the problems of inability to achieve automatic feeding and mixing performance, inability to accurately achieve concrete moisture content, lack of concrete mixing equipment, etc., to achieve It is easy to popularize and use, reduce the mixing time, and improve the effect of operation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

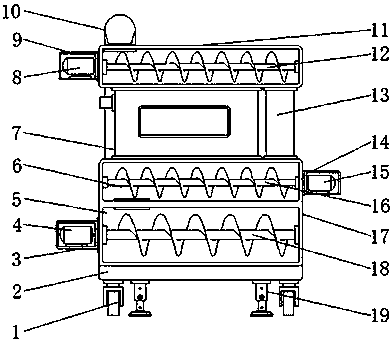

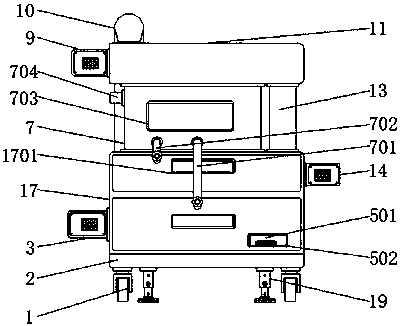

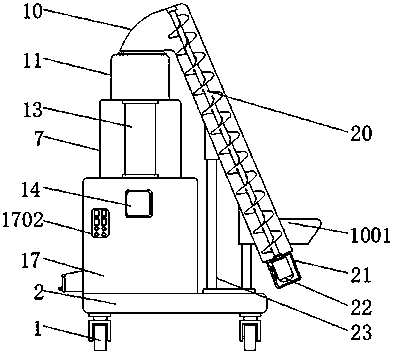

[0019] See Figure 1-4 , An embodiment provided by the present invention: a small-scale concrete feeding, mixing and unloading integrated equipment, including a base 2 and a shell 17. A walking wheel 1 is fixedly installed at the bottom of the base 2, and the walking wheel 1 makes it more convenient to use , The staff can move the equipment according to the actual situation, which improves the flexibility of the equipment. A hydraulic telescopic rod 19 is fixedly installed at the bottom of the base 2 between the walking wheels 1. The hydraulic telescopic rod 19 can fix the equipment to avoid or reduce the equipment. Sliding during operation improves the stability of the equipment during operation. The top of the base 2 on the back of the housing 17 is fixedly installed with the upper barrel 10 through the support rod 23, and the output end of the upper barrel 10 is connected to the mixing chamber 11 , The upper barrel 10 is installed with a fourth bolt stirring rod 20 for inter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com