Preparation method of phosphorus-containing flame retardant

A flame retardant and organic solvent technology, which is applied in the field of preparation of DOPO derivative flame retardants, can solve the problems of limited use, containing low melting point isomers, and the yield needs to be further improved, so as to achieve high purity and increase yield Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

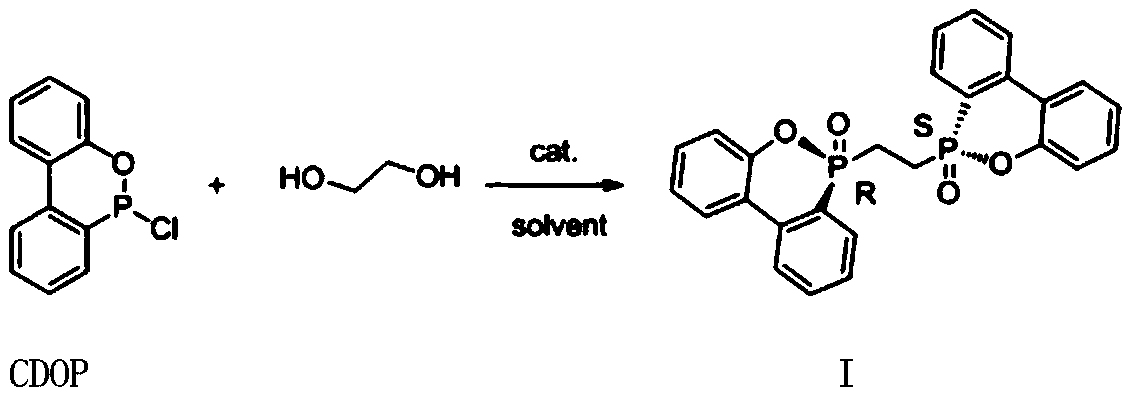

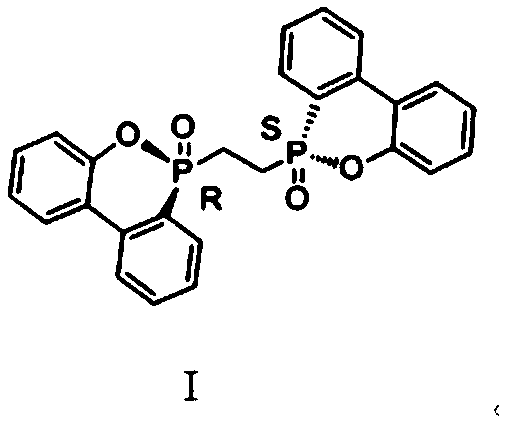

[0029] Add 3.12g of raw material ethylene glycol into 20ml of diphenylmethane, add 15g of triethylamine, control the temperature between -10°C and 10°C, add dropwise the diphenylmethane solution of CDOP (23.68g dissolved in 50ml of diphenylmethane ), dropwise, and react at room temperature for 2 hours; then add 3.75 g of methyl p-toluenesulfonate and 10 g of formic acid, heat up to 180 ° C for 3 h, cool to 50 ° C, add 100 ml of methanol, stir, filter, and wash to obtain 20.93 g of formula I The indicated DOPO analogue, the yield is 90%, 31 P-NMR showed that the proportion of the high melting point isomer was 98.7%, and the melting point was 297-298°C.

Embodiment 2

[0031] Add 6.21g of raw material ethylene glycol into 45ml of diphenylmethane, add 32g of triethylamine, control the temperature between -10°C and 10°C, and dropwise add CDOP diphenylmethane solution (47.50g dissolved in 100ml of diphenylmethane ), dropwise, and react at room temperature for 0.5h; then add 6.42g of methyl benzenesulfonate and 25.46g of formic acid, heat up to 170°C for 3h, cool to 50°C, add 180ml of ethanol, stir, filter, and wash to obtain 43.24g of formula The DOPO analog shown in I, yield is 94%, 31 P-NMR showed that the proportion of the high melting point isomer was 99.8%, and the melting point was 300-301°C.

Embodiment 3

[0033] Add 3.12g of raw material ethylene glycol into 25ml of diphenylmethane, add 16g of triethylamine, control the temperature between -10°C and 10°C, add dropwise the diphenylmethane solution of CDOP (23.85g dissolved in 50ml of diphenylmethane ), dropwise, and react at room temperature for 1 h; then add 3.92 g of methyl p-toluenesulfonate and 15.6 g of acetic acid, heat up to 200 ° C for 5 h, cool to 50 ° C, add 100 ml of acetone, stir, filter, and wash to obtain 20.81 g of formula DOPO analog shown in I, 31 P-NMR showed that the high melting point isomer ratio was 99.2%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com