In-situ core migration chamber and core migration method

A core and in-situ technology, which is applied in the field of in-situ core shifting cabin and core shifting, can solve the problems that the core in-situ cannot be effectively guaranteed, and achieve simple and reliable assembly methods, guaranteed fidelity, and sealing good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

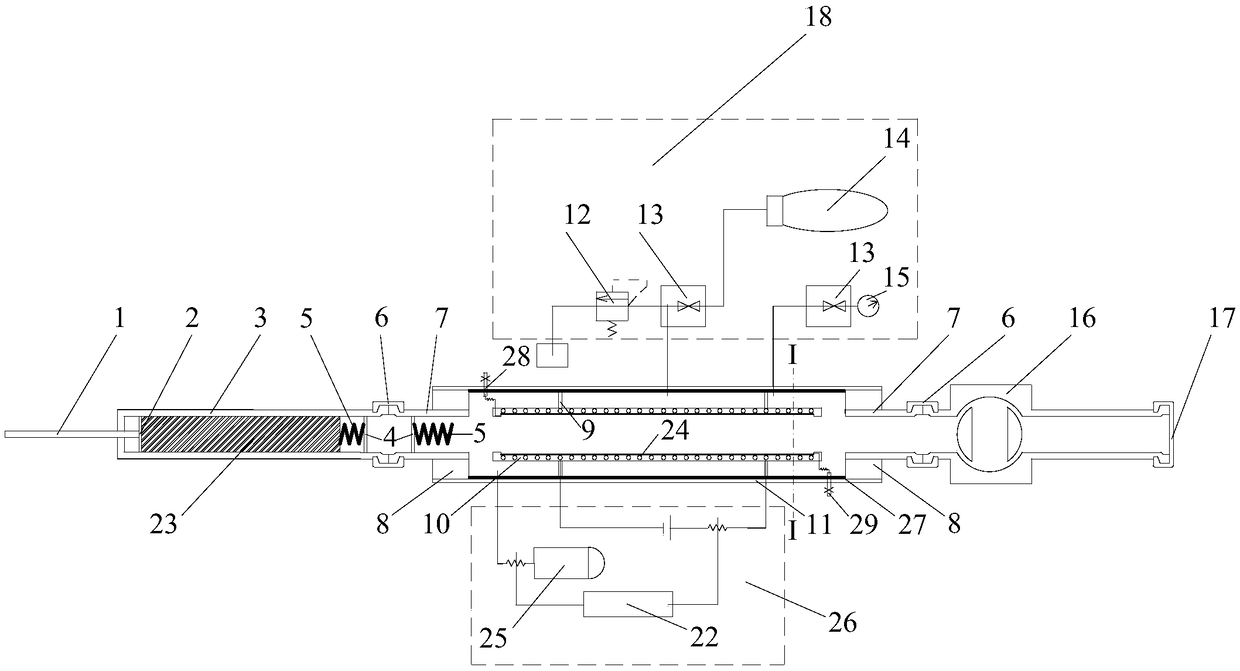

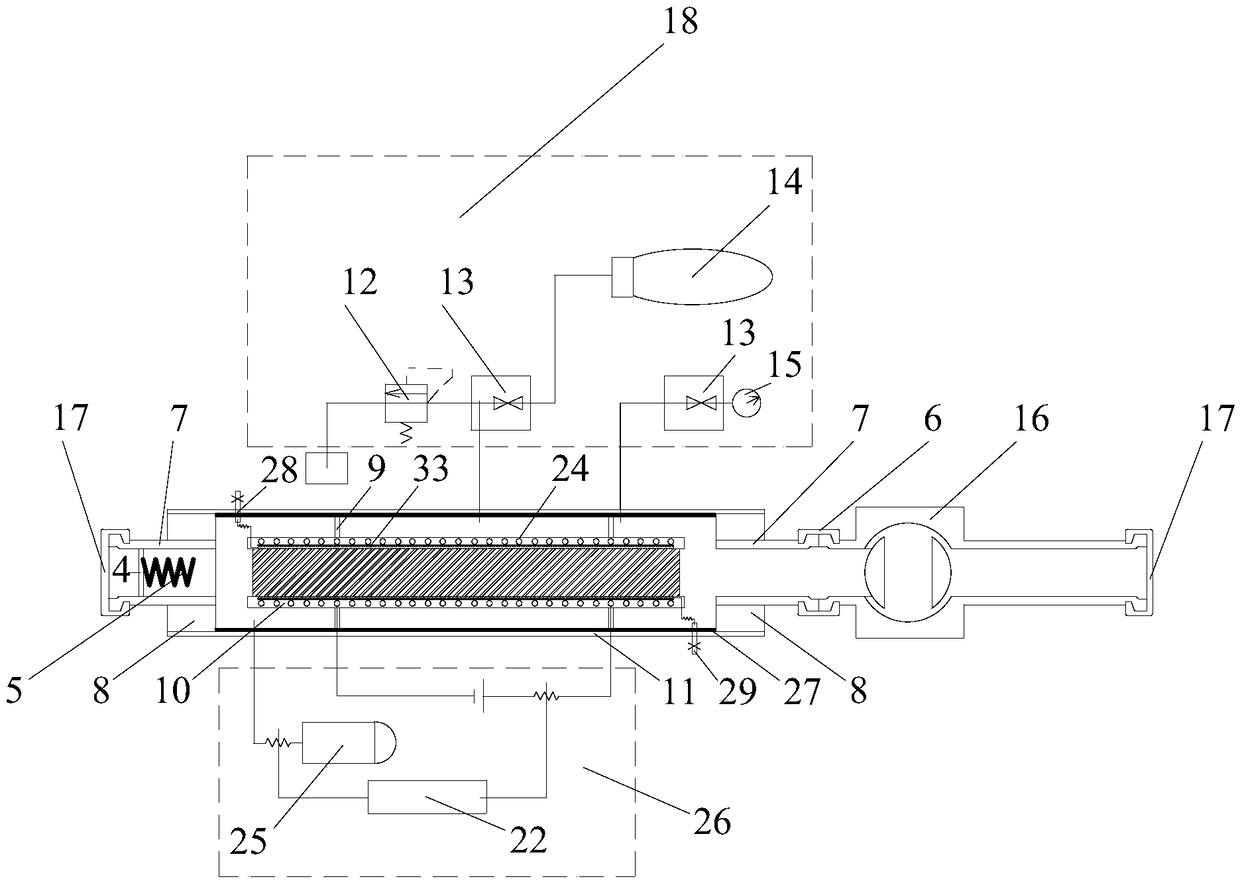

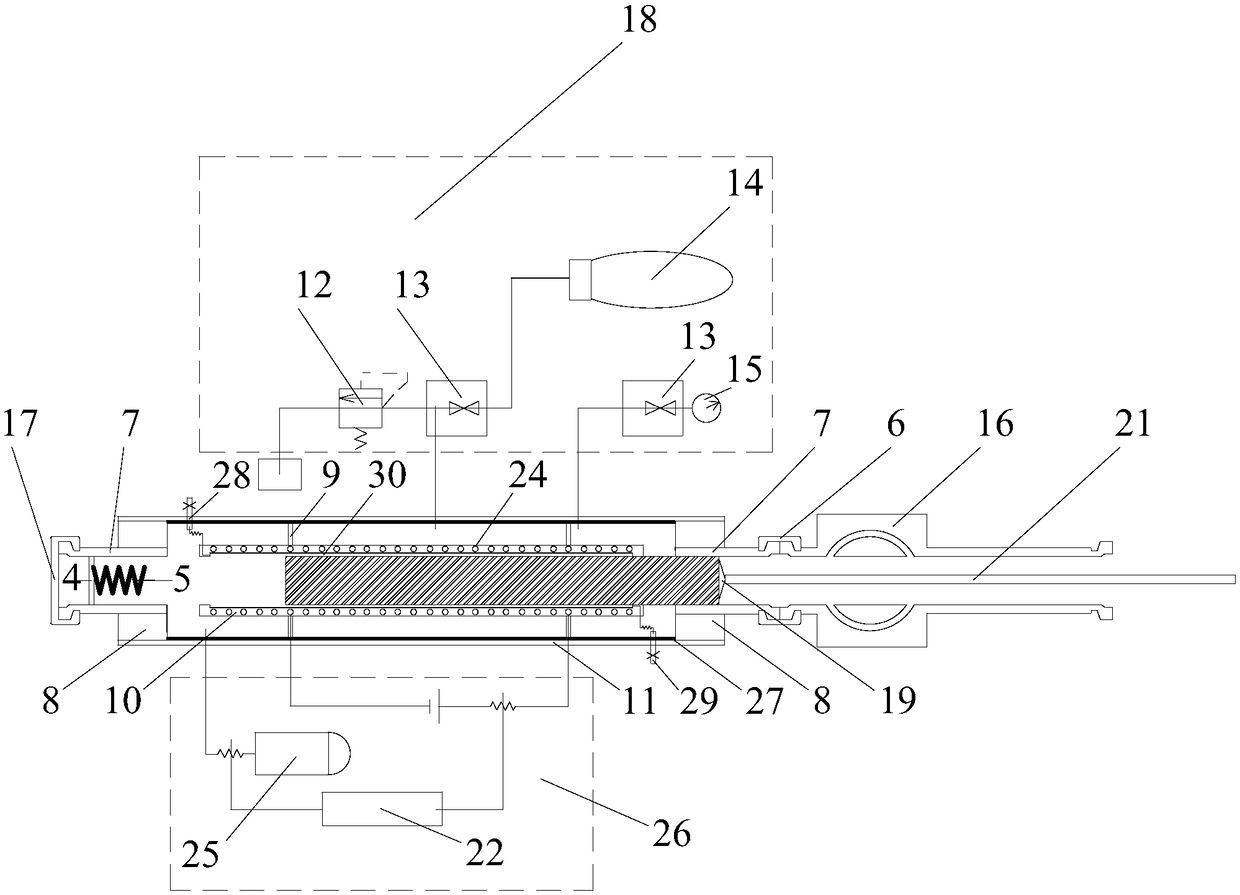

[0027] The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0028] Such as figure 1 As shown, the in-situ core displacement cabin of the present invention can be connected with a fidelity unit equipped with a fidelity cabin, thereby realizing taking out the core from the fidelity cabin to the core storage cabin, and the fidelity unit can use other external Equipment such as fidelity drilling rigs can also be used in this device designed by oneself. The fidelity unit designed in this device to have the best sealing effect with the core compartment 11 includes the fidelity compartment 3 . The left end of fidelity cabin 3 is provided with the aperture that matches with push rod 1, and rock core pusher 2 is also set in the fidelity cabin 3, and push rod 1 links to each other with rock core pusher 2 by opening, specifically as The push rod 1 is screwed and fixedly connected with the core pusher 2 in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com