Screw conveyor gate speed control hydraulic system of shield machine material hoisting device

A lifting device and speed control technology, applied in the direction of fluid pressure actuation system safety, fluid pressure actuation system components, fluid pressure actuation device, etc., can solve the problem of large swing range of segments, different operations, and slow response speed and other problems, to achieve the effect of improving walking safety, convenient and effective operation, and fewer parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

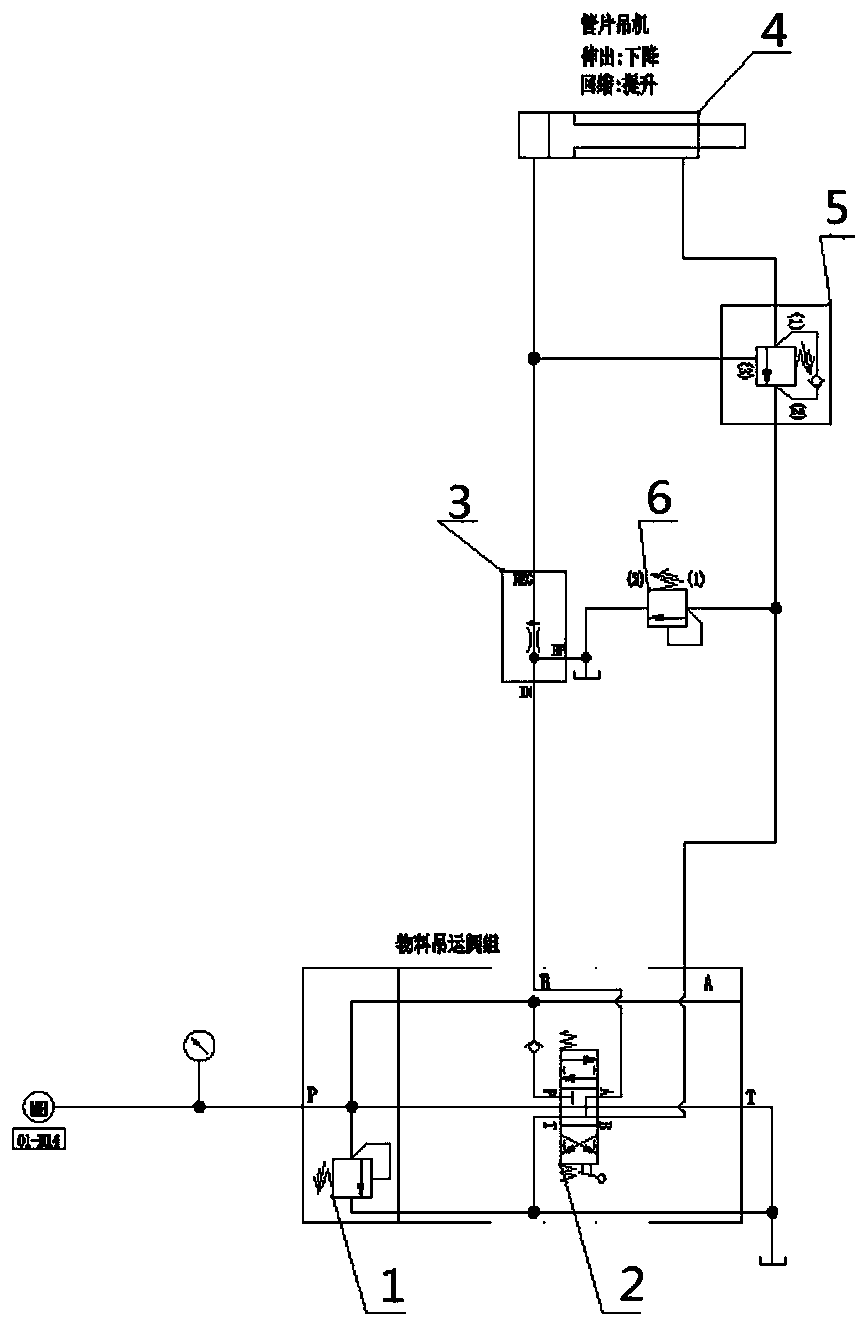

[0015] Refer to attached figure 1 , a speed control hydraulic system for a screw machine gate of a shield machine material hoisting device, which includes a safety valve 1, a manual reversing valve group 2 is connected to the safety valve, and two ends of the manual reversing valve group are respectively connected to two ends of an oil cylinder 4, It is used to control the lifting or lowering of the oil cylinder. There is also a balance valve 5 between one end of the manual reversing valve group and the first chamber of the oil cylinder. The outlet of the balance valve is connected to the second chamber of the oil cylinder. The front end of the balance valve is provided with a relief valve. 6. There is also a pressure compensation flow control valve 3 between the other end of the manual reversing valve group and the second chamber of the oil cylinder. The pressure compensation flow control valve is used to ensure that the walking speed will not be improperly operated by people ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com