Tunable multi-layer damping dynamic vibration absorber and making and mounting method thereof and vibration absorbing method thereof

A dynamic vibration absorber and damping technology, which is applied in the direction of spring/shock absorber manufacturing, shock absorber, spring/shock absorber design characteristics, etc., can solve the problem that the natural frequency cannot realize broadband and small-scale fine-tuning, and achieve high efficiency Vibration reduction treatment, suppression of compression deformation, and improvement of vibration and noise reduction effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

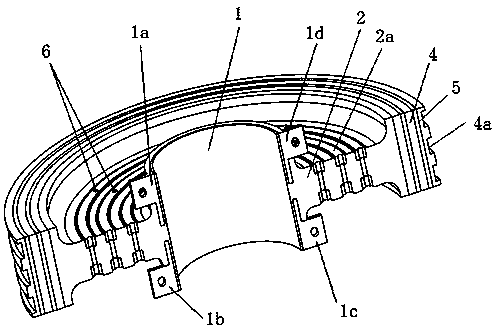

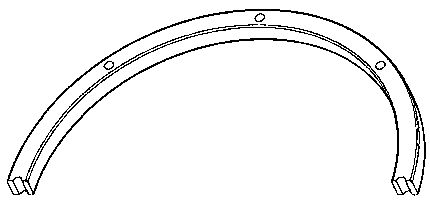

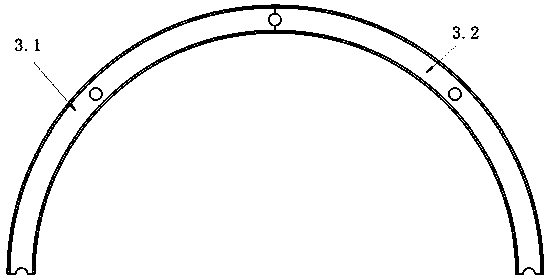

[0053] Please refer to Figure 1 to Figure 10 , a tunable multi-layer damping dynamic vibration absorber, including an inner ring adapter ring 1, a basic rubber layer 2, an inner ring mass layer 3, an outer ring mass layer 4, and an outer ring that can be installed on a pipeline or a shaft system Ring ring damping layer 5, mounting hole 6 in the groove, bolt 1 7a, bolt 2 7b, nut 1 8a, nut 2 8b, outer ring fixing ring 9. The adapter ring 1 of the inner ring, the basic rubber layer 2, the annular quality layer 3 of the inner ring, the annular quality layer 4 of the outer ring, the annular damping layer 5 of the outer ring, and the fixing ring 9 of the outer ring are all in the shape of a ring or a hoop or Both ends are open and the middle is a hollow cylinder. The base rubber layer is connected to the outer peripheral surface of the inner ring adapter ring, and the inner ring adapter ring and the base rubber layer are vulcanized together in sections. An inner annular quality l...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap