Built-in solenoid valve type variable damping shock absorber

A technology of solenoid valves and shock absorbers, applied in the direction of shock absorbers, springs/shock absorbers, shock absorbers, etc., can solve the problem of reducing the response speed and integration degree of variable damping shock absorbers, solenoid valves and shock absorbers Problems such as the separation of the main body of the device and the increase of the length of the liquid flow path have been achieved to achieve the effects of compact structure, reduced failure rate, and short stroke path

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings and specific implementation methods (embodiments), but it is not used as a basis for limiting the present invention.

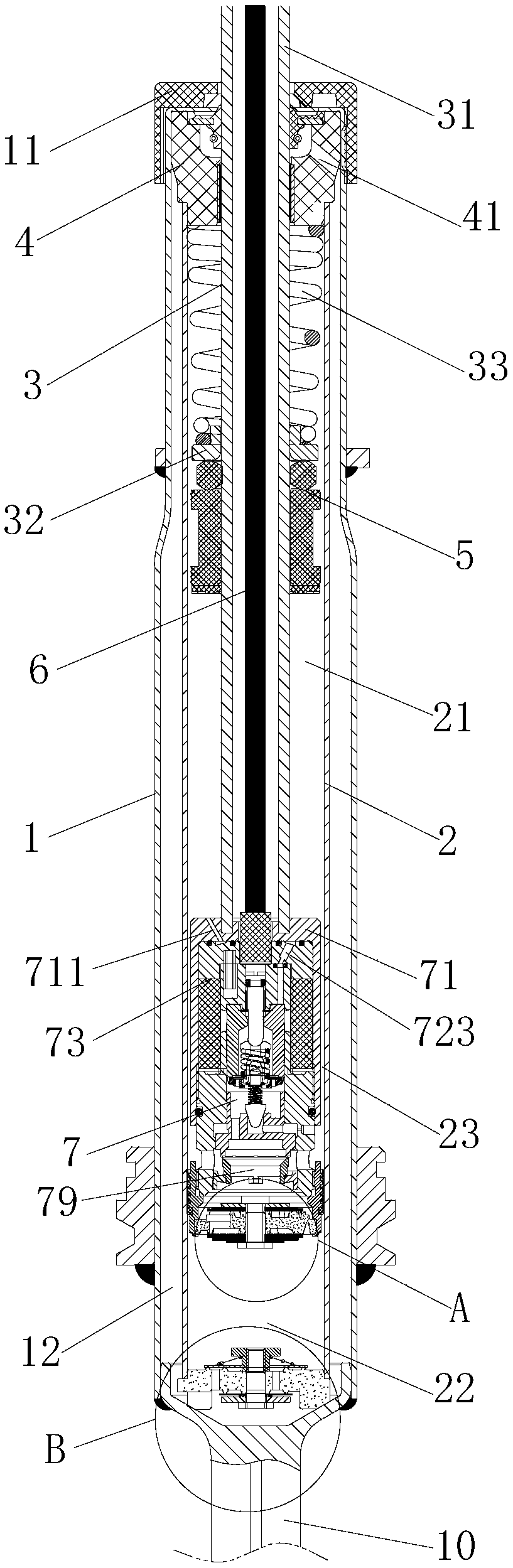

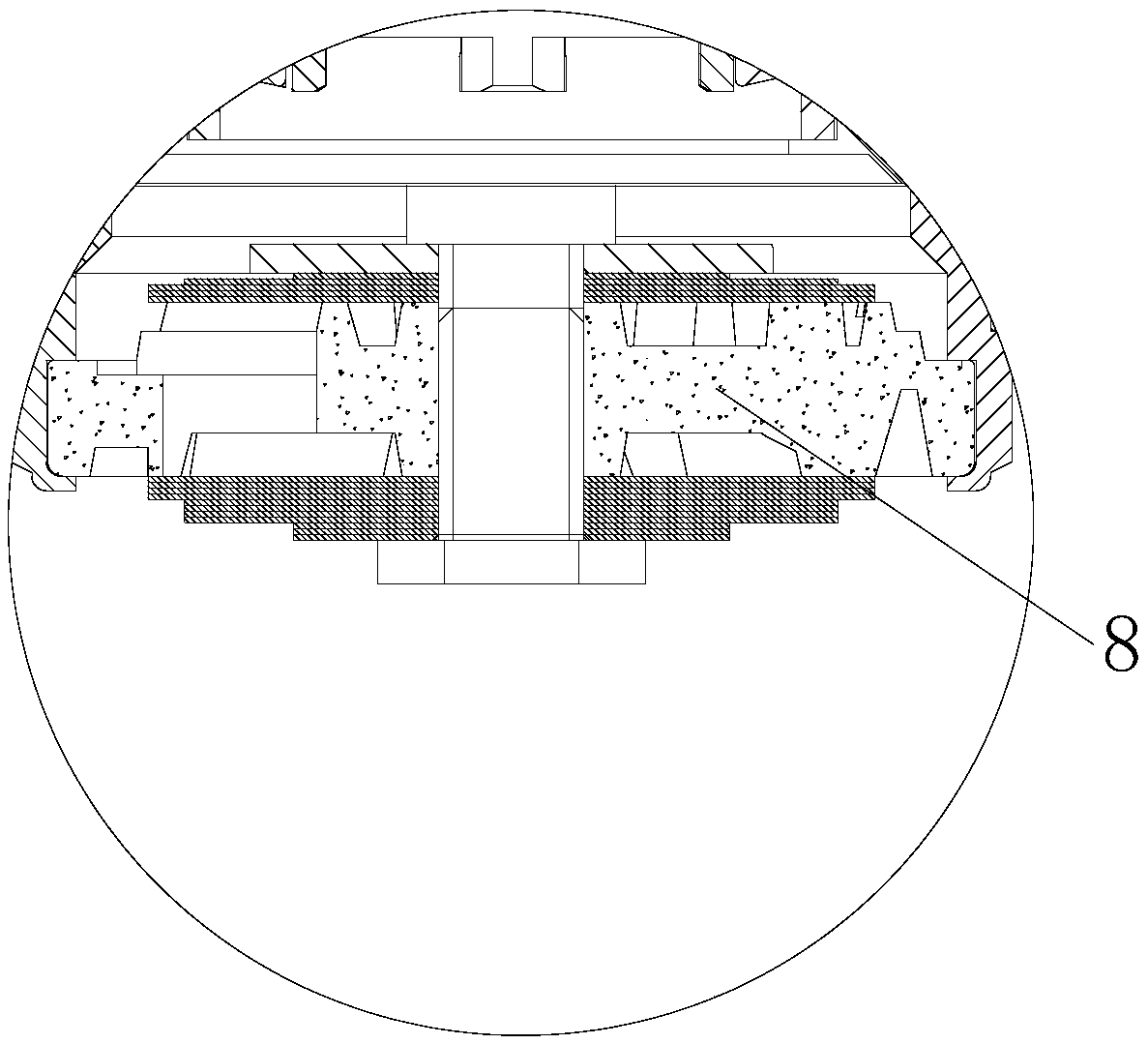

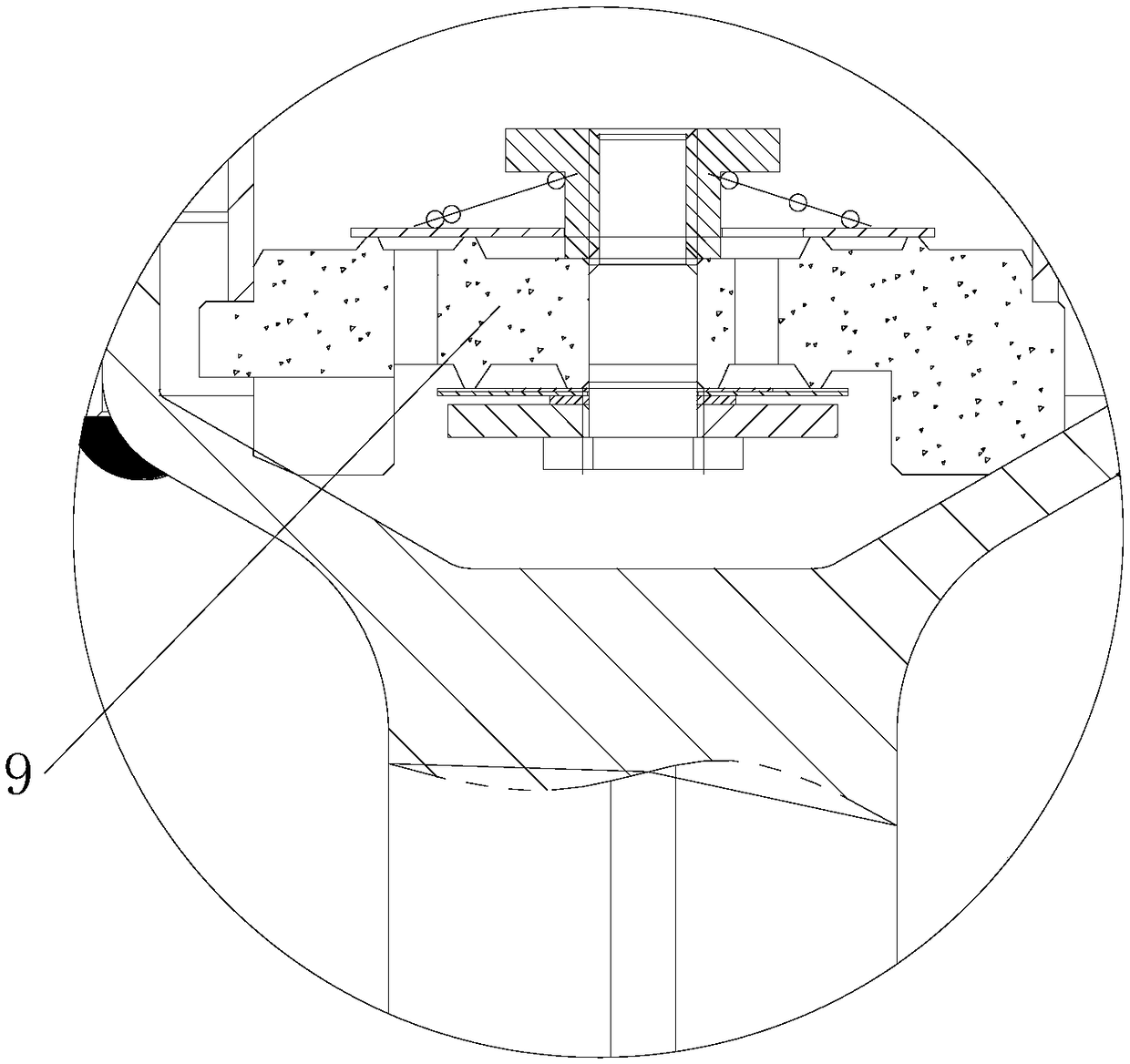

[0020] Such as Figure 1 to Figure 4 The shown built-in electromagnetic valve type variable damping shock absorber is characterized in that it includes a liquid storage cylinder 1, a working cylinder 2 is arranged in the liquid storage cylinder 1, and a working cylinder 2 is formed between the liquid storage cylinder 1 and the working cylinder 2. C liquid flow chamber 12, the working cylinder 2 is provided with a piston rod assembly 3 that can slide relative to it; the lower end of the liquid storage cylinder 1 is connected to the upper end of the coupling fork 10 to form a seal, and the upper end is sleeved with an end cover 11, There is an oil seal guide assembly 4 inside; the upper end of the working cylinder 2 is against the oil seal guide assembly 4,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com