A method for detecting the reactivity of slag

A technology of reaction performance and slag, applied in the field of metallurgy, can solve the problems of large influence of subjective factors and inaccurate test results.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

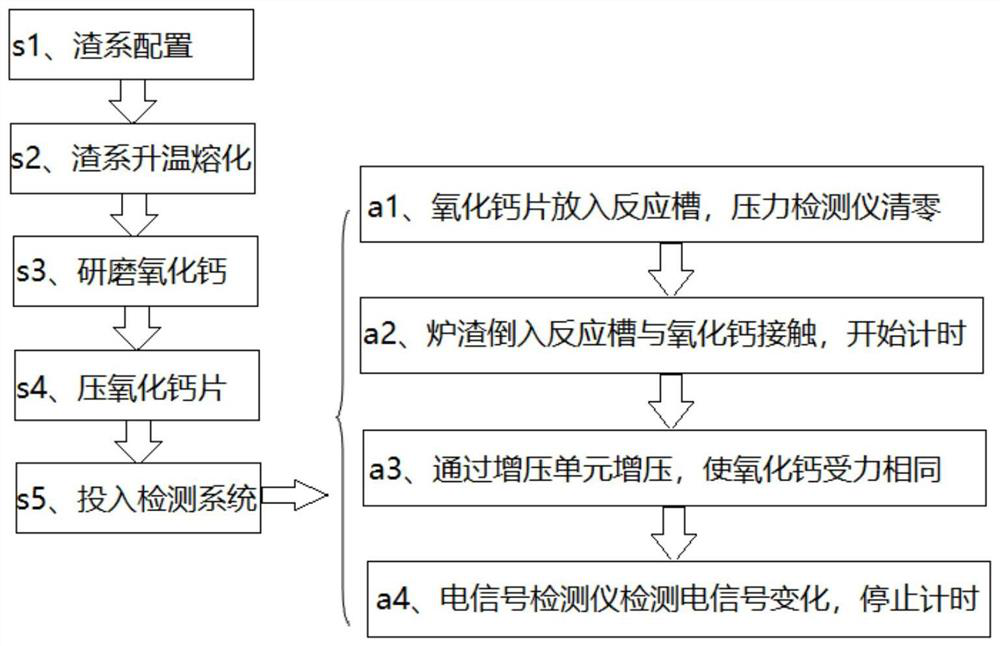

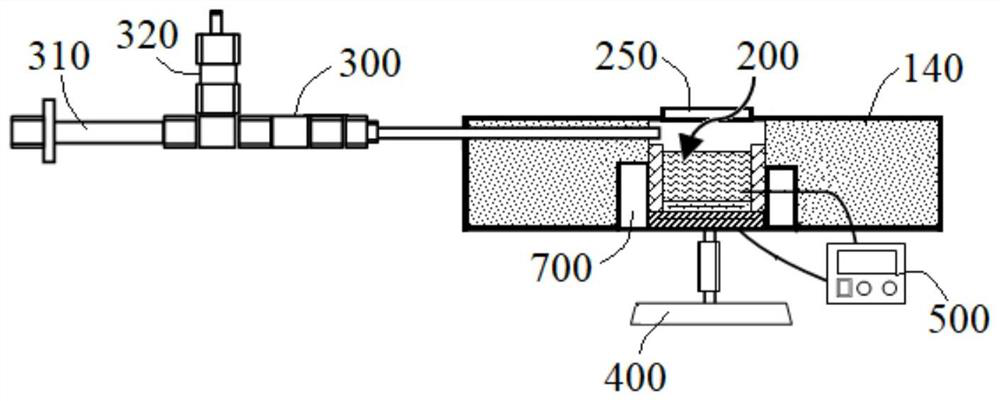

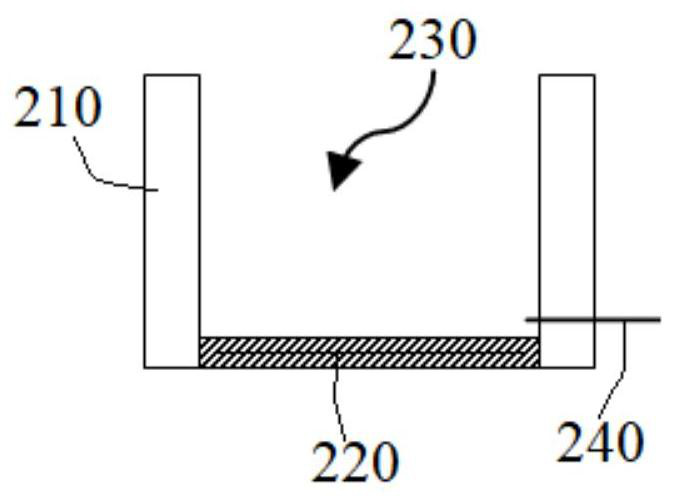

[0049] Such as Figure 1-Figure 4 As shown, a method for detecting the reaction performance of slag in this embodiment adopts a special detection system for the reaction performance of slag, and proceeds according to the following steps:

[0050] S1. Slag system configuration: the slag system is configured with pure chemical reagents CaO and SiO 2 , 3CaO·P 2 o 5 , FeC 2 o 4 as raw material;

[0051] S2, slag system heating treatment: Weigh the quantitatively prepared slag and put it into the heating furnace to heat, so that the slag sample is evenly melted; specifically, weigh the quantitative slag (such as 200g) and put it into the heating furnace, and the furnace temperature is set at 1200- 1400°C, the heating process is three-stage heating, firstly keep warm for 30-40min under the temperature conditions of 300-400°C and 700-800°C, respectively, to prevent the slag sample from being heated unevenly during the melting process of the slag sample due to excessive heating, ...

Embodiment 2

[0067] A method for detecting the reactivity of slag in this embodiment is basically the same as in Embodiment 1, except that it is different in the following steps:

[0068] S2. Slag system heating treatment: Weigh quantitative slag and put it into the heating furnace. The furnace temperature is set at 1400°C. The heating process is three-stage heating. First, keep the temperature at 300°C and 700°C for 30 minutes respectively, and wait for the temperature to rise. At 1400°C, keep warm for another 30 minutes to ensure sufficient reaction between the compounds and then carry out the detection operation;

[0069] S3. Grinding and preparing calcium oxide powder: crush the massive calcium oxide in a mortar and grind it into small particles of calcium oxide, then use a 100-mesh round hole sieve to sieve, put the sieved material into an agate mortar and continue fine grinding for 15 minutes Above, make it pass through a 200-mesh round hole sieve, and use it now to prevent water abs...

Embodiment 3

[0073] A method for detecting the reactivity of slag in this embodiment is basically the same as in Embodiment 1, except that it is different in the following steps:

[0074] S2. Slag system heating treatment: Weigh quantitative slag and put it into the heating furnace. The furnace temperature is set at 1200°C. The heating process is three-stage heating. First, keep the temperature at 400°C and 800°C for 40 minutes respectively, and wait for the temperature to rise. Keep warm for another 40 minutes at 1200°C;

[0075] S3. Grinding and preparing calcium oxide powder: crush and grind blocky calcium oxide into small particles of calcium oxide in a mortar, then use a 150-mesh round hole sieve to sieve, and put the sieved material into an agate mortar and continue fine grinding for 15 minutes Above, make it pass through a 250-mesh round hole sieve, and use it now to prevent water absorption and deterioration;

[0076] S4. Compressing calcium oxide tablets: under a pressure of 12 M...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com