An LED light emitting device for increasing luminous flux density

A light-emitting device and luminous flux technology, which is applied in the direction of electrical components, electric solid-state devices, circuits, etc., can solve the problems of low power, the inability of LED light-emitting devices to be actually put into use, and the inability to increase heat dissipation performance and power synchronously, so as to achieve the goal of increasing density Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] In order to further explain the technical solution of the present invention, the present invention will be described in detail below through specific examples.

[0049] like Figure 1 to Figure 17 As shown, it is a demonstration of various specific embodiments of an LED lighting device with improved luminous flux density related to the present invention.

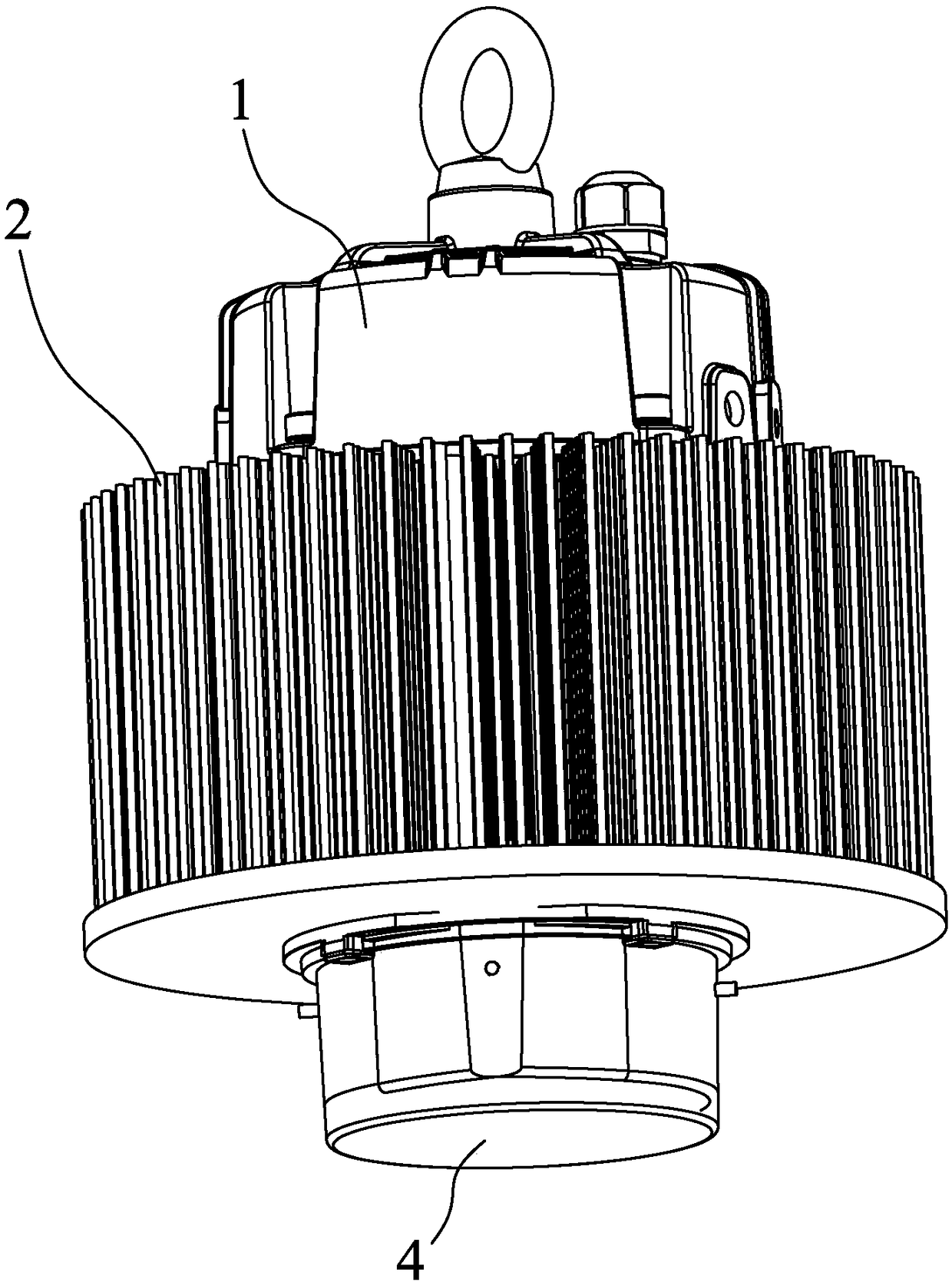

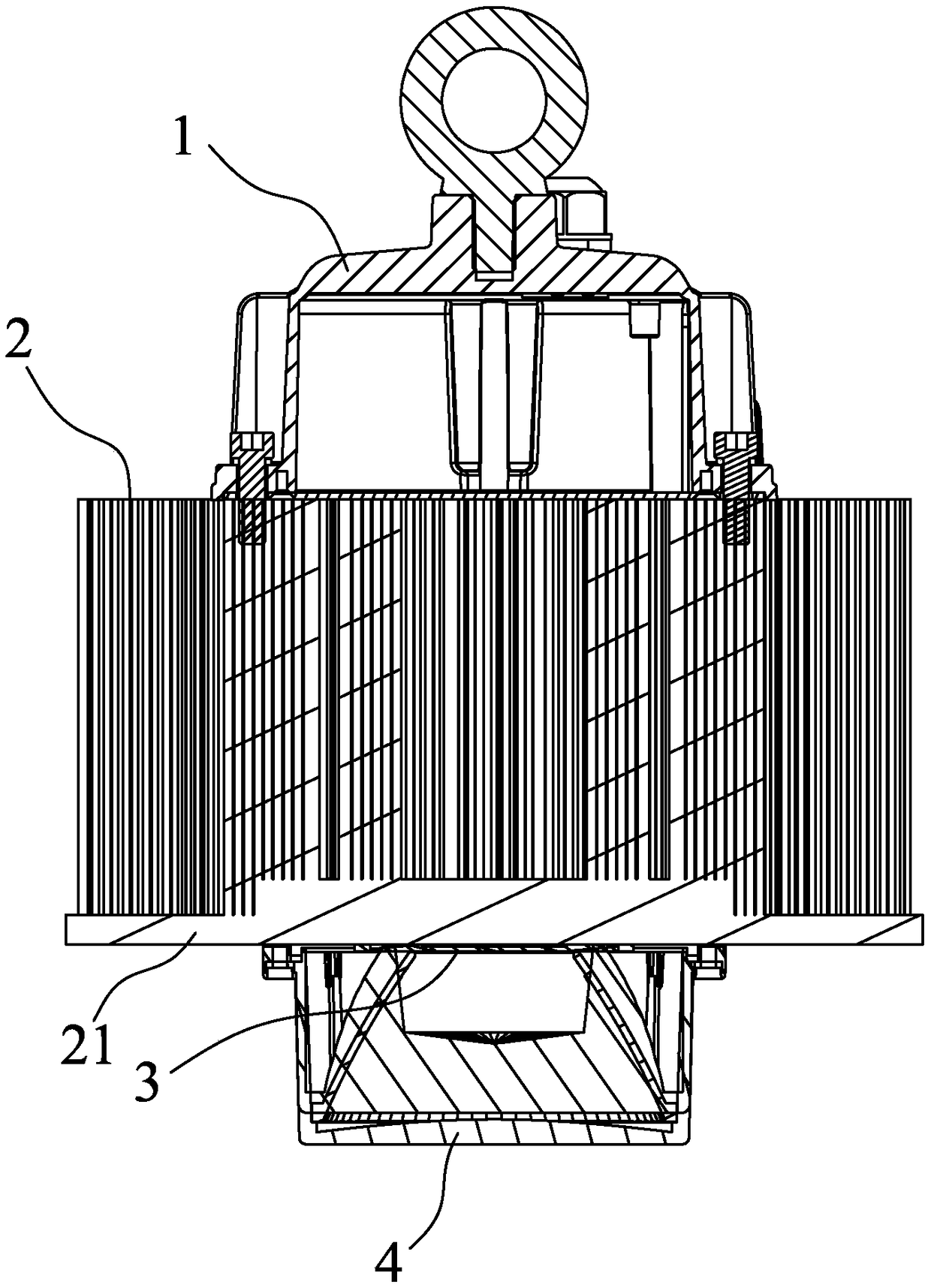

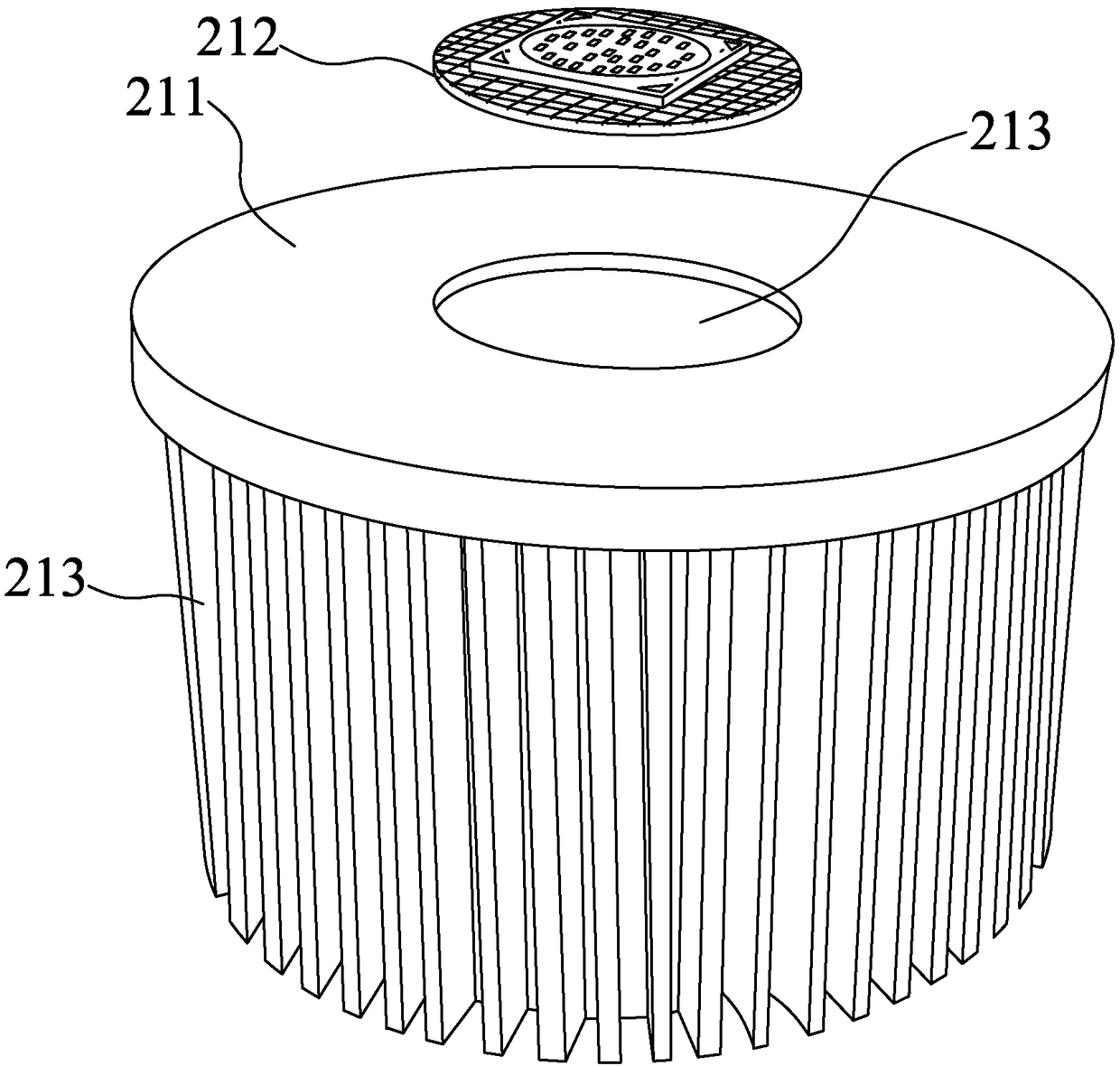

[0050] figure 1 and figure 2 As shown, the present invention relates to an LED lighting device with improved luminous flux density, including a power supply 1 , a heat sink 2 , a light source assembly 3 and a lens assembly 4 located in front of the light source assembly 3 .

[0051] Main features of the present invention are:

[0052] First: the light source assembly 3 has a light source substrate 31 and several LED crystal grains 32 welded and connected to the light source substrate 31. The light source substrate 31 adopts a positive and negative separation substrate; the use of a positive and negative separation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com