Production method and application of straw-sourced ginseng facilitation cultivation matrix

A technology for cultivation substrate and facility cultivation, which is applied in the field of bionic forest soil to achieve the effects of easy operation, improved utilization rate and added value of straw resources, and short soil improvement cycle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

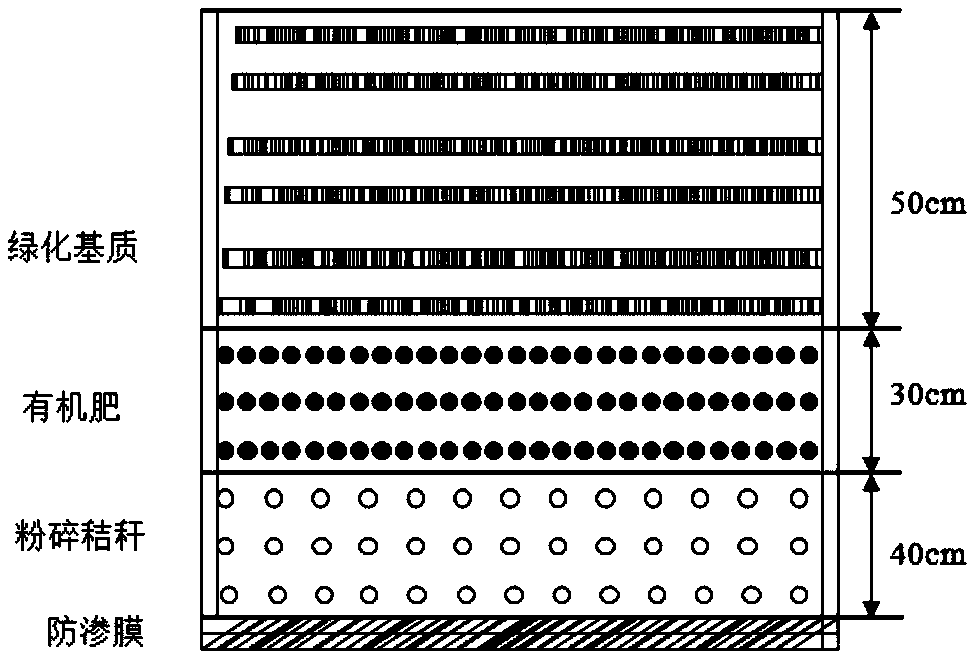

[0022] Develop a cycle mode of straw fermentation-green plant cultivation-ginseng substrate production, focus on simplifying the production process, realize the synergistic utilization of straw source greening substrate-ginseng soilless cultivation substrate, and increase the added value of straw. The collaborative method of straw source greening substrate and ginseng soilless cultivation substrate does not require a special fermentation site, and the fermentation process is gradually completed during the crop growth process, which can save a lot of fermentation sites and human and material resources; the ground temperature can be increased during the fermentation process, which is beneficial to cold regions The crops grow in early spring, and since they have been fermented in autumn and winter, the heat accumulation caused by fermentation will not cause root burn of newly cultivated crops. The patent implementation site is located in Xintunzi Town, Fusong County, Baishan City ...

Embodiment 2

[0033] In 2015, an integrated experiment of straw fermentation-seedling cultivation-ginseng facilities cultivation was carried out in the solar greenhouse of Zuojia Campus of Jilin Institute of Agricultural Science and Technology (44°05' north latitude, 126°10' east longitude).

[0034] The specific implementation technical scheme is as follows:

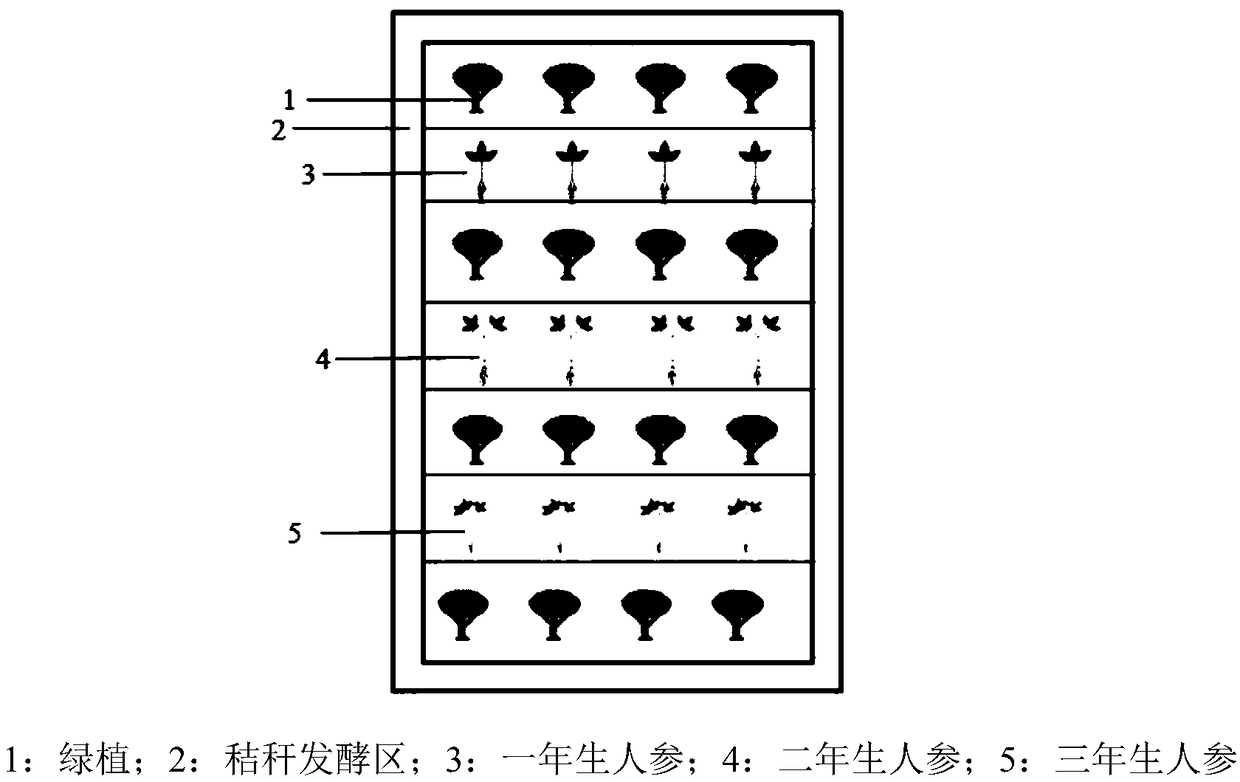

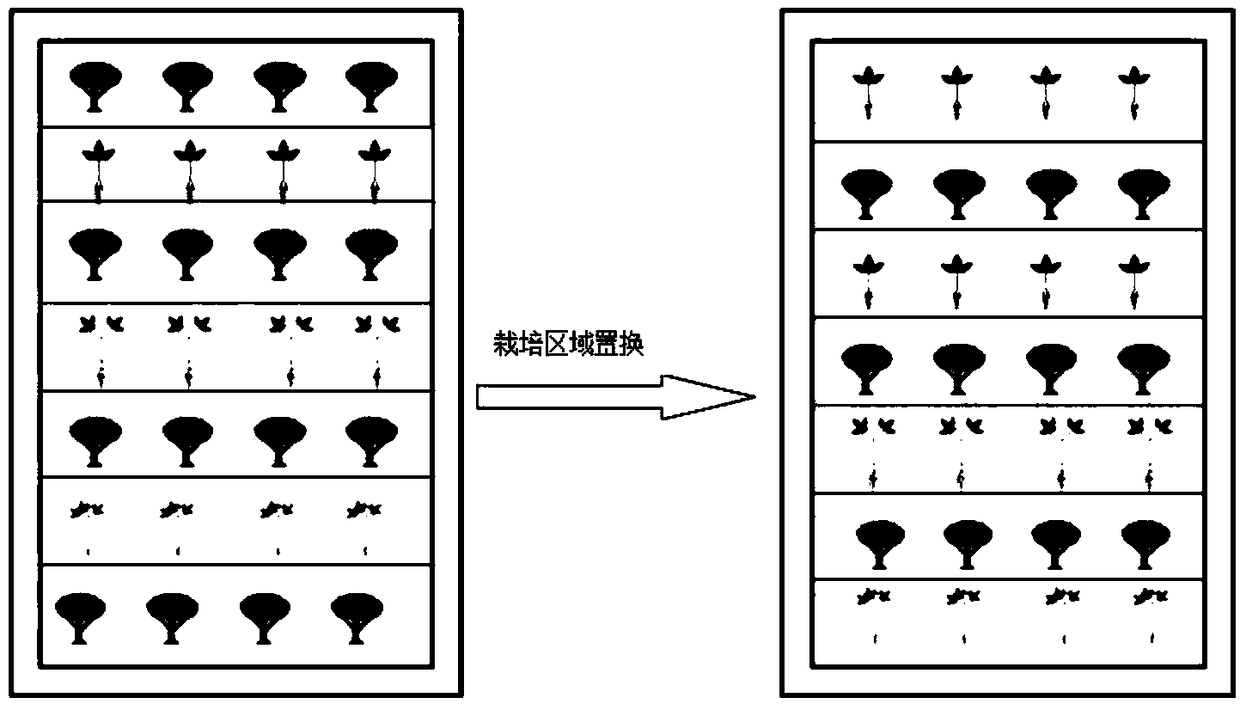

[0035] (1) Different functional areas are planned in the ginseng protected cultivation greenhouse: the surrounding area is the straw fermentation area, the middle is the ginseng cultivation area and the green seedling cultivation area, and the ginseng-green seedling intercropping production mode is adopted. Carry out the greenhouse layout according to the following pattern, from south to north, carry out green plant-three-year-old ginseng-green plant-two-year-old ginseng-green plant-annual ginseng-green plant cultivation ( figure 2 shown); two years later, the ginseng cultivation area was replaced with the green plant cultivation ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com