A medical bone drill with multiple functions

A multi-functional, bone drill technology, applied in the field of medical devices, can solve problems such as troubles, and achieve the effects of reducing working current, prolonging use time, and sufficient power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

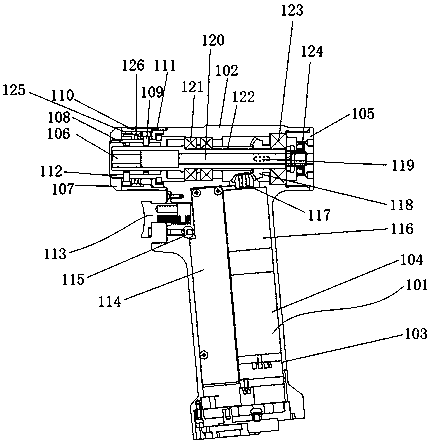

Method used

Image

Examples

no. 2 example

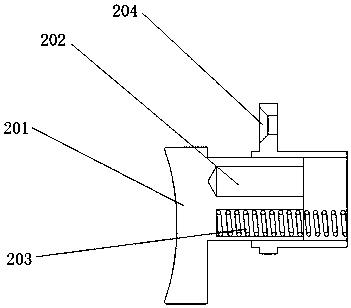

[0051] Such as Figure 5 As shown, the difference from the first embodiment is a multifunctional medical bone drill provided in this embodiment. The drill bit 401 used includes a drill chuck 403 and an output shaft 501. Both ends of the output shaft 501 are connected to the drill chuck 403. The connecting spindle 402 is connected. One end of the connecting spindle 402 is partially inserted into the output shaft 501. The outer periphery of the connecting spindle 402 that penetrates the output shaft 501 is covered with a gasket 502. The other end of the connecting spindle 402 penetrates the tail sleeve 301 and connects Slot 106 connection;

[0052] The outer sleeve of the output shaft 501 is provided with a front sleeve 503 connected to the tail sleeve 301, the end of the tail sleeve 301 away from the positioning groove is connected to the front sleeve 503, and the end of the front sleeve 503 away from the tail sleeve 301 is connected with a second front cover 504 , A sign ring is ...

no. 3 example

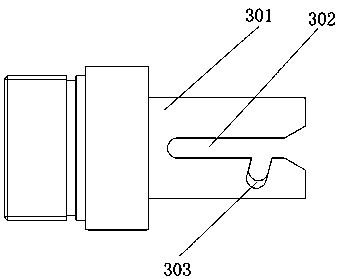

[0056] Such as Image 6 As shown, the difference from the first embodiment is that the multifunctional medical bone drill provided in this embodiment uses a drill 401 that includes a housing 601, a pressure rod 602, and a locking member, and the locking member includes a locking sleeve 603 And the locking chuck 604 and the locking wheel 605 are arranged inside the locking sleeve 603, the housing 601 is sleeved on the locking sleeve 603, and the locking chuck 604 and the locking wheel 605 are provided at the same end of the locking sleeve 603 , The locking chuck 604 is arranged on the inner wall of the locking sleeve 603, the inner wall of the locking chuck 604 is provided with three consistent locking wheels 605, the other end of the locking sleeve 603 is partially inserted into the connecting spindle 402, and the connecting spindle 402 The end away from the locking sleeve 603 is connected to the connecting groove 106, the tail sleeve 301 is sleeved on the connecting spindle 40...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com