Anaerobic fermentation feeding method capable of realizing aeration dense and dilute excrement sewage automatic separation

A technology of automatic separation and anaerobic fermentation, applied in anaerobic digestion treatment, chemical instruments and methods, anaerobic reactor treatment with baffle plates, etc. The effect of manual labor, improving efficiency and accuracy, and improving resource utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

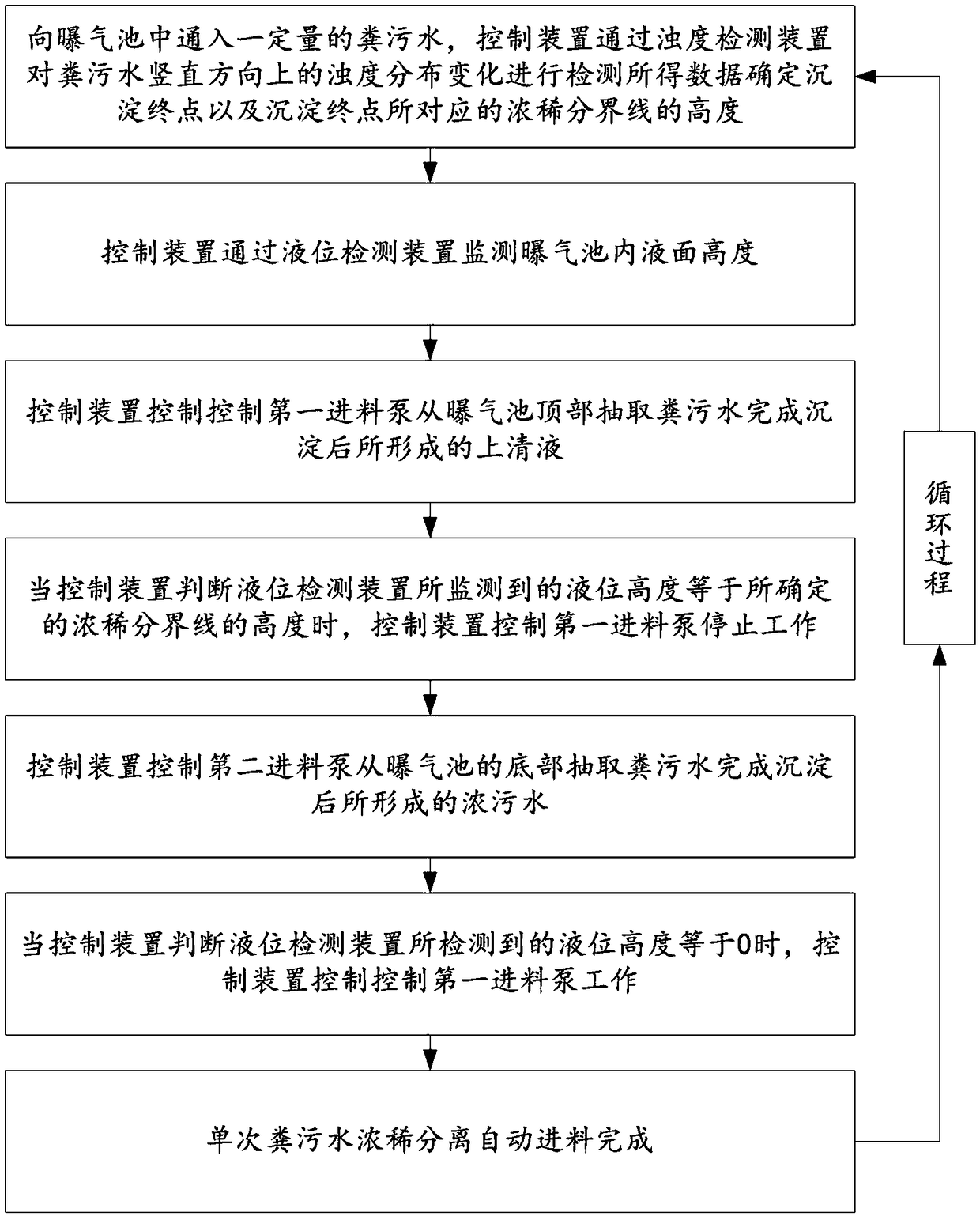

[0039] An anaerobic fermentation feed method for automatic separation of thick and thin manure with aeration, comprising the following steps:

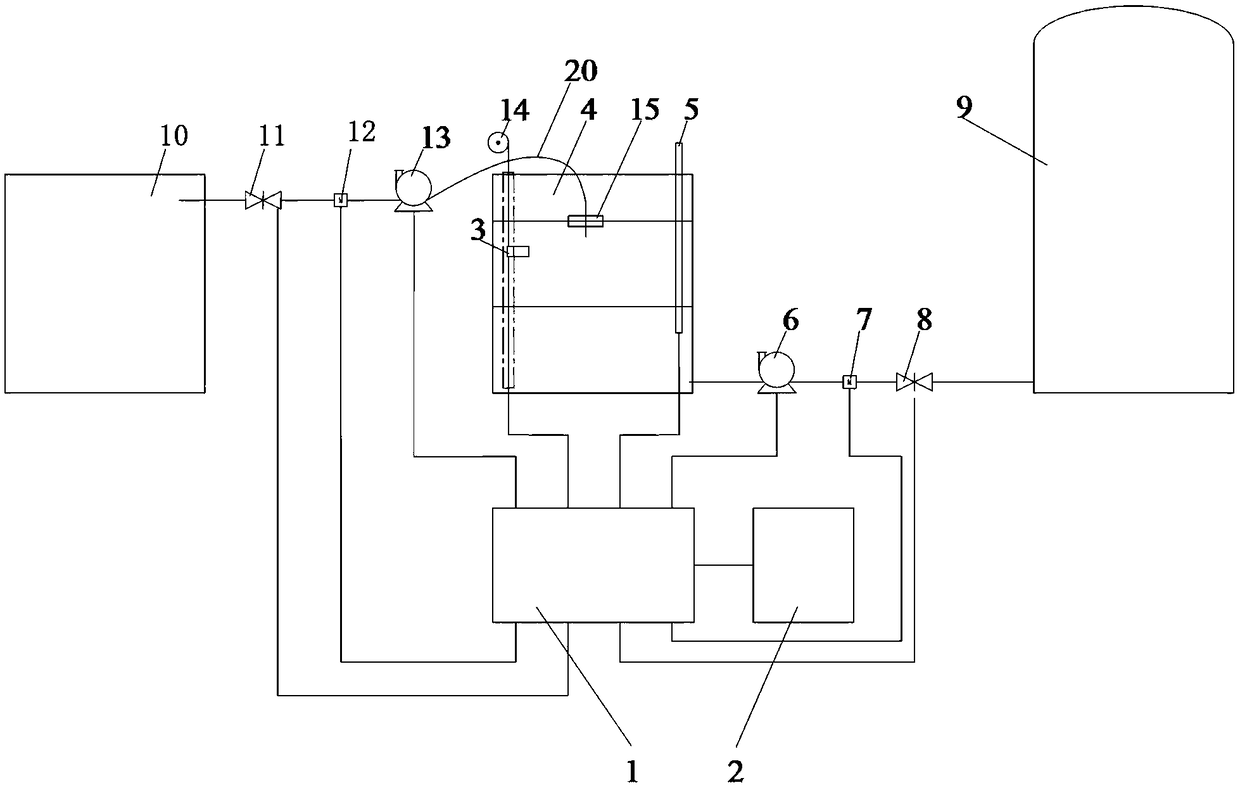

[0040] 1) Pass a certain amount of fecal water into the aeration tank 4, and then periodically use the turbidity detection device 19 to detect the turbidity distribution in the vertical direction of the aeration tank 4 layer by layer, and use two adjacent layers The maximum difference in turbidity between them is stable as the end point of sedimentation, and the liquid level height corresponding to the point where the maximum difference in turbidity occurs is taken as the height of the thick-thin boundary line of fecal sewage, while the liquid above the thick-thin boundary line It is the supernatant, and the liquid below is the concentrated sewage; wherein, the control of the turbidity detection device 19 and the collection and analysis of corresponding data are all automatically completed by the control system;

[0041] 2) extract the...

Embodiment 2

[0070] Difference with embodiment 1, in order to further improve the speed of automatic feeding, shorten the cycle period of anaerobic fermentation, in step 2 and step 3:

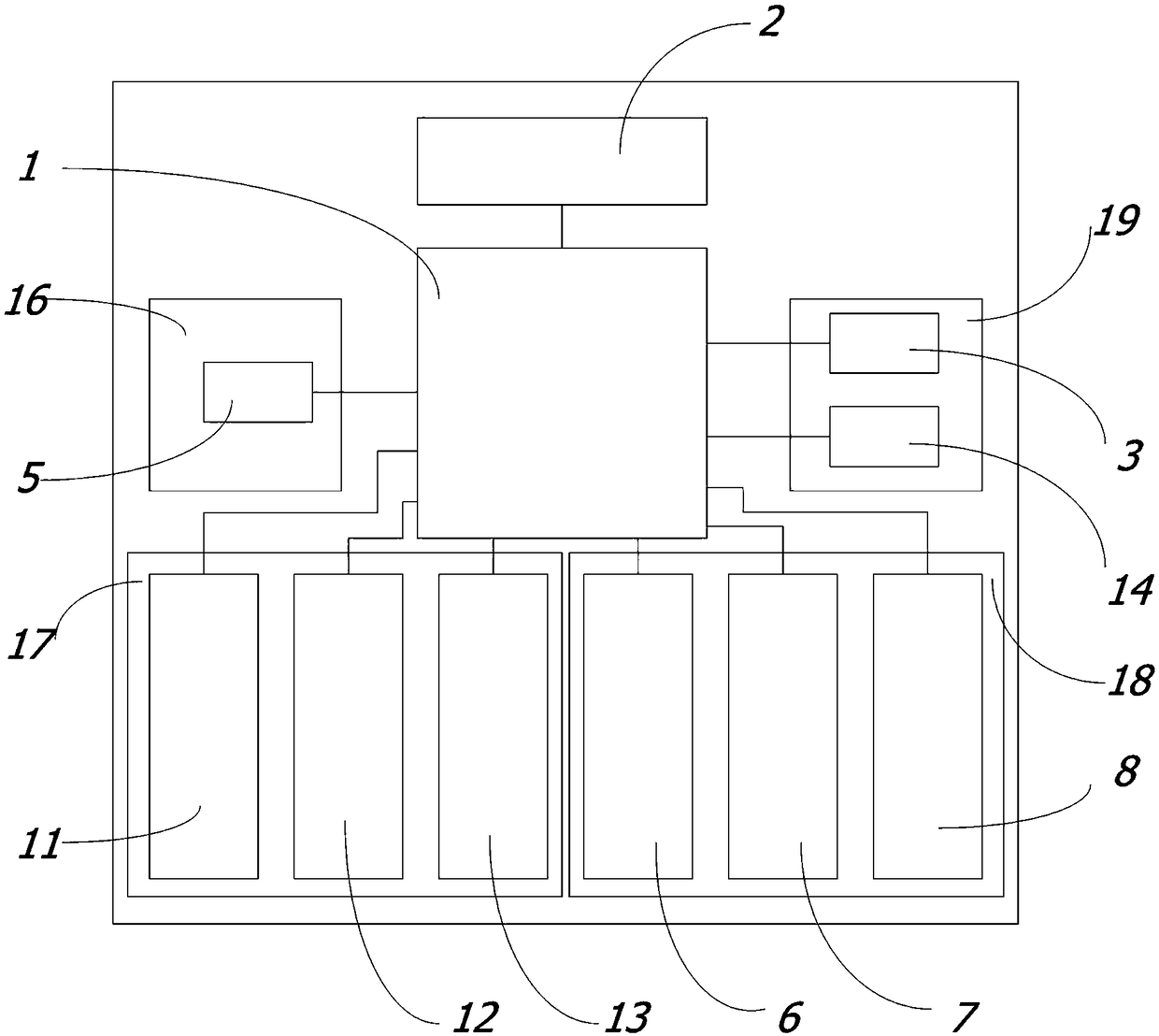

[0071] In the process that the first feeding pump transports the supernatant to the secondary fermentation tank 10, the feed to the secondary fermentation tank 10 is controlled by setting a first flow meter 12 and a first feed valve 11 on the pipeline. Speed; in the process that the second feeding pump is transporting the concentrated sewage to the anaerobic fermentation tank 9, the second flow meter 7 and the second feed valve 8 are set on the pipeline to control the feed to the anaerobic fermentation tank 9 material speed.

[0072] Furthermore, the first flow meter 12, the first feed valve 11, the second flow meter 7 and the second flow valve are connected to the control system, and the corresponding feed flow is automatically monitored and adjusted through the control system.

[0073] The changes made b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com