Deodorized safflower yellow and its preparation method

A technology for safflower yellow pigment and yellow pigment, applied in the field of safflower yellow pigment, can solve the problems of obvious safflower yellow pigment odor, poor deodorization effect, cumbersome process and the like, and achieves fewer processes, good deodorization effect, and color value. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

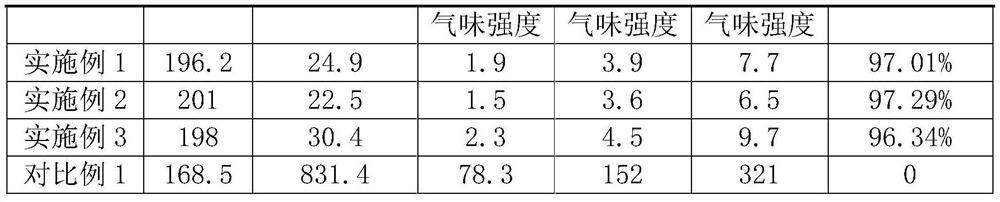

Embodiment 1

[0030] This embodiment provides a method for preparing deodorized safflower yellow, the specific operations are:

[0031] Take 1kg of safflower raw material, add 10L of 30-35°C deionized water at a ratio of 1:10, heat and extract twice at 15-20°C, and filter the extract with a 200-mesh nylon filter to obtain 16kg of filtrate. It is 1.25, refined with 1000ml of AB-8 macroporous adsorption resin, the adsorption capacity is 14BV, the adsorption flow rate is 0.8BV / h, and the direction is up and down. Wash with 4BV pure water at a flow rate of 0.2BV / h, in the direction of up and down. Desorb with 60% ethanol again, consumption 1.5BV, flow velocity 0.4BV / h, direction goes up and down goes out, obtains refined liquid 2474.75g, the refined liquid was 7.92. Concentrate the refined solution at 40°C to 65, obtain 245.2g safflower yellow pigment paste.

[0032] Extraction and deodorization process: use ethyl acetate to deodorize the obtained safflower yellow pigment paste. The temp...

Embodiment 2

[0036] This embodiment provides a method for preparing deodorized safflower yellow, the specific operations are:

[0037] Take 1kg of safflower raw material, add 15L of 35-40°C deionized water at a ratio of 1:15, heat and extract twice at 35-40°C, and filter the extract with a 200-mesh nylon filter to obtain 22kg of filtrate. It is 0.9, refined with 1000ml of D101 macroporous adsorption resin, the adsorption capacity is 22BV, the adsorption flow rate is 1BV / h, and the direction is up and down. Wash with 5BV pure water at a flow rate of 0.5BV / h, in the direction of up and down. Then desorb with 60% ethanol, the consumption is 2BV, the flow velocity is 0.5BV / h, the direction goes up and down, and the refined solution is obtained 2118.5g. is 8.5. Concentrate the refined solution at 50°C to 50, obtain 312.55g safflower yellow pigment paste.

[0038] Extraction and deodorization process: use a mixed solvent of ethyl acetate and n-hexane (the volume ratio of n-hexane and ethy...

Embodiment 3

[0042] This embodiment provides a method for preparing deodorized safflower yellow, the specific operations are:

[0043] Take 1kg of safflower raw material, add 17L of deionized water according to the ratio of 1:17, the temperature is 40-45°C, keep warm and extract twice at 40-45°C, filter the extract with a 200-mesh nylon filter to obtain the filtrate, and obtain the filtrate 26kg, filtrate It is 0.77, and it is refined with 1000ml of LSA-10 macroporous adsorption resin; the adsorption capacity is 26BV, the adsorption flow rate is 1.2BV / h, and the direction is up and down. Wash with 6BV of pure water at a flow rate of 0.8BV / h, up and down. Then use 60% ethanol for desorption, the dosage is 2.5BV, the flow rate is 0.6BV / h, and the direction is up and down. Obtain refined liquid 2016.6g, refined liquid is 9.2. Concentrate the refined solution at 65°C to For 43, obtain 348.82g safflower yellow pigment paste.

[0044] Extraction and deodorization process: n-hexane deodo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com