Processing method of bearing pile composite foundation structure via backfilling disposing reinforcement module

A technology of composite foundation and treatment method, which is applied in the field of backfilling and placing reinforced modular pressure-bearing piles in the field of composite foundation structure treatment, can solve the problems of high construction cost, long construction period, large post-construction settlement, etc., so as to reduce construction cost and improve Construction efficiency, the effect of reducing the construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

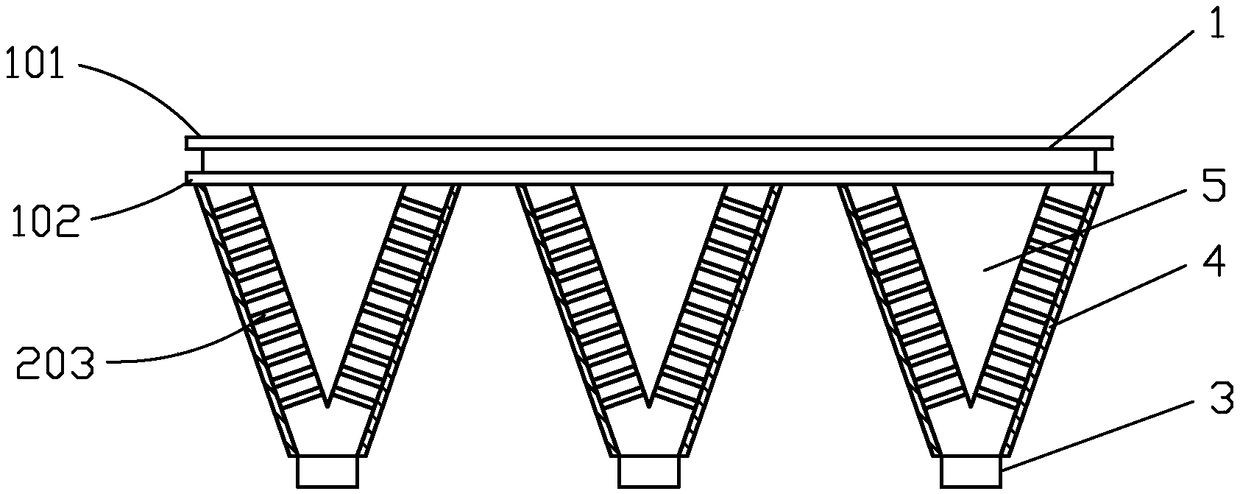

[0156] The treatment method of backfilling and placing reinforced module pressure-bearing pile composite foundation structure is as follows:

[0157] 1) Reference Figure 28 , Use a hoist 18 to hoist the modular soil pressure forming device 19 to the current construction area.

[0158] 2) Reference Figure 29 , The modular soil pressure forming device 19 applies vibration pressure to the soil, and the self-weight of the modular soil pressure forming device 19 applies longitudinal static pressure to the soil; the impact hammer 13 applies longitudinal impact to the soil The vibration device 15 causes the device 19 to vibrate, and then applies high-frequency lateral pressure to the soil; the above three combined forces act on the soil to fully compress the soil, and the moisture in the soil is reinforced The body 5, the filter device 4 and the water guiding channel 203 on the convex body reach the water collection chamber 5, and then are drawn out through the pumping pipe 10. The pum...

Embodiment 2

[0164] Reference Figure 32 , The treatment method of backfilling and placing reinforced module pressure-bearing pile composite foundation structure is as follows:

[0165] 1) The crane hoists the modular soil pressure forming device to the current construction area.

[0166] 2) The modular soil pressure forming device performs compression, compaction, drainage and consolidation of the soil to form a pit. The bottom of the pit forms a shaped soil structure corresponding to the shape of the pressure forming module.

[0167] 3) The crane hoists the modular soil pressure forming device to the next construction area, and repeat step 2) until all construction areas are processed.

[0168] 4) Backfill a layer of sand and gravel aggregate 43-2 in the forming pit, then set up a filter device 65 with water filtration and circulating purification functions, and then lay sand and gravel aggregate 43-2 until the pit is filled, and 0.8~1M above the ground.

[0169] 5) Reshape and compact the backfi...

Embodiment 3

[0171] The treatment method of backfilling and placing reinforced module pressure-bearing pile composite foundation structure is as follows:

[0172] 1) Reference Figure 33 , The crane hoists the modular soil pressure forming device to the current construction area.

[0173] 2) The modular soil pressure forming device performs compression, compaction, drainage and consolidation of the soil to form a pit. The bottom of the pit forms a shaped soil structure corresponding to the shape of the pressure forming module.

[0174] 3) Cement concrete 66 is backfilled in the forming pit and vibrated with a vibrator to improve the density. The connecting member 52 is buried when the concrete is in a fluid state. The connecting member 52 is used to connect upper devices, such as light rails, iron towers, wind energy or solar energy devices, and the like.

[0175] 4) The crane hoists the modular soil pressure forming device to the next construction area, and repeat steps 2) and 3) until all const...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com