Gas magnet mixed ball hinge joint and assembly method in use

A gas-magnetic hybrid, ball joint technology, applied in shafts and bearings, mechanical equipment, pivots and other directions, can solve the problem of air-floating ball joints relying on gravity preload and other problems, achieve mature processing technology, convenient manufacturing, and expand the scope of application Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with accompanying drawing.

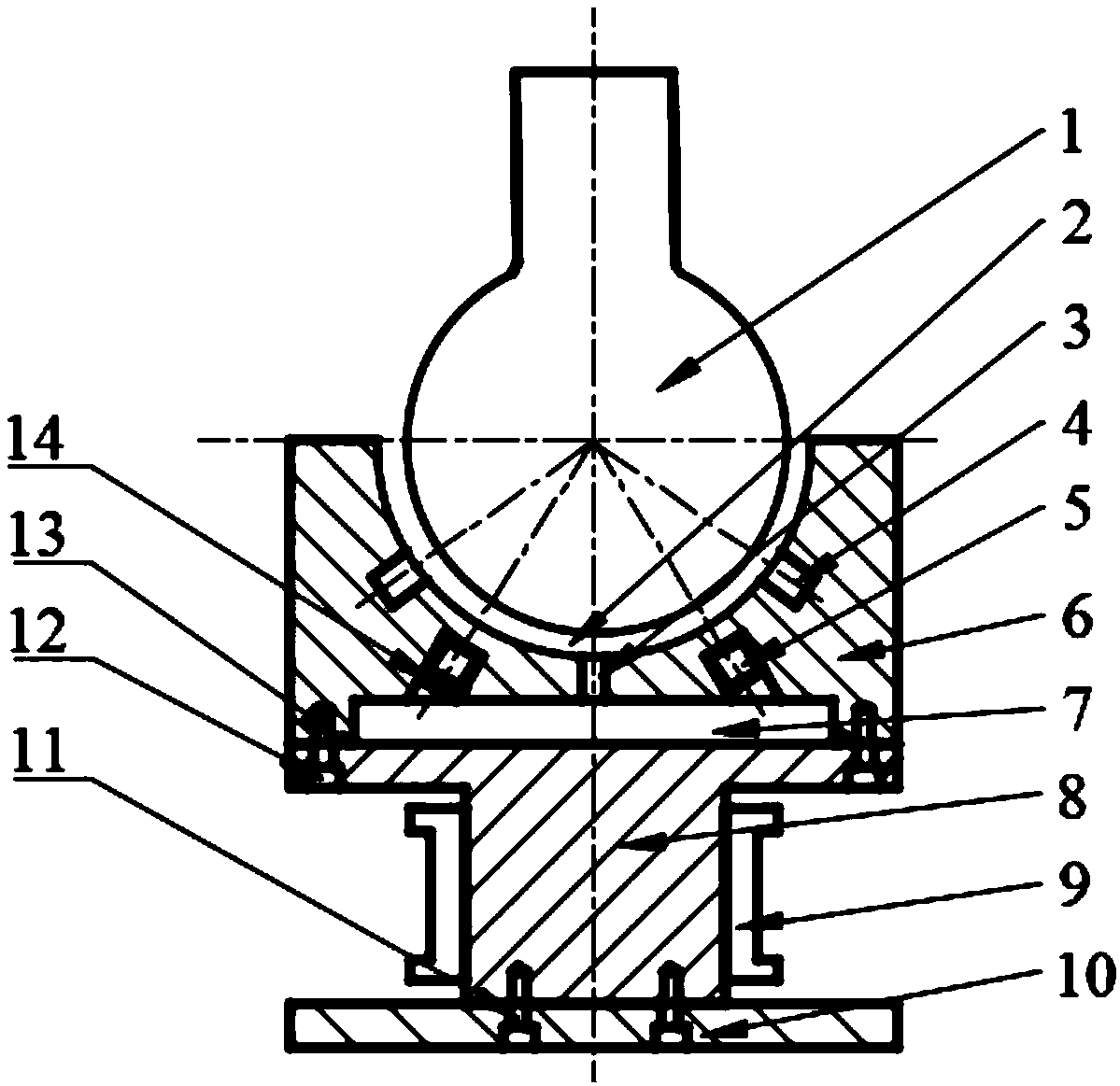

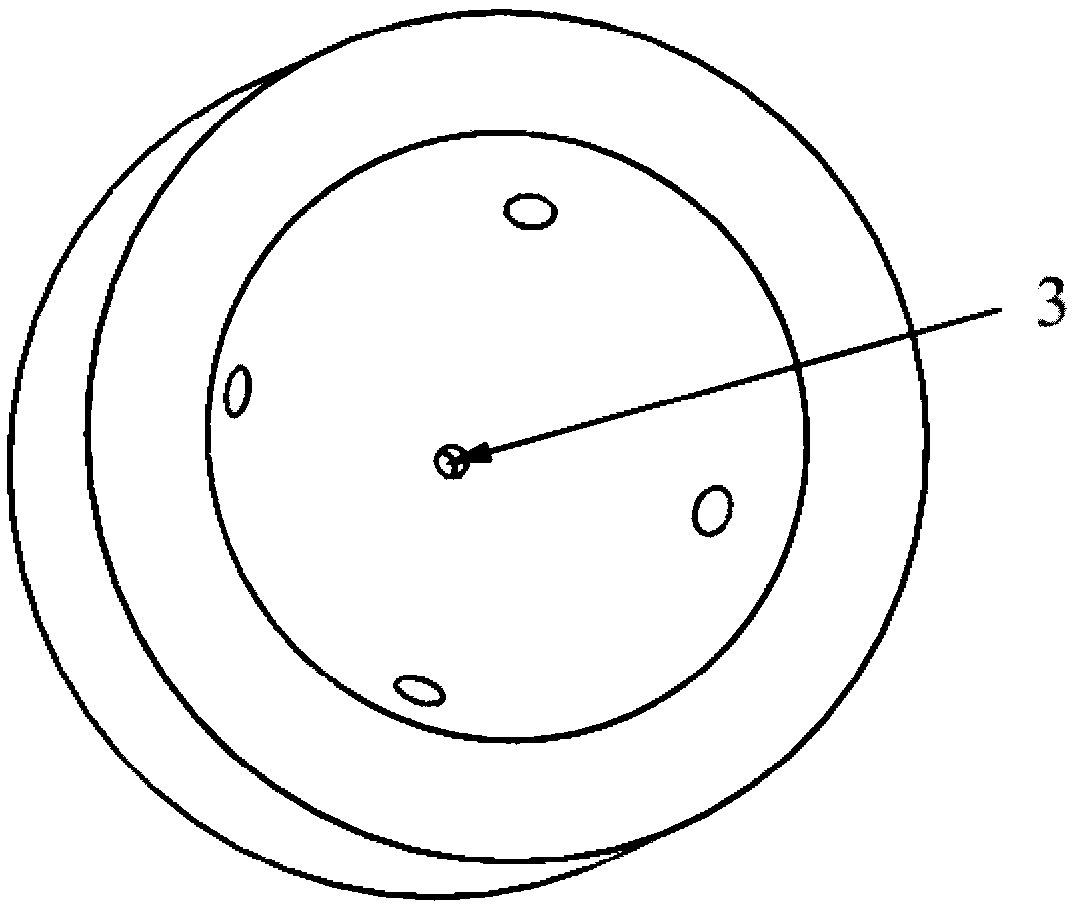

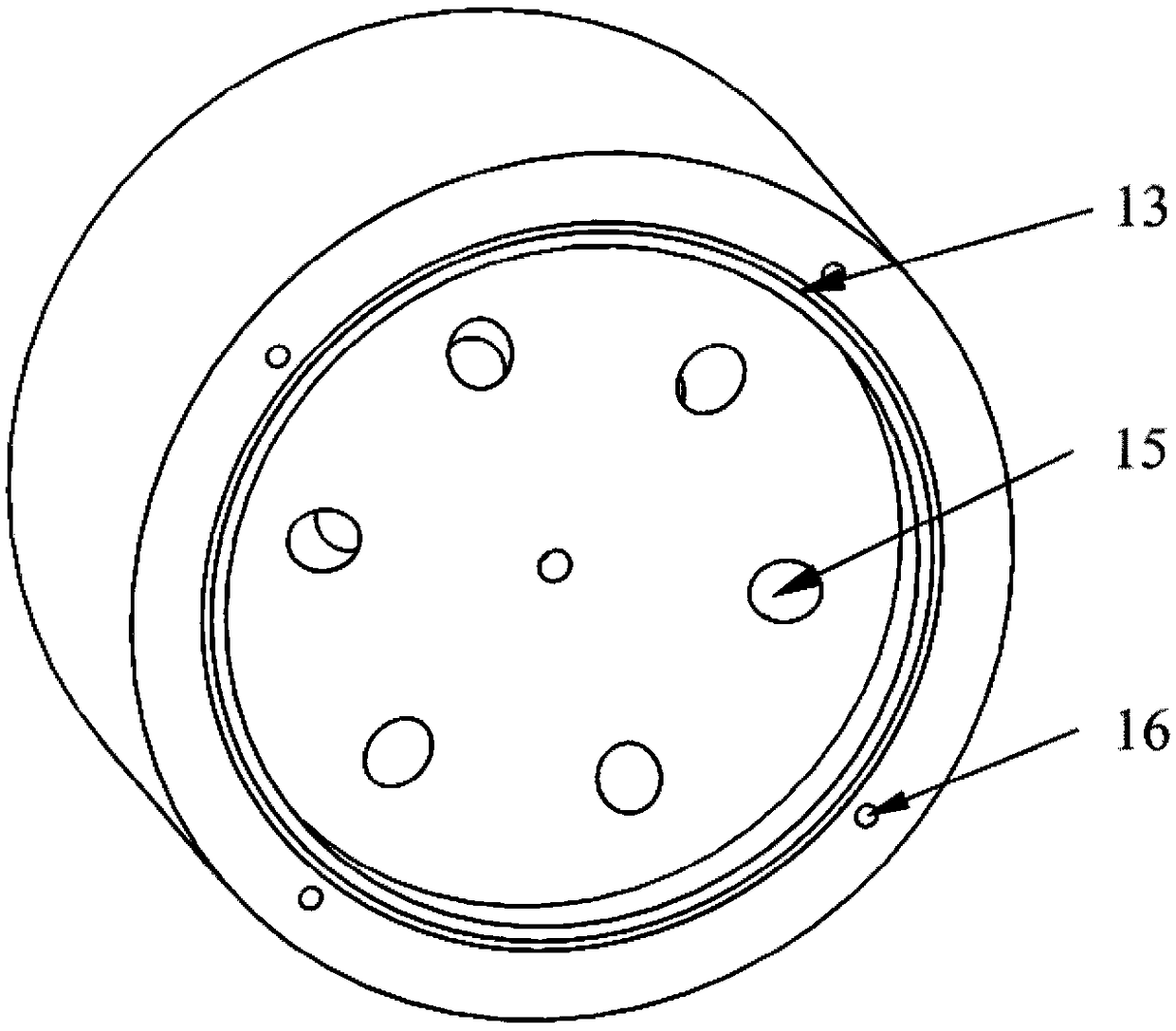

[0032] like figure 1 , 2, 3, 4, 5 and 6, the aeromagnetic hybrid ball joint includes a ball head 1, a ball socket 6, a support rod 8, a base 10, a main excitation coil 9, an auxiliary excitation coil 5 and a displacement sensor 4. There is an air supply hole 3 in the center of the spherical surface of the ball socket 6, an air cavity 7 is opened at the bottom of the ball socket 6, and the bottom end of the air supply hole 3 communicates with the top of the air cavity 7; a displacement sensor 4; in the present embodiment, the central axis of the installation hole of the displacement sensor 4 forms an included angle of 35.28° with the plane perpendicular to the central axis of the support rod 8; Excitation coil installation groove 15, the top of auxiliary excitation coil installation groove 15 is closed and set, and auxiliary excitation coil 5 is fixed in each auxiliary exc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com