Liner tube for inlet channel of plate heat exchanger

A technology for plate heat exchangers and access channels, which can be applied to heat exchange equipment, heat exchanger shells, indirect heat exchangers, etc., and can solve problems affecting the performance of coolers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

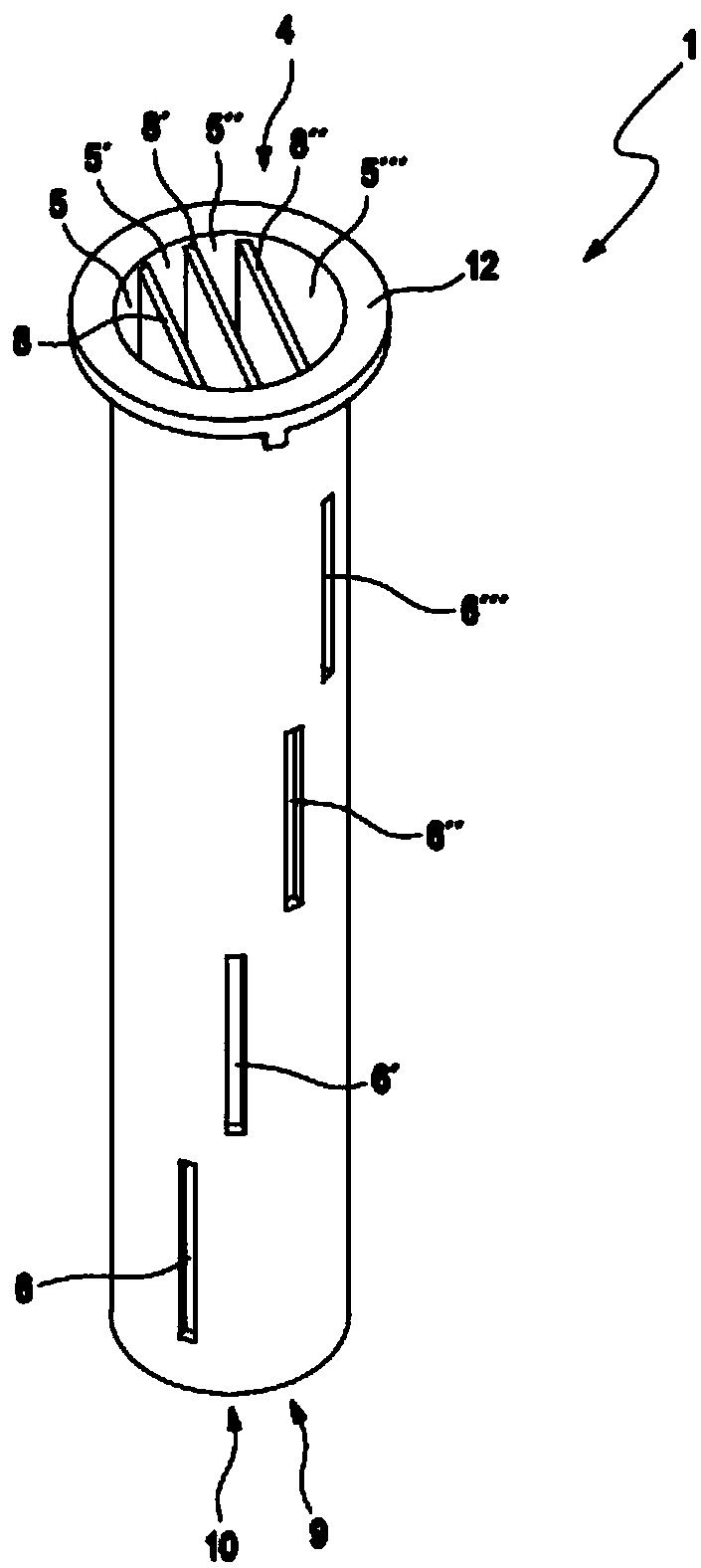

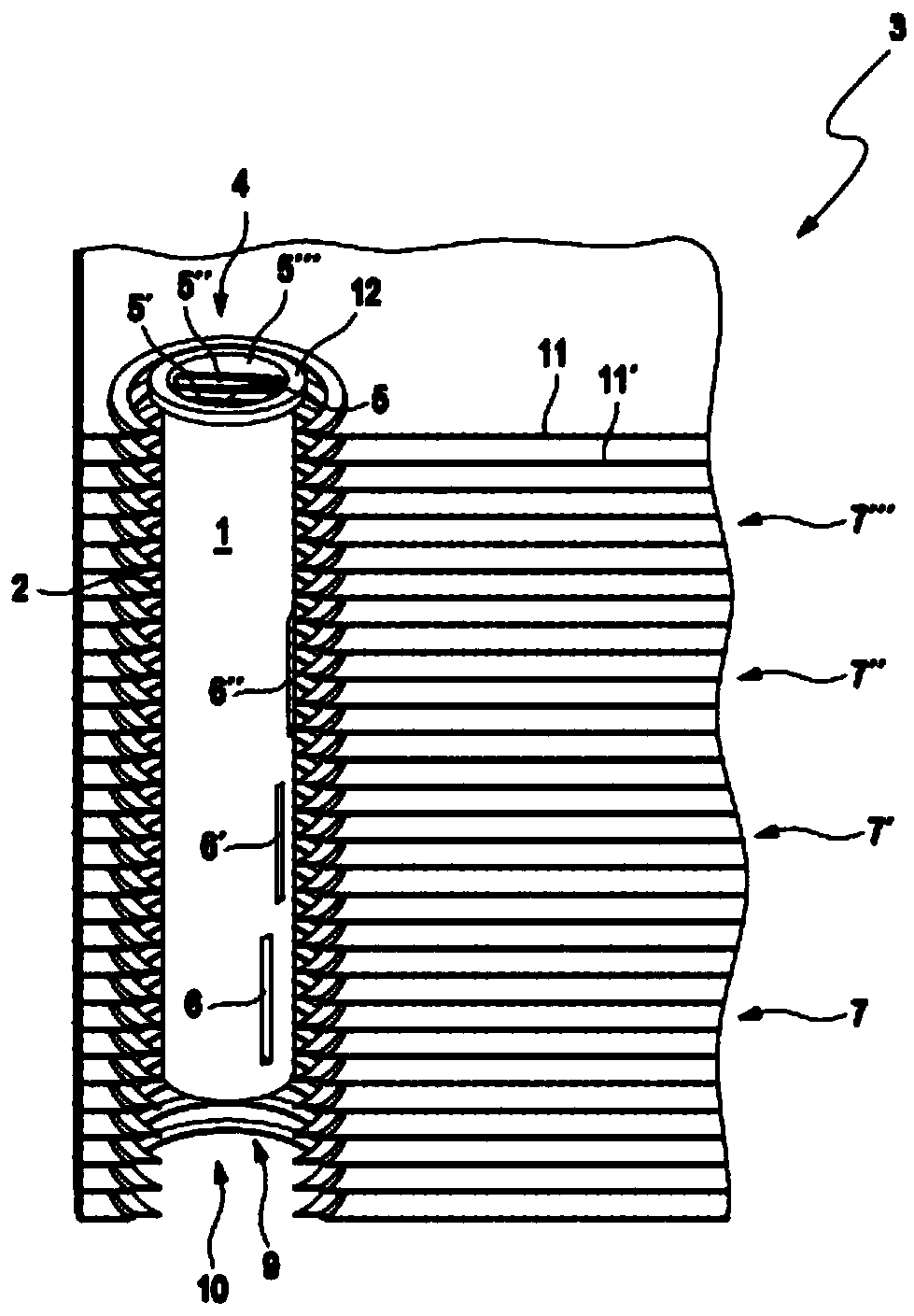

[0024] figure 1 A perspective view of a liner 1 according to the invention is shown from above at an angle onto its front open side 4 . The interior of the liner 1 is divided over its length into a total of four chambers 5, 5', 5" and 5"' by three secant partition walls 8, 8' and 8", wherein the lower end of the liner 1 is Closed, therefore closed on its rear side 10, except for the discharge opening 9 (not visible) communicating with the respective chambers 5, 5', 5" and 5"'. At different positions in relation to the chambers , the liner 1 has slit-like openings 6, 6', 6" and 6"', through which openings can be stacked on the corresponding plates 7, 7', 7" and 7"' ( figure 2 shown) distributes the refrigerant entering on its front open side 4. Thus, the flange section 12 formed on the front opening side 4 of the liner 1 is designed in such a way that the refrigerant mass flow is in the longitudinal direction of the individual chambers 5, 5', 5" and 5"' Oriented so as to be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com