Cabin body structural component on-machine rapid alignment device and alignment method based on wall thickness and shape constraint

A technology for structural parts and cabins, which is applied in the field of on-machine rapid alignment devices for cabin structural parts, can solve the problems of low alignment efficiency, low degree of automation, and insufficient precision of cabin structural parts of CNC lathes, and achieve good practical value and application prospects, high precision, and simple calculation effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] Embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0047] The present invention is based on a numerically controlled lathe, combined with the characteristics of fast measurement speed and high precision of laser sensors and ultrasonic thickness gauges, and then designing supporting fixtures to realize fast alignment of cabin parts on the machine; in addition, the compiled algorithm performs the measurement data processing, and accurately calculate the real-time adjustment of each jaw, which can effectively improve the accuracy of on-machine alignment.

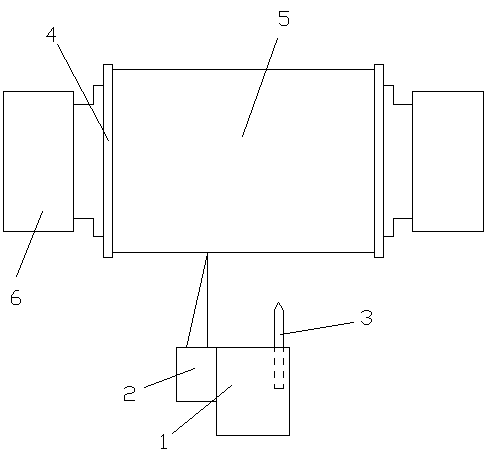

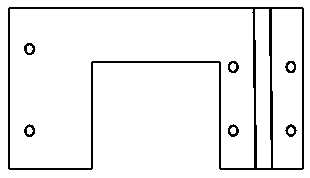

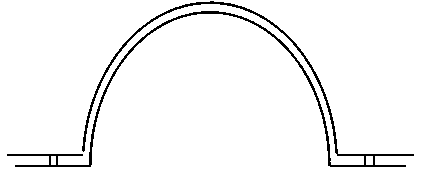

[0048] The on-board rapid alignment device for cabin structural parts based on wall thickness and shape constraints of the present invention includes a fixture 1, a laser displacement sensor 2 and an ultrasonic thickness gauge 3, and the laser displacement sensor 2 and the ultrasonic thickness gauge 3 are respectively fixed on On the fixture 1, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com