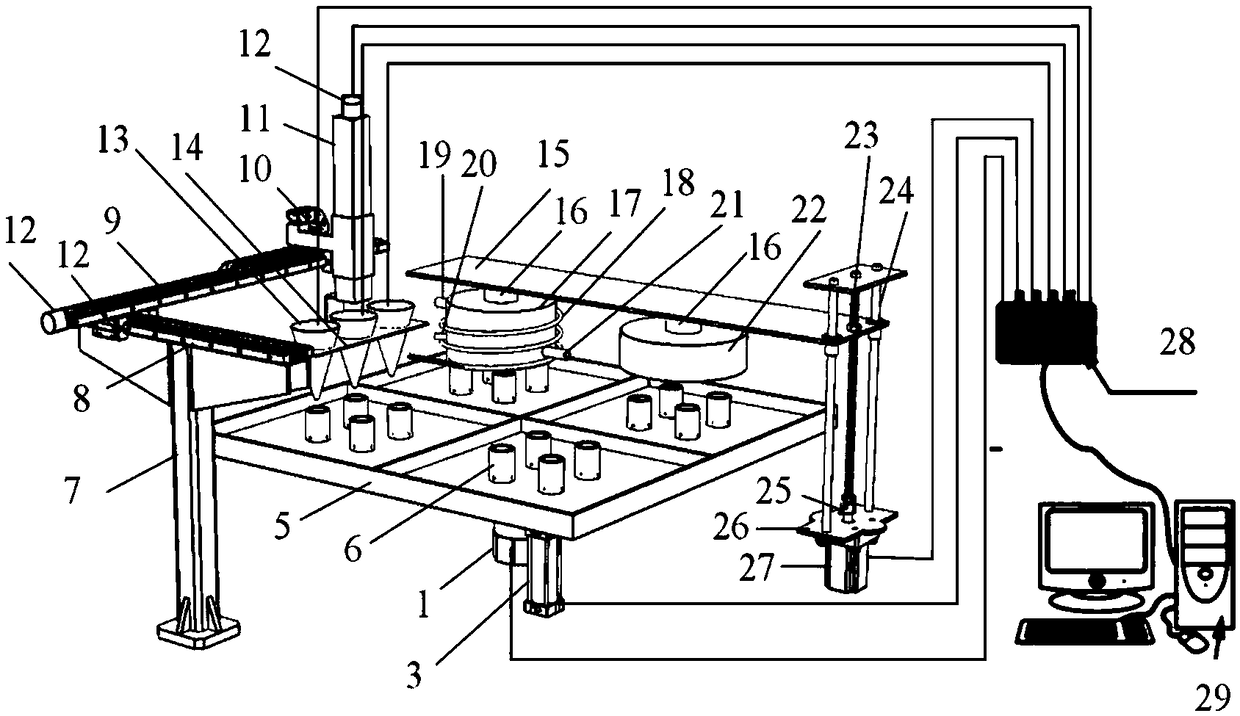

Device and method for high-throughput, continuous and rapid preparation of alloy sample

A high-throughput, alloy technology, applied in the direction of measuring devices, sampling devices, test sample preparation, etc., can solve the problems of long cycle, low efficiency, high cost, etc., to achieve reduced material consumption, strong controllability, volume small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

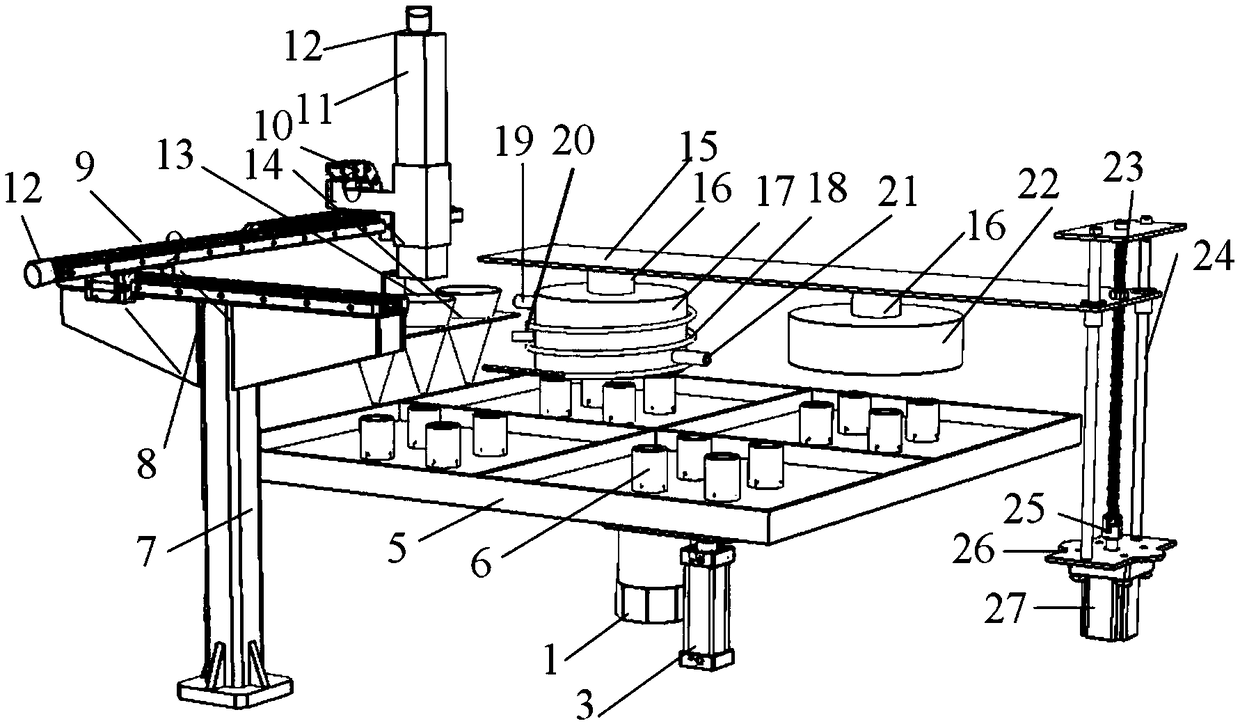

Method used

Image

Examples

preparation example Construction

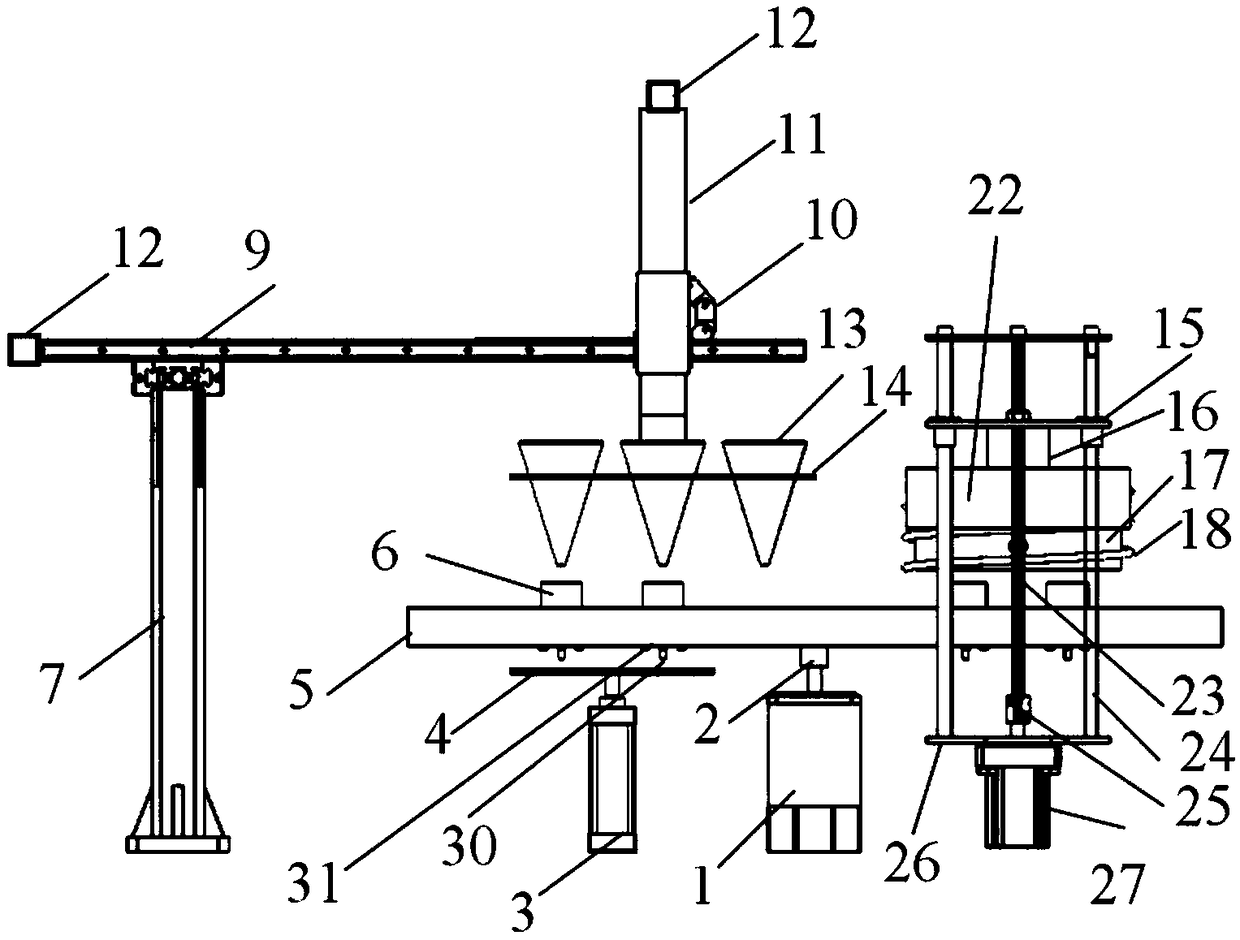

[0064] A method of preparing an alloy using the above-mentioned device, the method comprising the following steps:

[0065] Step 1: Fix a certain number of crucibles 6 on the pushable ejector pins 30 in the four areas of the turntable according to the experimental requirements;

[0066] Step 2: put different high-purity metals into independent stockers 13 according to the target alloys, input the content and composition ratio of the target alloys that need to be put into each crucible 6 in the computer 29 of the PLC control system 28, and automatically calculate Addition of each metal element in each crucible 6;

[0067] Step 3: Controlled by the PLC control system 28, the stocker 13 on the support table 14 is moved by the manipulator to complete the ratio of alloying elements in each crucible 6 in the batching area;

[0068] Step 4: After the batching process in the batching area is completed, the PLC control system 28 controls the rotating table 5 to rotate 90° clockwise, s...

Embodiment 1

[0073] Taking the preparation of Al(80-x)Zn20Mgx (0≤x≤10, x=0, 0.1, 0.2, 0.3...10) aluminum alloy with a total of 101 components as an example, a total of 16 crucibles with a size of Φ3cm×4cm were taken. Four crucibles are respectively placed in the pre-designed positions of the batching area, heating and melting area, cooling and solidification area and sampling area of the turntable, and are connected by nuts; the shape and size of the turntable is 400mm×400mm×10mm; the bottom of the crucible can be pushed The rod passes through the through hole of the turntable and extends to 50mm from the bottom of the turntable;

[0074] Put Al (7kg), Zn (3.5kg) and Mg particles (0.5kg) with a particle size of 1mm into three separate stockers, and input the number of crucibles and the content of the target alloy in the crucible into the computer system and composition ratio, automatically calculate the amount of metal elements added in each crucible;

[0075] After the experiment start...

Embodiment 2

[0082] To prepare Mg(95-x)Sn3Zn2Alx (0≤x≤30, x=0,0.05,0.10,0.15,0.20,

[0083] ... 30) Taking a magnesium alloy with a total of 601 components as an example, a total of 36 crucibles with a size of Φ2cm×2cm were taken and placed in the pre-designed positions of the batching area, heating and melting area, cooling and solidification area and sampling area of the turntable with 3 9 crucibles are placed in a ×3 array and connected by nuts; the shape and size of the turntable is Φ500mm×12mm; the pushable ejector pin at the bottom of the crucible passes through the through hole of the turntable and extends to 25mm from the bottom surface of the turntable;

[0084] Put Mg (4.2kg), Sn (0.5kg), Zn (0.4kg) and Al particles (1.2kg) each with a particle size of 0.5mm into four separate stockers and input them into the crucible in the computer system Quantity, content and composition ratio of the target alloy in the crucible, automatically calculate the required amount of the four metal el...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com