Capacitor Core Automatic Withstand Voltage Capacitance Testing Machine

A technology for capacitance testing and capacitors, which is used in capacitance measurement, dielectric strength testing, resistance/reactance/impedance measurement, etc. It can solve the problems of inaccurate test position, bulky capacitor core, and low production efficiency, so as to prevent electric shock from being damaged. Effects of electric shock or injury, precise control of production efficiency, and improvement of production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to make the object, technical solution and advantages of the present invention clearer, various embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

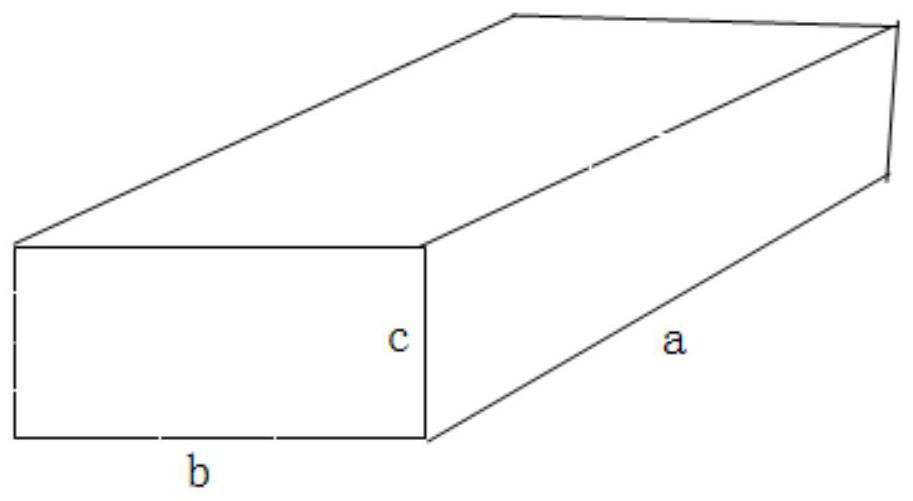

[0029] Such as figure 1 As shown, the size of the capacitor core is: a*b*c=322mm*(125mm or 165mm)*(334mm or 165mm), the maximum weight of the product is 75kg, and the height of the track platform is 750mm.

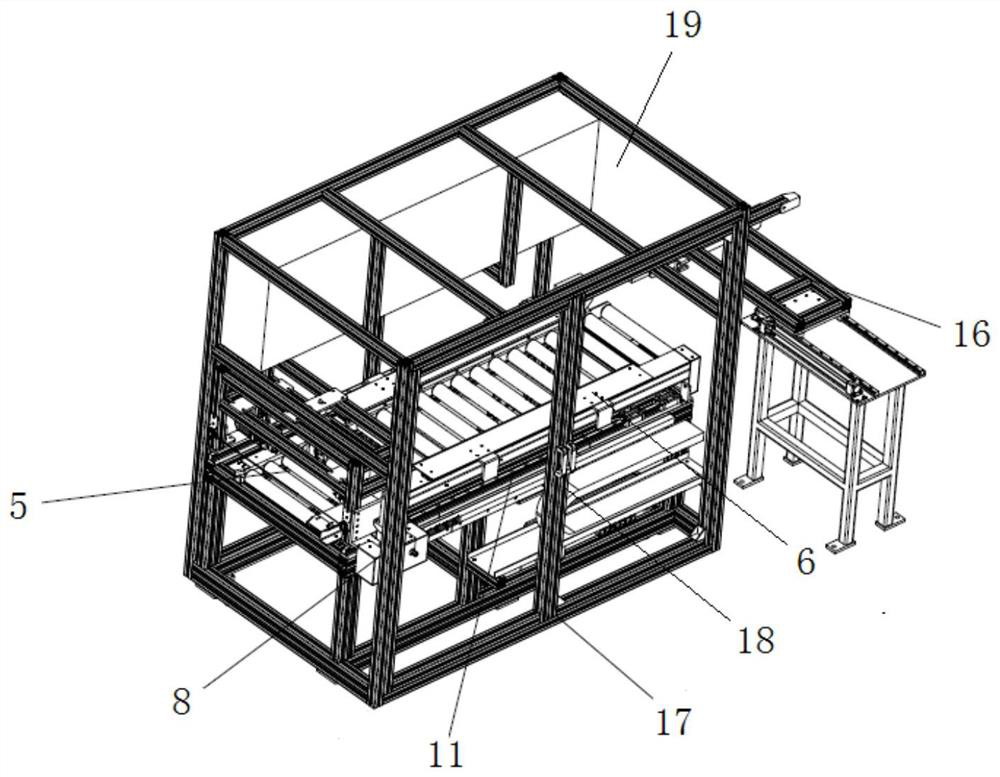

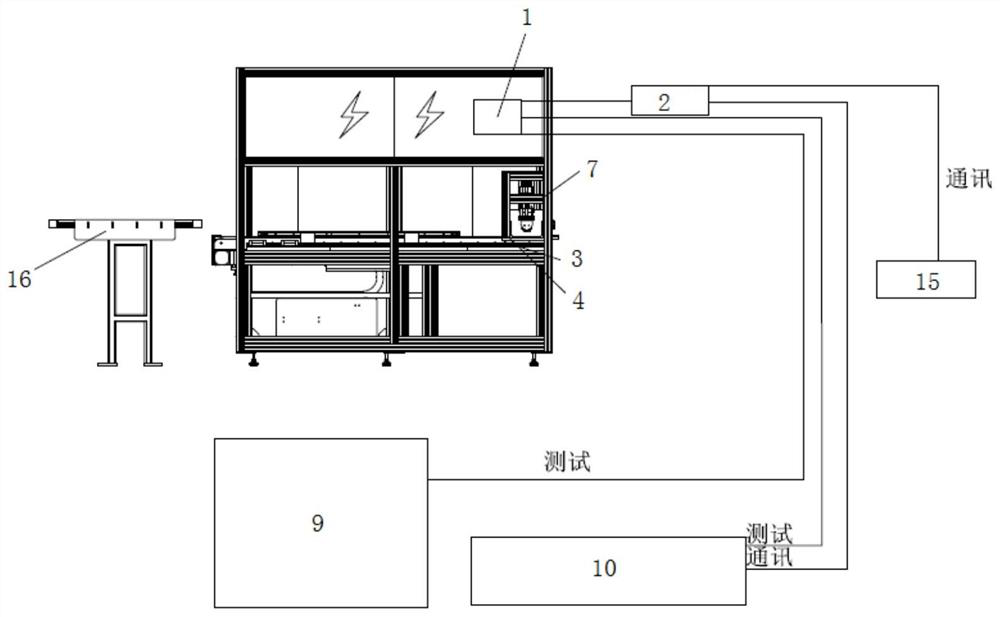

[0030] Please refer to the following Figure 2 to Figure 5 As shown, a capacitor core automatic withstand voltage capacitance testing machine includes a detection system, a PLC control system 1, a host computer 2, an executive mechanism and an alarm mechanism, and the detection system, the executive mechanism and the alarm mechanism are respectively connected to the PLC control system 1, The PLC control system 1 is connected with the upper computer 2 .

[0031] The detection system includes a scanning gun, a core position sensor, a machine ori...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com