A method for manufacturing a variable array capacitor and an electromagnetic dual-touch induction panel

A manufacturing method and dual-touch technology, which are applied in electrical digital data processing, input/output process of data processing, instruments, etc., can solve the problems of thick structure, inconvenient market promotion and implementation, and high cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below with reference to the accompanying drawings and specific embodiments.

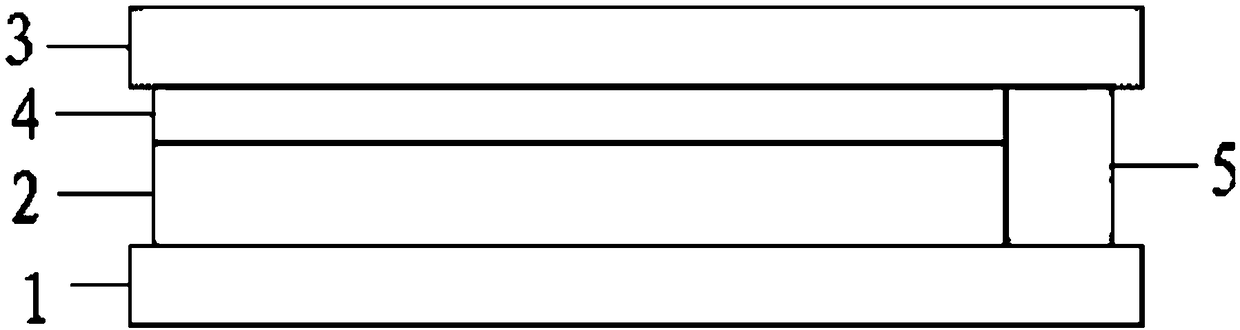

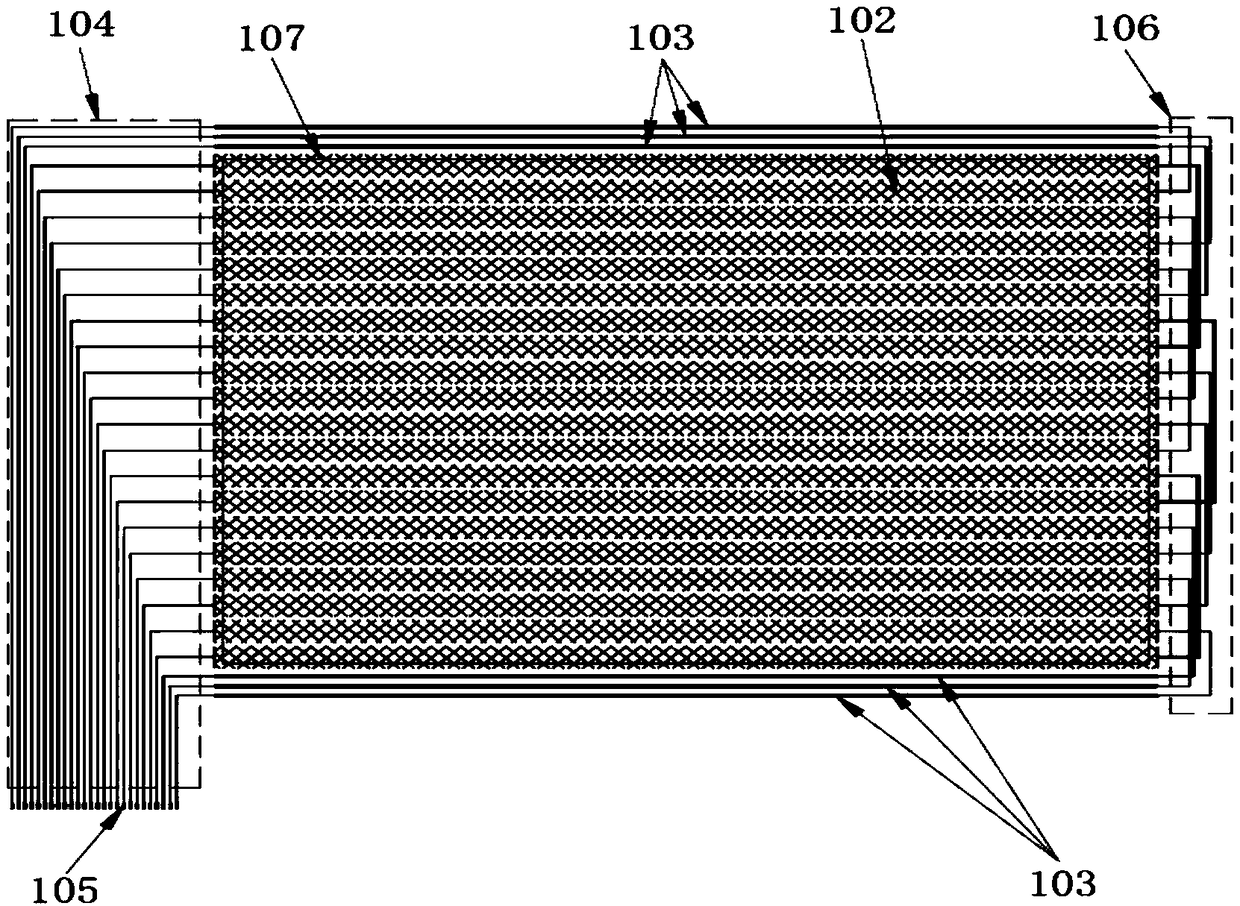

[0013] figure 1 A schematic structural diagram of a touch panel is provided for the present invention. It includes a liquid crystal module 1, a sensor 2, a cover plate 3, an optical double-sided adhesive tape 4 and a flexible circuit board 5; the liquid crystal module 1 is used for displaying images, and it includes devices such as a liquid crystal display and a display control chip. The liquid crystal display is preferably an LCD display. It has fast response speed, good contrast, high brightness, large viewing angle, and rich colors; the sensor 2 includes a conductive substrate, and a copper film is sputtered on the conductive substrate through a coating process, and the copper film is treated by yellow light. The copper film signal line is formed by the process, and the copper film signal line is processed and connected with the transparent c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com