High-performance engine cable assembly

A cable assembly and engine technology, applied in the direction of insulated cables, electrical components, cables, etc., can solve the problems of low reliability, shorten the service life of cables, and can not work normally, achieve improved reliability and mechanical strength, enhance reliability, The effect of good wear properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

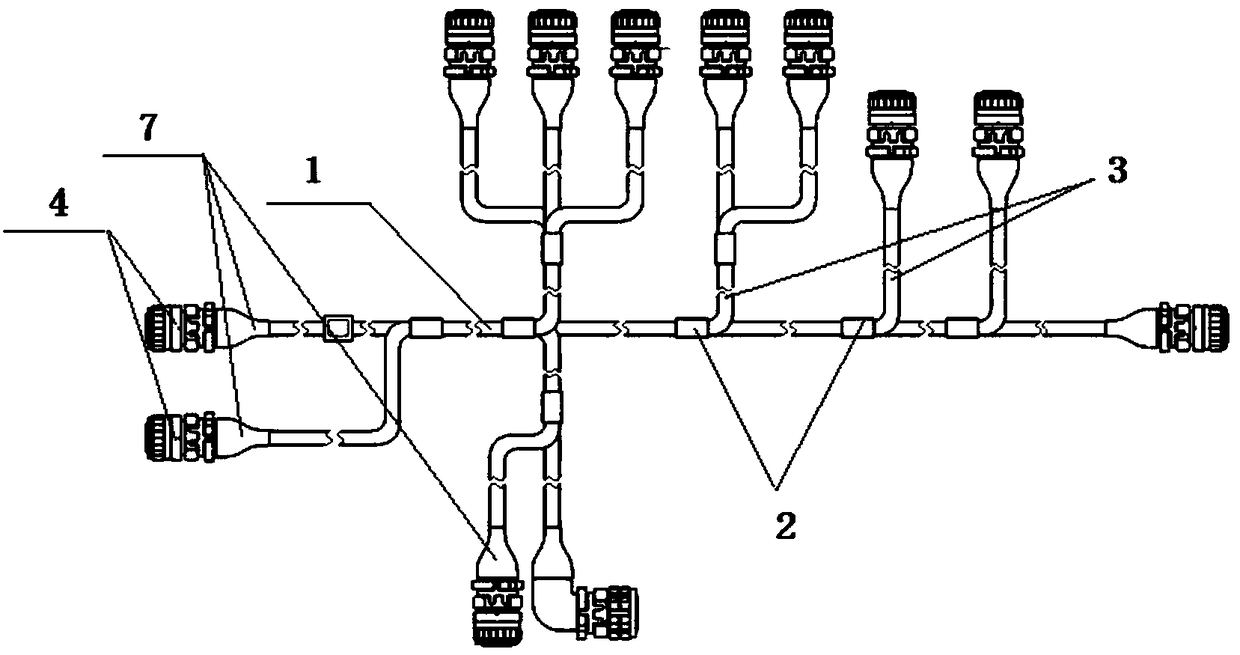

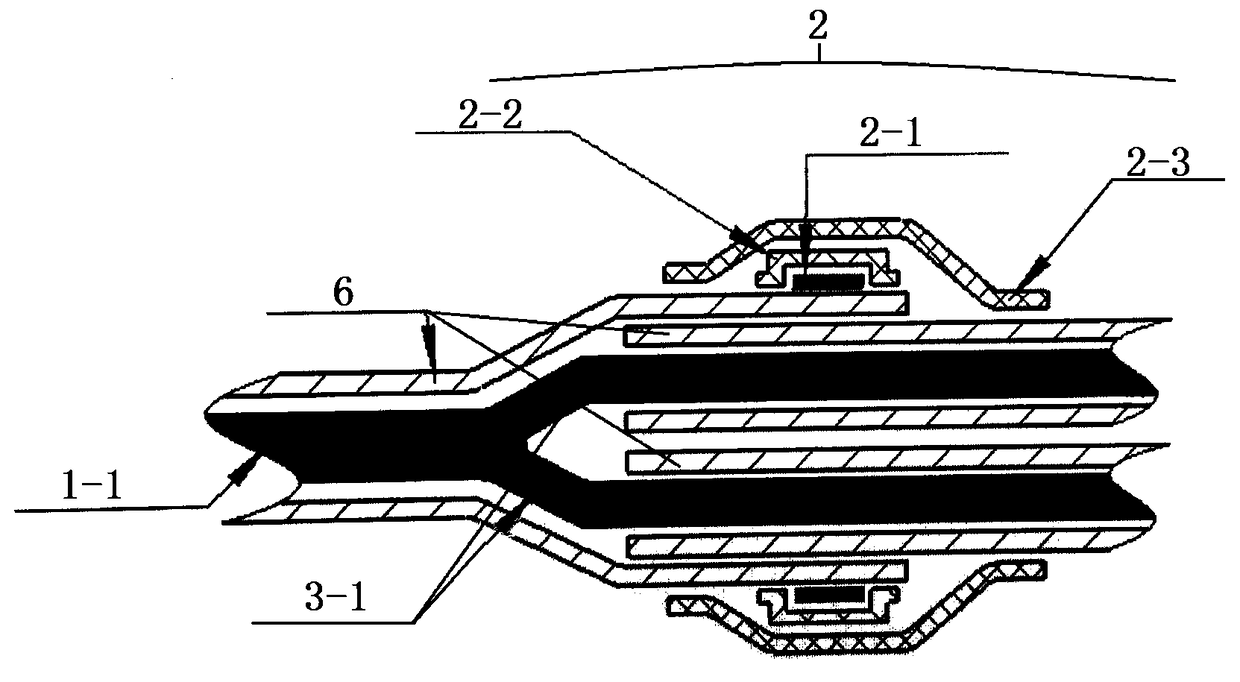

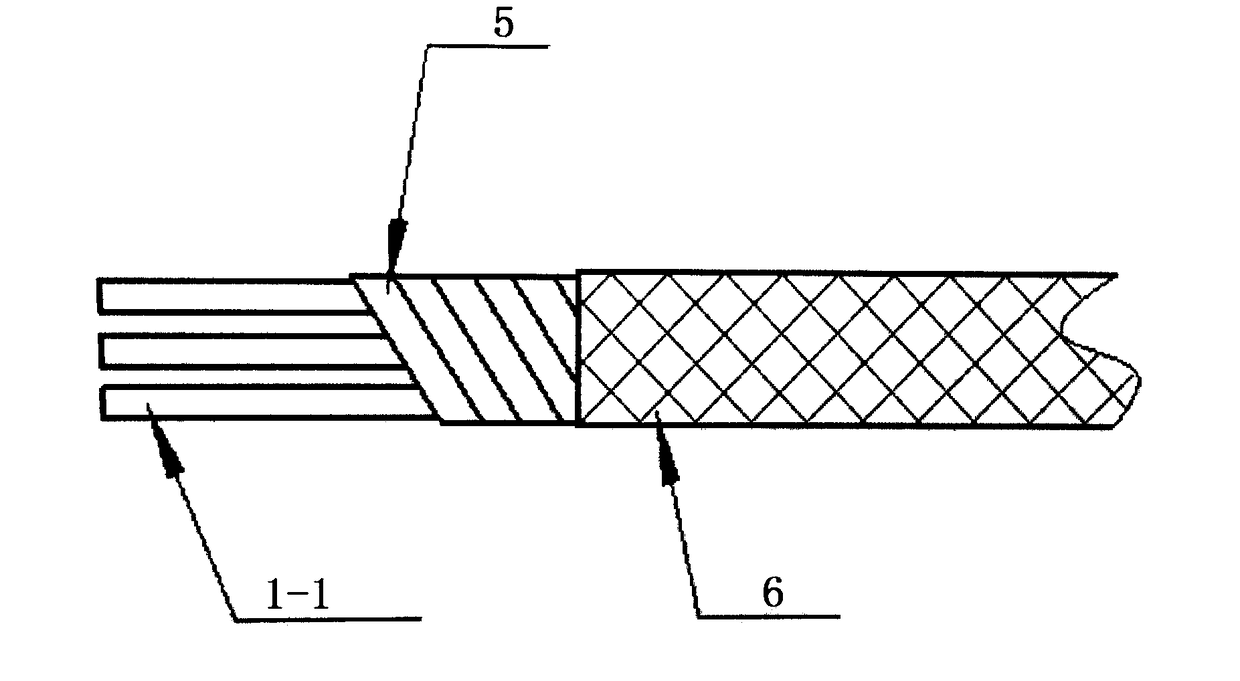

[0020] Reference Figure 1-5 , A high-performance engine cable assembly, the engine cable assembly includes a main cable, the main cable 1 is divided into a plurality of branch cables 3 by a plurality of branching assemblies 2, the two ends of the main cable 1 and the ends of the branch cable 3 are respectively installed Tail accessory 4; the main cable 1 includes a main wiring harness 1-1, and the branch cable 3 includes a branch wiring harness 3-1. Teflon film is wound on the outer periphery of the main wiring harness 1-1 and the branch wiring harness 3-1 5. An anti-wave sleeve 6 is provided on the outer circumference of the PTFE film 5, and the anti-wave sleeve 6 of the main wiring harness 1-1 is crimped on the outer circumference of the anti-wave sleeve 6 of the branch wiring harness 3-1 at the bifurcation; The bifurcation assembly 2 includes a steel cable tie 2-1, an insulating self-adhesive tape 2-2, and a heat shrinkable tube 2-3. The steel cable tie 2-1 is tied to the o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com