An electrified railway in-phase power supply and transformation system

A technology for electrified railways and substation systems, applied in flexible AC transmission systems, electrical components, circuit devices, etc., can solve problems such as the restriction of the number of traction substation groups, the limitation of electrified railway mileage, and the poor economic indicators of network loss. Superior performance, ease of implementation, and reduced power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

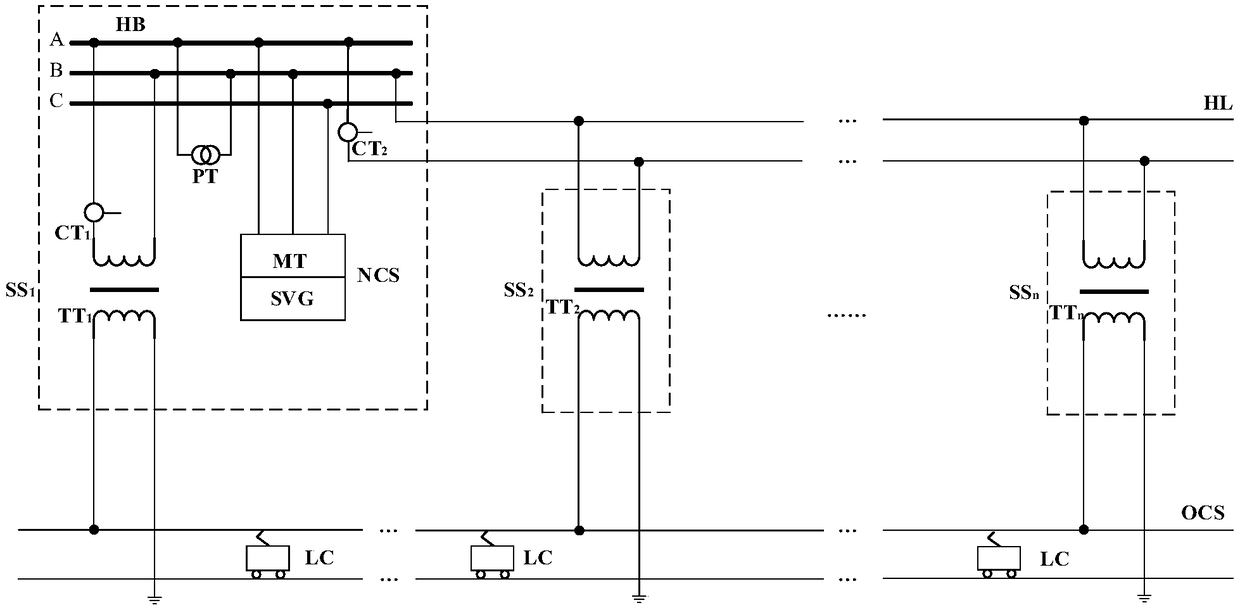

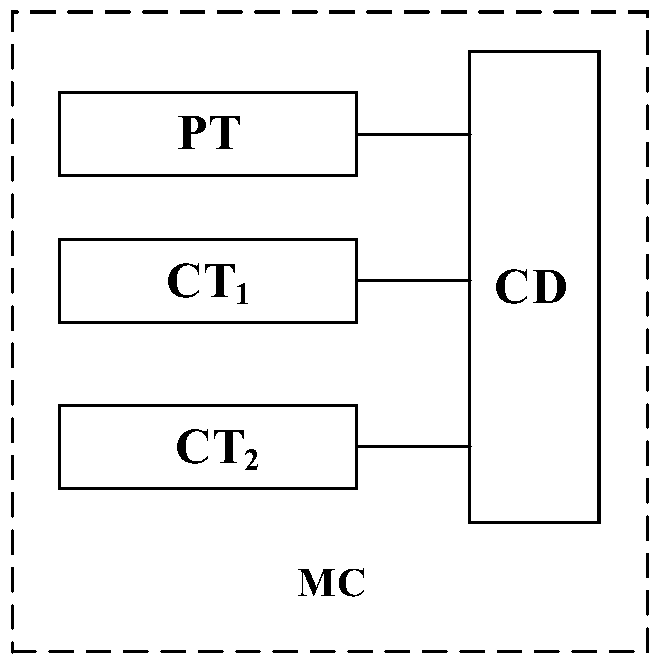

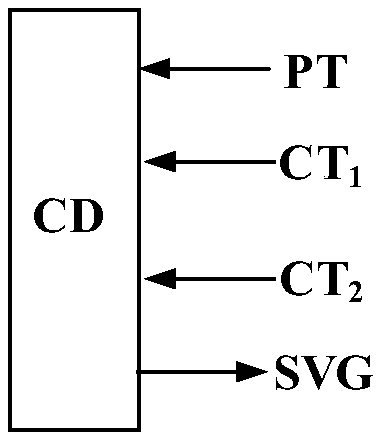

[0027] In order to better understand the creative idea of the present invention, the working principle of the present invention is: the power factor of the AC-DC train is very high, which can be considered as 1, and the power factors of each traction substation are the same, and the three-phase high-voltage bus PCC (negative sequence assessment point), the total negative sequence current generated at the PCC can be calculated with scalar algebra, and the total negative sequence current or power can be centrally compensated in a traction substation by installing a negative sequence compensation system. After compensation, it meets the national standard requirements, where Negative-sequence compensation generates negative-sequence power flow through its three-phase reactive power compensation device, which does not change the active power flow of the same-phase power supply and transformation system. Railway power supply mileage.

[0028] The present invention will be further ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com