Scanning probe microscope

A probe microscope, scanning technology, applied in the field of scanning probe microscope, can solve the problem of not necessarily obtaining the surface image of the sample, inaccuracy, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

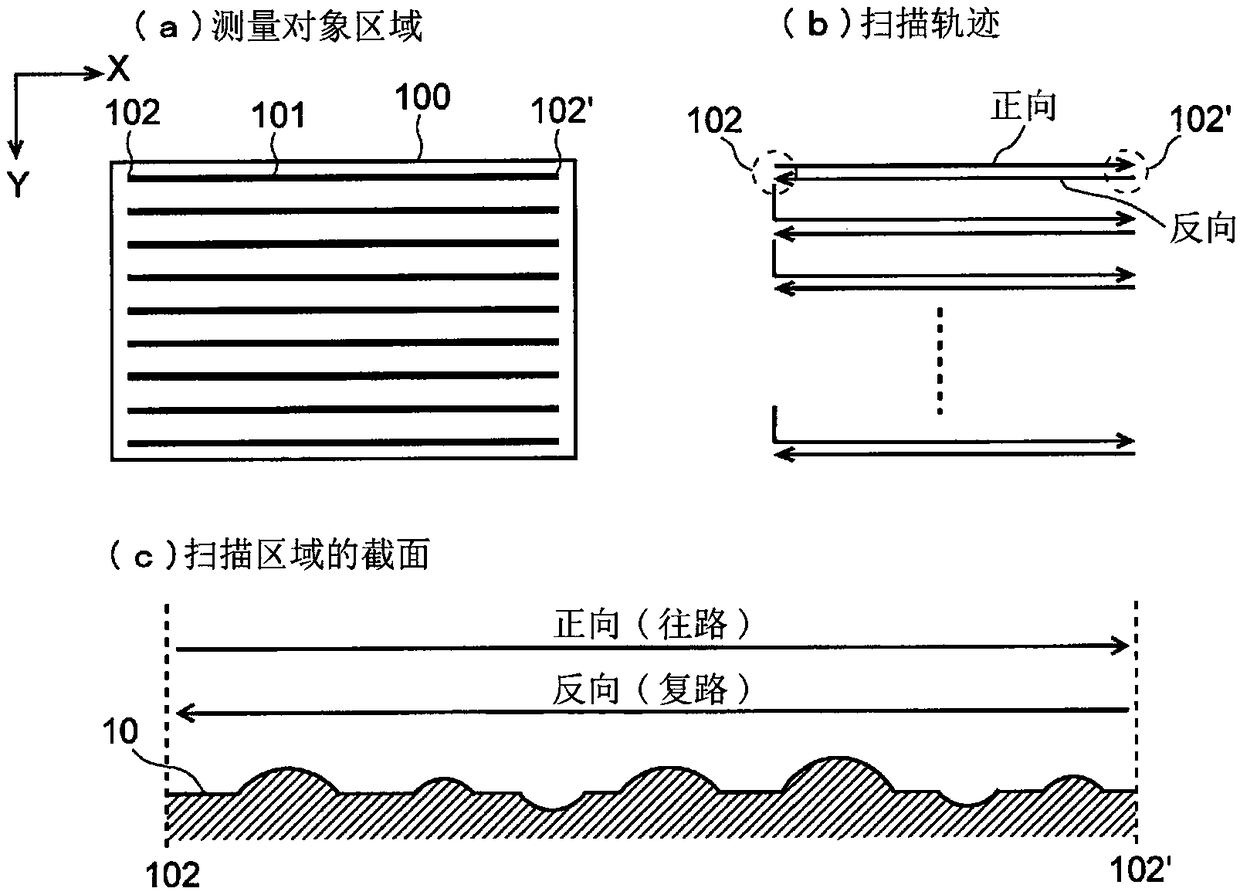

[0044] Hereinafter, a first embodiment of a scanning probe microscope (SPM) according to the present invention will be described with reference to the drawings.

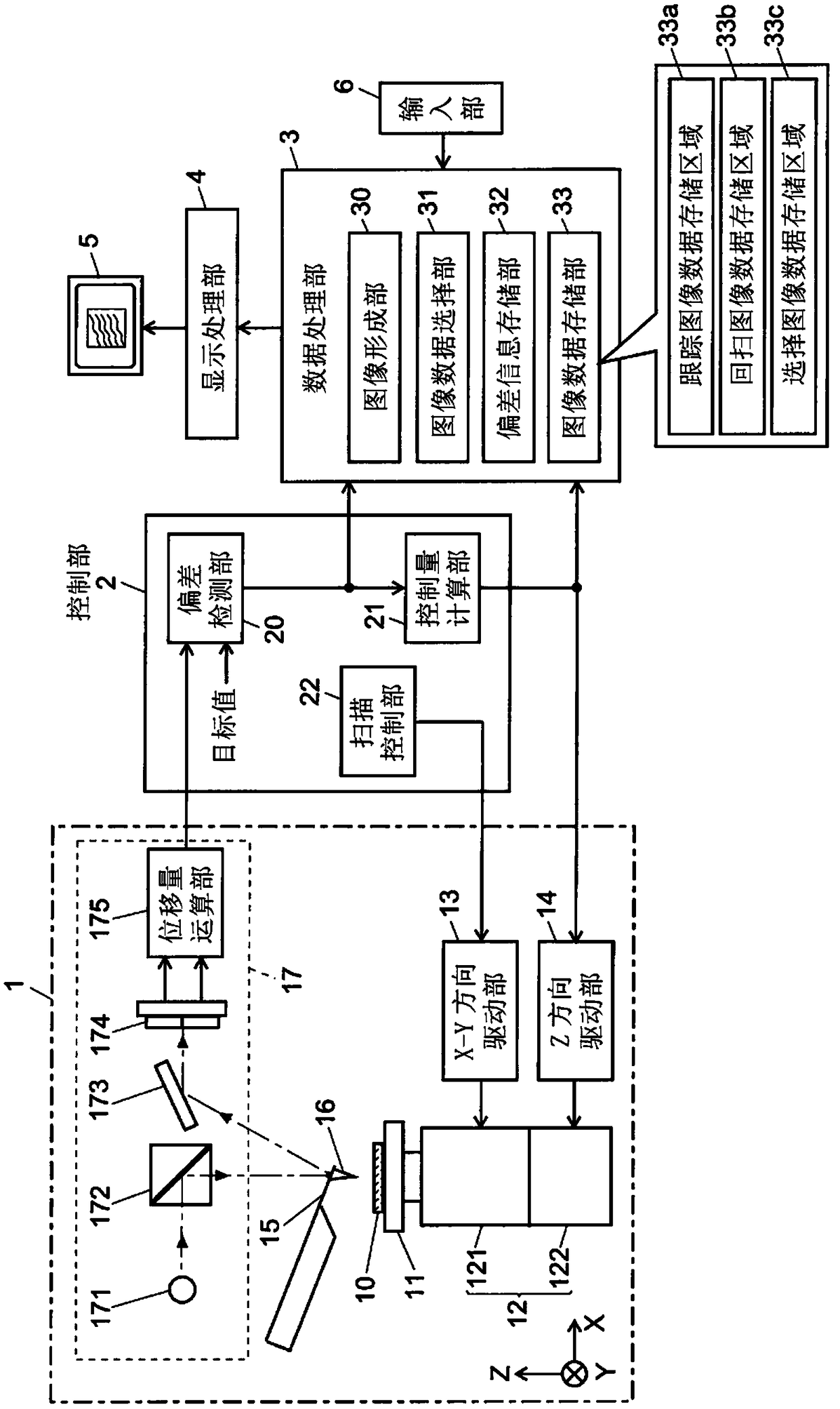

[0045] figure 1 is a structural diagram of the main part of the SPM of the first embodiment.

[0046] In the measurement unit 1 , a sample 10 to be measured is placed on a sample stage 11 provided on a scanner 12 . The scanner 12 includes an XY scanner 121 that moves the sample 10 in two axial directions of X and Y that are perpendicular to each other in a plane parallel to the upper surface of the sample stage 11, and moves the sample 10 in the direction of the X axis and the Y axis. The Z scanner 122 moves slightly in the Z-axis direction perpendicular to the Y-axis. The XY scanner 121 and the Z scanner 122 respectively use piezoelectric elements that are displaced by voltages applied from the X-Y direction driving unit 13 and the Z direction driving unit 14 as drive sources.

[0047] A flexible cantilever 15 h...

no. 2 example

[0067] Figure 5 is a structural diagram of the main part of the SPM of the second embodiment. Structural elements that are the same as or equivalent to those of the SPM of the first embodiment described above are given the same reference numerals, and description thereof will be omitted unless particularly necessary. The SPM performs sample surface shape measurements in dynamic mode. Therefore, the vibration control unit 23 drives a piezoelectric element (not shown) attached to the cantilever 15 to vibrate the cantilever 15 at a predetermined frequency. In addition, the amplitude calculation unit 24 obtains the amplitude of the vibration of the cantilever 15 during the above-mentioned excitation based on the displacement obtained by the displacement calculation unit 175 . The deviation detection unit 20 obtains a deviation between the vibration amplitude and the target amplitude value, and performs feedback control so that the deviation becomes zero.

[0068] The deviation...

no. 3 example

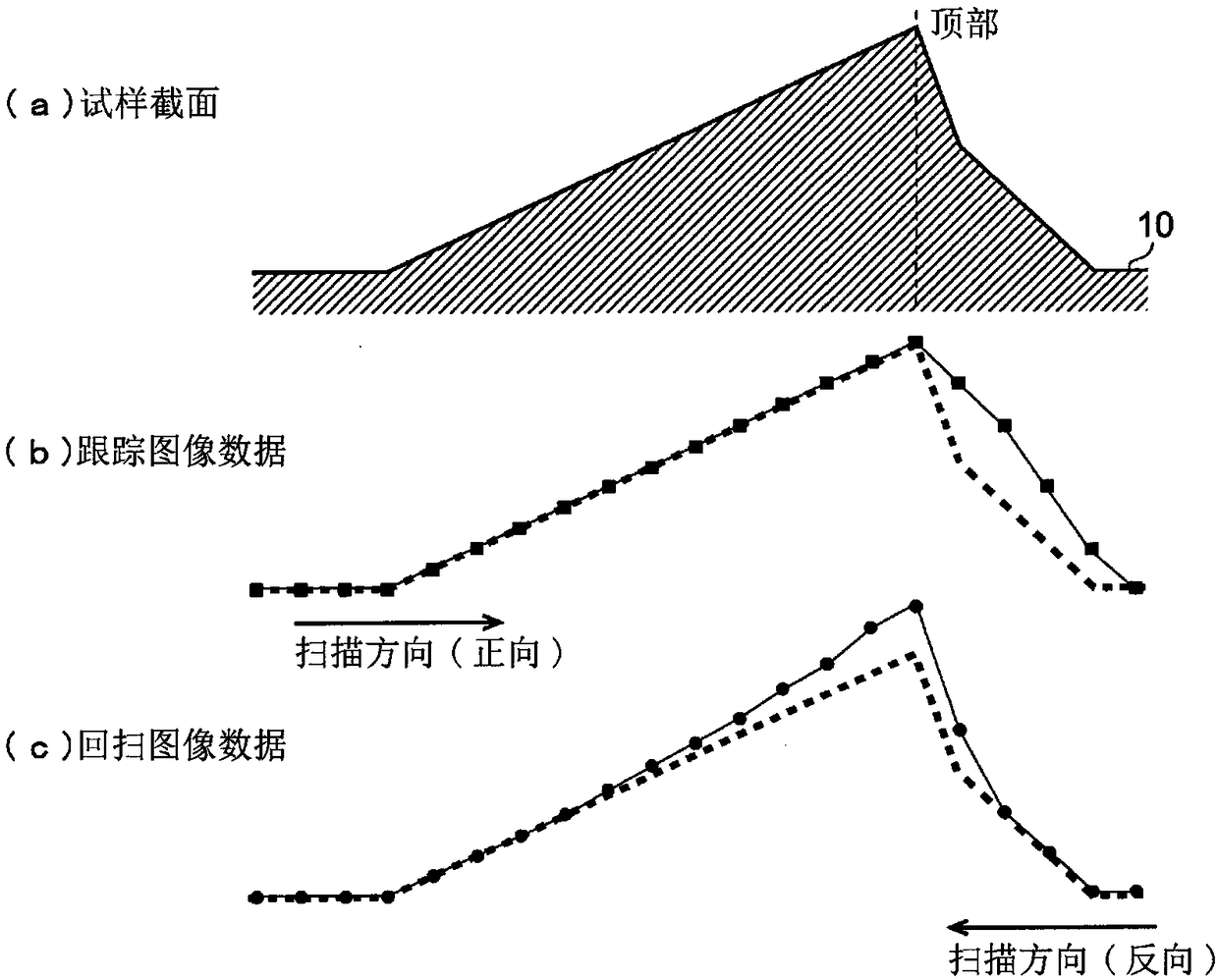

[0070] In the first embodiment and the second embodiment, in order to measure the shape of the sample surface, the selection of the tracking image data and the retrace image data is performed using the deviation obtained in the closed loop for feedback control of the Z scanner 122, but It is also possible to select highly accurate image data by using other data reflecting the physical property information of the sample surface that can be acquired by SPM instead of the deviation.

[0071] Figure 6 is a structural diagram of the main part of the SPM of the third embodiment. In this SPM, selection of image data is performed using data obtained by measurement by phase mode, and measurement by phase mode can be performed in parallel with measurement of sample surface shape by dynamic mode.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com