Hydraulic full-automatic feeding crusher and crushing method thereof

A fully automatic, crushing machine technology, applied in the direction of feed, grain processing, food science, etc., can solve the problems of low degree of automation, achieve the effect of high degree of automation, cheap price, and reduce the cost of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In order to further understand the content of the present invention, the present invention will be described in detail below in conjunction with specific examples.

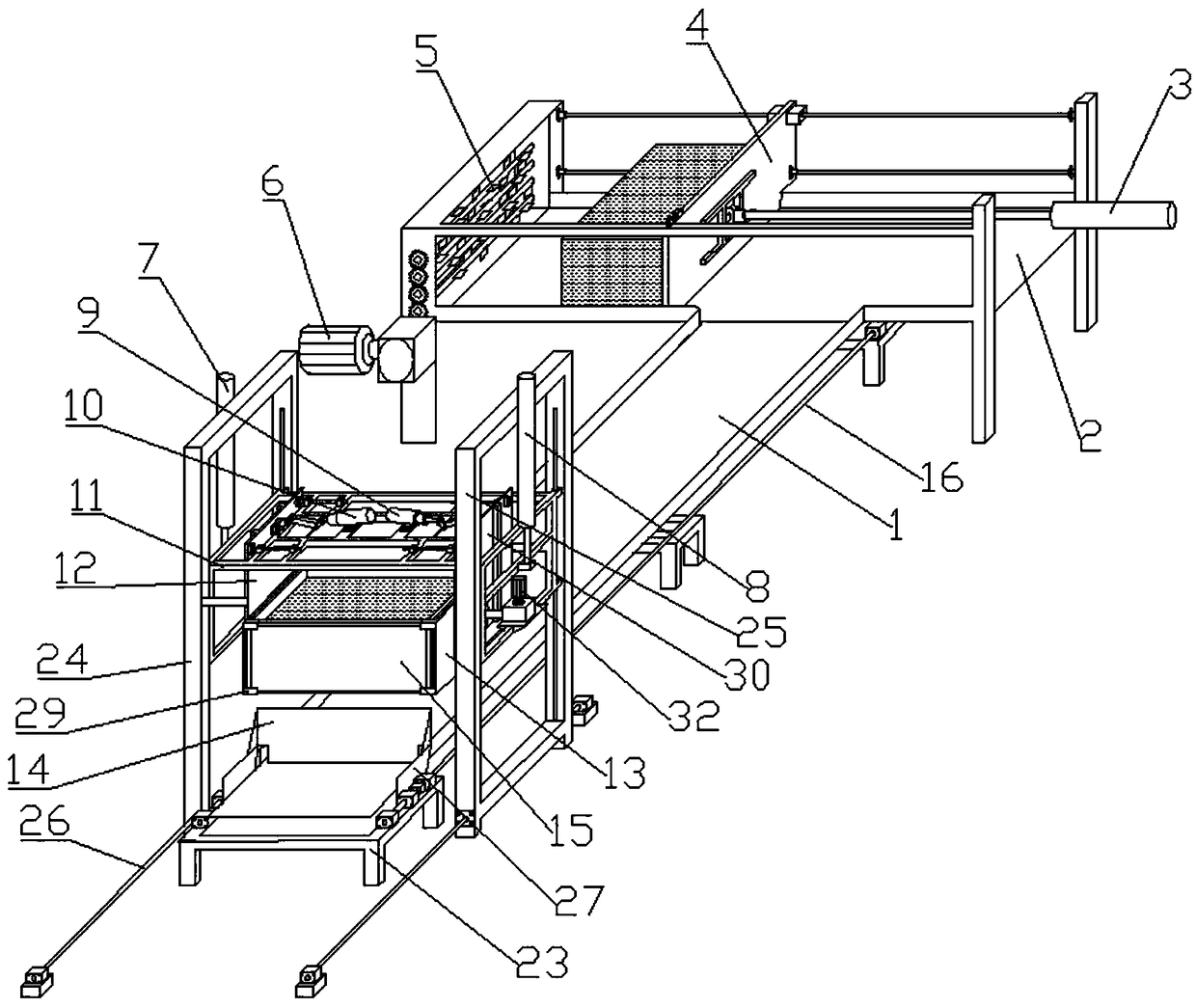

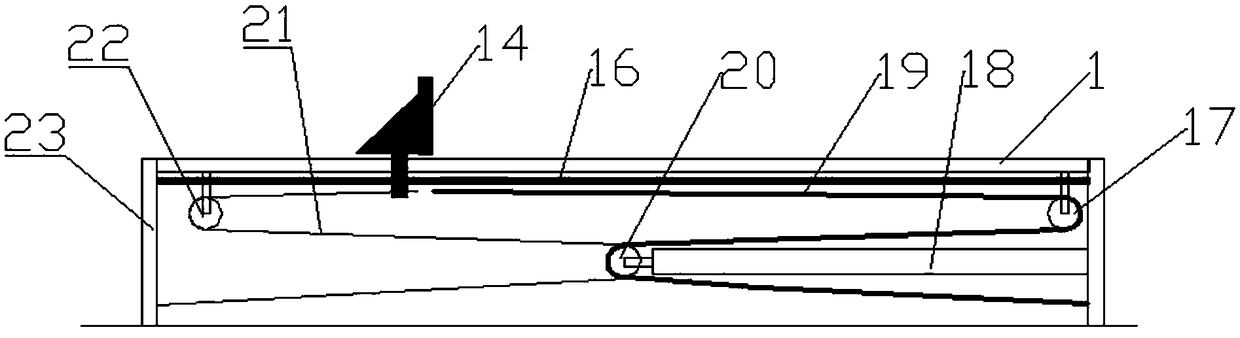

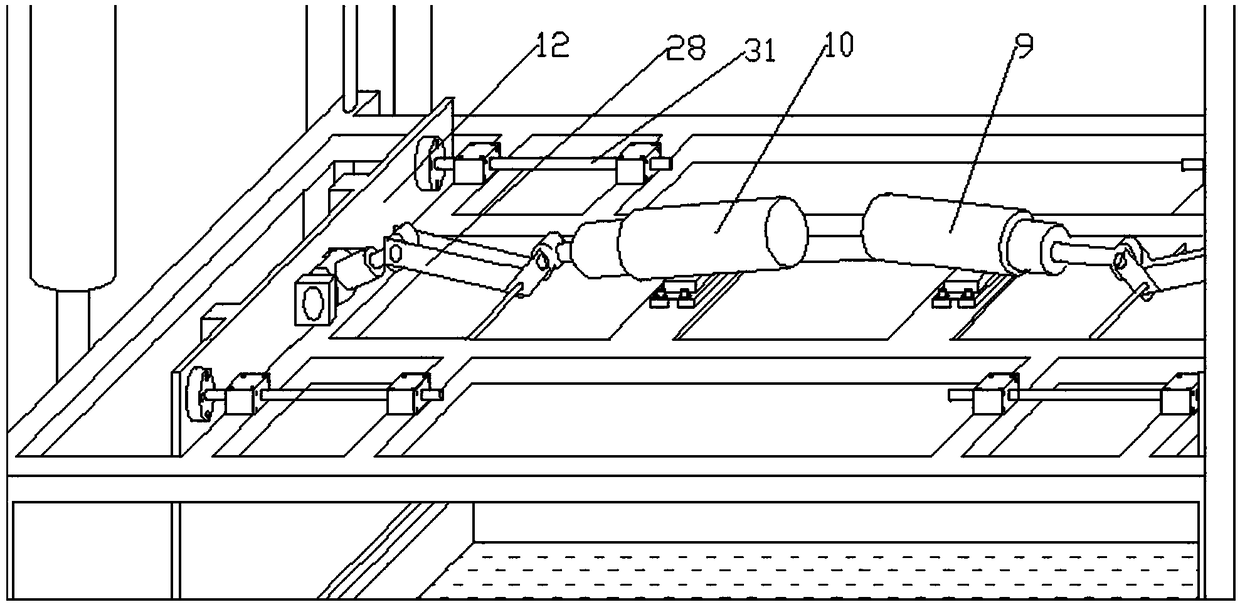

[0037] Such as Figure 1-3As shown, according to an embodiment of the hydraulic automatic feeding crusher of the present invention, it includes a feeding mechanism, an auxiliary bed mechanism, and a main bed mechanism. The auxiliary bed mechanism is connected to the main bed mechanism, and the feeding mechanism is arranged on the auxiliary bed mechanism One end away from the main bed mechanism, the auxiliary bed mechanism includes a bed surface 1, a first push plate 14, a first fixed pulley 22, a second fixed pulley 17, an oil wire 21, and a chain 19, and the two ends of the bed surface 1 Support frames 23 are respectively fixed, and rails 16 are respectively arranged on both sides below the bed surface 1, and the two ends of the rails 16 are respectively fixedly connected with adjacent support frames 23, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com